Introduction to PCB Printers

Printed Circuit Board (PCB) printers have revolutionized the electronics industry by enabling rapid prototyping and small-scale production of PCBs. These printers allow users to create custom PCBs in-house, reducing lead times and costs associated with outsourcing PCB Fabrication. In this article, we will compare different types of PCB printers to help you determine which one is better suited for your needs.

What is a PCB Printer?

A PCB printer is a specialized machine that deposits conductive and insulating materials onto a substrate to create a functional printed circuit board. These printers use various technologies, such as inkjet printing, dispensing, or screen printing, to create the desired circuit patterns on the substrate.

Benefits of Using a PCB Printer

- Rapid prototyping: PCB printers enable users to quickly create and test Prototype PCBs, reducing development time.

- Cost-effective: In-house PCB Printing eliminates the need for outsourcing, reducing costs associated with small-scale production runs.

- Customization: PCB printers allow for easy customization of PCB designs, enabling users to create application-specific boards.

- Confidentiality: By keeping PCB fabrication in-house, companies can maintain confidentiality and protect their intellectual property.

Types of PCB Printers

There are several types of PCB printers available in the market, each with its own advantages and disadvantages. Let’s explore the most common types:

Inkjet PCB Printers

Inkjet PCB printers use a modified inkjet printing technology to deposit conductive ink onto a substrate. These printers are known for their high resolution and ability to create fine traces and spacing.

Advantages of Inkjet PCB Printers

- High resolution: Inkjet printers can achieve trace widths as small as 50 microns, enabling the creation of dense and complex PCB designs.

- Versatility: Inkjet printers can work with a variety of substrates, including flexible materials like polyimide.

- Ease of use: Inkjet printers are relatively easy to operate and maintain, making them suitable for both beginners and experienced users.

Disadvantages of Inkjet PCB Printers

- Limited material options: Inkjet printers rely on specialized conductive inks, which may have lower conductivity compared to traditional copper traces.

- Slower printing speed: Inkjet printers may have slower printing speeds compared to other technologies, especially for larger PCBs.

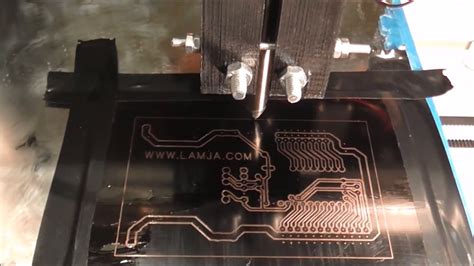

Dispensing PCB Printers

Dispensing PCB printers use a precision dispensing system to deposit conductive paste or ink onto a substrate. These printers are known for their ability to create thicker traces and their compatibility with a wide range of materials.

Advantages of Dispensing PCB Printers

- Thicker traces: Dispensing printers can create traces with a higher aspect ratio, enabling the creation of high-current carrying traces.

- Material compatibility: Dispensing printers can work with a variety of conductive materials, including silver-filled epoxies and low-temperature solders.

- 3D printing capabilities: Some dispensing printers can also create 3D structures, such as encapsulation or component embedding.

Disadvantages of Dispensing PCB Printers

- Lower resolution: Dispensing printers typically have lower resolution compared to inkjet printers, with minimum trace widths around 200 microns.

- Higher material costs: The conductive pastes and inks used in dispensing printers can be more expensive than traditional Copper-Clad Laminates.

Screen Printing PCB Printers

Screen printing PCB printers use a stencil-like screen to transfer conductive ink onto a substrate. These printers are known for their ability to create thick traces and their high throughput.

Advantages of Screen Printing PCB Printers

- Thick traces: Screen printing can create traces with a thickness of up to 100 microns, making them suitable for high-power applications.

- High throughput: Screen printing is a relatively fast process, enabling higher production volumes compared to other PCB printing technologies.

- Durability: Screen-printed traces are generally more durable and resistant to wear and tear compared to inkjet or dispensed traces.

Disadvantages of Screen Printing PCB Printers

- Lower resolution: Screen printing has a lower resolution compared to inkjet printing, with minimum trace widths around 100 microns.

- Limited design complexity: Screen printing may not be suitable for highly complex PCB designs with fine features and spacing.

- Higher setup costs: Creating screens for each PCB design can be time-consuming and add to the overall setup costs.

Comparison Table

| PCB Printer Type | Resolution (Minimum Trace Width) | Trace Thickness | Material Compatibility | Printing Speed | Ease of Use | Setup Costs |

|---|---|---|---|---|---|---|

| Inkjet | High (50 microns) | Thin | Limited | Slow | Easy | Low |

| Dispensing | Medium (200 microns) | Thick | Wide range | Medium | Moderate | Medium |

| Screen Printing | Low (100 microns) | Thick | Limited | Fast | Moderate | High |

Factors to Consider When Choosing a PCB Printer

When selecting a PCB printer, there are several factors to consider based on your specific requirements:

- Resolution and feature size: If your PCB designs require fine traces and spacing, an inkjet printer may be the best choice.

- Trace thickness: For high-current carrying applications, dispensing or screen printing printers may be more suitable due to their ability to create thicker traces.

- Material compatibility: Consider the materials you plan to use and ensure that the chosen printer is compatible with those materials.

- Production volume: For higher production volumes, screen printing printers may be more efficient due to their faster printing speeds.

- Budget: Consider the initial investment and ongoing costs associated with each type of printer, including equipment, materials, and maintenance.

Frequently Asked Questions (FAQ)

-

Q: Can PCB printers create multi-layer PCBs?

A: Some advanced PCB printers can create multi-layer PCBs by printing and laminating multiple layers together. However, the process is more complex and may require additional equipment and expertise. -

Q: How do the costs of in-house PCB printing compare to outsourcing?

A: In-house PCB printing can be more cost-effective for small-scale production runs and rapid prototyping. However, for larger production volumes, outsourcing to a dedicated PCB manufacturer may be more economical. -

Q: What is the learning curve for operating a PCB printer?

A: The learning curve varies depending on the type of printer and the user’s experience level. Inkjet printers are generally easier to operate, while dispensing and screen printing printers may require more training and experience. -

Q: Can PCB printers create solder mask and silkscreen layers?

A: Some advanced PCB printers can create solder mask and silkscreen layers using specialized inks or by integrating additional printing processes. However, these features may not be available on all PCB printers. -

Q: How durable are printed PCBs compared to traditionally manufactured ones?

A: The durability of printed PCBs depends on the materials and printing technology used. Screen-printed traces are generally more durable, while inkjet and dispensed traces may be more susceptible to wear and tear. However, with proper design and material selection, printed PCBs can be made to withstand various environmental conditions.

Conclusion

Choosing the right PCB printer depends on your specific requirements, such as resolution, trace thickness, material compatibility, production volume, and budget. Inkjet printers offer high resolution and ease of use, while dispensing printers provide thicker traces and material versatility. Screen printing printers are known for their high throughput and trace durability.

By carefully considering these factors and evaluating the advantages and disadvantages of each type of printer, you can select the best PCB printer for your needs. Investing in an in-house PCB printer can significantly reduce lead times, costs, and improve the overall efficiency of your electronics development process.

Leave a Reply