What is a PCB Substrate?

A Printed Circuit Board (PCB) substrate is the foundation material upon which the circuit pattern is printed and the electronic components are mounted. The substrate provides mechanical support and electrical insulation for the circuit. It is a crucial component in the manufacturing of PCBs, as it determines the performance, reliability, and cost of the final product.

Types of PCB Substrates

There are various types of PCB substrates available, each with its own unique properties and applications. Some of the most common PCB substrates include:

- FR-4 (Flame Retardant 4)

- Polyimide

- Teflon

- Ceramic

- Metal Core PCBs (MCPCBs)

FR-4 (Flame Retardant 4)

FR-4 is the most widely used PCB substrate material. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 has good mechanical strength, electrical insulation properties, and flame retardancy. It is suitable for a wide range of applications, from consumer electronics to industrial equipment.

| Property | Value |

|---|---|

| Dielectric Constant | 4.2 – 4.5 |

| Dissipation Factor | 0.02 |

| Thermal Conductivity | 0.3 W/mK |

| Tg (Glass Transition Temperature) | 130°C – 140°C |

| CTE (Coefficient of Thermal Expansion) | 14-16 ppm/°C |

Polyimide

Polyimide is a high-performance polymer substrate that offers excellent thermal stability, chemical resistance, and mechanical strength. It is often used in applications that require high reliability and the ability to withstand harsh environments, such as aerospace, automotive, and military electronics.

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 |

| Dissipation Factor | 0.002 |

| Thermal Conductivity | 0.2 W/mK |

| Tg (Glass Transition Temperature) | 260°C |

| CTE (Coefficient of Thermal Expansion) | 20 ppm/°C |

Teflon

Teflon, or Polytetrafluoroethylene (PTFE), is a fluoropolymer substrate known for its low dielectric constant, low dissipation factor, and high thermal stability. It is an ideal choice for high-frequency applications, such as RF and microwave circuits, where signal integrity is crucial.

| Property | Value |

|---|---|

| Dielectric Constant | 2.1 |

| Dissipation Factor | 0.0002 |

| Thermal Conductivity | 0.25 W/mK |

| Tg (Glass Transition Temperature) | 327°C |

| CTE (Coefficient of Thermal Expansion) | 100-120 ppm/°C |

Ceramic

Ceramic substrates, such as Alumina (Al2O3) and Aluminum Nitride (AlN), offer excellent thermal conductivity, high mechanical strength, and good electrical insulation properties. They are often used in high-power applications, such as LED lighting and power electronics, where efficient heat dissipation is essential.

| Property | Alumina (Al2O3) | Aluminum Nitride (AlN) |

|---|---|---|

| Dielectric Constant | 9.8 | 8.8 |

| Dissipation Factor | 0.0001 | 0.0005 |

| Thermal Conductivity | 20-30 W/mK | 150-180 W/mK |

| Flexural Strength | 350-400 MPa | 300-400 MPa |

| CTE (Coefficient of Thermal Expansion) | 6.5-7.5 ppm/°C | 4.5-5.5 ppm/°C |

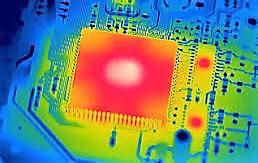

Metal Core PCBs (MCPCBs)

Metal Core PCBs (MCPCBs) are substrates that consist of a metal base, typically aluminum, with a thin layer of dielectric material and copper foil laminated on top. MCPCBs offer excellent thermal conductivity, allowing for efficient heat dissipation from power-hungry components. They are commonly used in applications such as LED lighting, automotive electronics, and power converters.

| Property | Value |

|---|---|

| Dielectric Constant | 4.0 – 4.5 |

| Thermal Conductivity (Aluminum Base) | 120-150 W/mK |

| Thermal Conductivity (Dielectric Layer) | 1-5 W/mK |

| CTE (Coefficient of Thermal Expansion) | 12-15 ppm/°C |

Factors to Consider When Choosing a PCB Substrate

When selecting a PCB substrate for your application, there are several factors to consider:

- Electrical Properties

- Dielectric Constant

- Dissipation Factor

-

Insulation Resistance

-

Thermal Properties

- Glass Transition Temperature (Tg)

- Coefficient of Thermal Expansion (CTE)

-

Thermal Conductivity

-

Mechanical Properties

- Flexural Strength

- Young’s Modulus

-

Dimensional Stability

-

Environmental Factors

- Operating Temperature Range

- Humidity Resistance

-

Chemical Resistance

-

Cost and Availability

- Raw Material Cost

- Manufacturing Cost

- Lead Time and Availability

PCB Substrate Manufacturing Process

The manufacturing process of PCB substrates typically involves the following steps:

- Raw Material Preparation

- Mixing and compounding of resin and filler materials

-

Impregnation of reinforcement materials (e.g., glass fibers) with resin

-

Lamination

- Layering of impregnated reinforcement materials and copper foils

-

Pressing the layers together under high temperature and pressure

-

Curing

-

Heating the laminated substrate to cross-link the resin and form a solid, stable material

-

Cutting and Sizing

- Cutting the cured substrate into the desired panel sizes

-

Optionally, pre-cutting the panels into smaller PCB sizes

-

Surface Finishing

- Cleaning and roughening the surface to improve adhesion of copper foil

- Applying surface treatments (e.g., solder mask, silkscreen) as required

Advanced PCB Substrate Technologies

In recent years, several advanced PCB substrate technologies have emerged to meet the growing demands for high-performance, high-density, and environmentally friendly electronics.

High Frequency Laminates

High-frequency laminates are designed to minimize signal loss and distortion in high-speed digital and RF applications. These laminates typically have low dielectric constants, low dissipation factors, and controlled impedance. Examples include Rogers RO4000 series, Isola I-Tera MT40, and Panasonic Megtron 6.

Halogen-Free Substrates

Halogen-free substrates are environmentally friendly alternatives to traditional FR-4 laminates, which contain brominated flame retardants. These substrates use non-halogenated flame retardants, reducing the environmental impact and complying with green initiatives such as RoHS and REACH. Examples include Isola DE156, Panasonic N-A-GH, and TUC-TU933.

Embedded Component Substrates

Embedded component substrates allow for the integration of passive components (e.g., resistors, capacitors) within the PCB substrate itself, saving space and improving performance. This technology enables the miniaturization of electronic devices and reduces the number of surface-mounted components. Examples include AT&S ECP® (Embedded Component Packaging) and LGIT EmCap (Embedded Capacitor).

Frequently Asked Questions (FAQ)

- What is the most common PCB substrate material?

-

FR-4 (Flame Retardant 4) is the most widely used PCB substrate material. It is a composite of woven fiberglass cloth impregnated with an epoxy resin binder, offering good mechanical strength, electrical insulation, and flame retardancy.

-

What are the advantages of using ceramic PCB substrates?

-

Ceramic PCB substrates, such as Alumina (Al2O3) and Aluminum Nitride (AlN), offer excellent thermal conductivity, high mechanical strength, and good electrical insulation properties. They are ideal for high-power applications that require efficient heat dissipation.

-

What factors should I consider when choosing a PCB substrate for my application?

-

When selecting a PCB substrate, consider factors such as electrical properties (dielectric constant, dissipation factor), thermal properties (glass transition temperature, thermal conductivity), mechanical properties (flexural strength, dimensional stability), environmental factors (operating temperature range, chemical resistance), and cost and availability.

-

What are Halogen-free PCB substrates, and why are they important?

-

Halogen-free PCB substrates are environmentally friendly alternatives to traditional FR-4 laminates, which contain brominated flame retardants. They use non-halogenated flame retardants, reducing the environmental impact and complying with green initiatives such as RoHS and REACH.

-

What are the benefits of using high-frequency laminates in PCB design?

- High-frequency laminates are designed to minimize signal loss and distortion in high-speed digital and RF applications. They typically have low dielectric constants, low dissipation factors, and controlled impedance, ensuring signal integrity and reliable performance in demanding applications.

In conclusion, understanding the properties, manufacturing process, and advanced technologies of PCB substrates is essential for designing and manufacturing high-quality, reliable electronic devices. By carefully considering the factors that influence substrate selection and staying up-to-date with the latest developments in the field, engineers and manufacturers can create PCBs that meet the ever-increasing demands of the electronics industry.

Leave a Reply