1. Streamlined Design Process

1.1 Use of CAD Tools

- Utilize advanced computer-aided design (CAD) software for PCB layout and design

- Ensure compatibility with manufacturing processes and equipment

- Implement design for manufacturability (DFM) principles

1.2 Standardized Design Rules

- Establish and adhere to a set of standardized design rules

- Maintain consistency across projects to reduce errors and delays

- Regularly update design rules based on manufacturing capabilities and industry standards

1.3 Design Review and Verification

- Conduct thorough design reviews to catch and correct errors early in the process

- Use automated design rule checks (DRC) and electrical rule checks (ERC)

- Collaborate with manufacturing teams to ensure design feasibility and optimize for production

2. Optimized Manufacturing Workflow

2.1 Lean Manufacturing Principles

- Implement lean manufacturing techniques to eliminate waste and optimize processes

- Continuously identify and address bottlenecks in the production flow

- Encourage a culture of continuous improvement and employee involvement

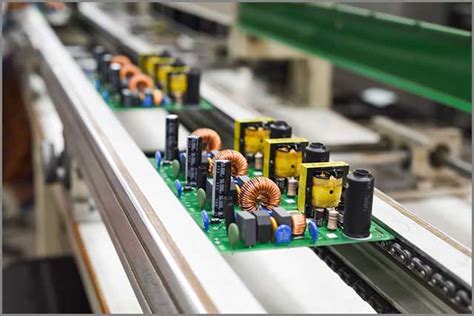

2.2 Automation and Robotics

- Invest in automated equipment for repetitive tasks such as pick-and-place, soldering, and inspection

- Utilize robotics for precise and consistent handling of PCBs throughout the manufacturing process

- Regularly maintain and upgrade equipment to ensure optimal performance

2.3 Parallel Processing

- Organize the manufacturing floor to enable parallel processing of PCBs

- Divide the production process into smaller, manageable stages

- Balance the workload across different stations to minimize idle time and maximize throughput

3. Effective Supply Chain Management

3.1 Strategic Supplier Partnerships

- Develop long-term relationships with reliable and quality-focused suppliers

- Collaborate with suppliers to ensure timely delivery of materials and components

- Establish clear communication channels and performance metrics with suppliers

3.2 Inventory Management

- Implement an efficient inventory management system to track and control stock levels

- Use just-in-time (JIT) inventory practices to reduce storage costs and minimize obsolescence

- Regularly review and adjust inventory levels based on demand forecasts and production schedules

3.3 Logistics and Transportation

- Optimize logistics and transportation routes to minimize lead times and costs

- Partner with reliable shipping carriers and customs brokers for international shipments

- Implement tracking systems to monitor the movement of materials and finished products

4. Quality Control and Testing

4.1 In-Process Quality Checks

- Perform regular quality inspections at various stages of the manufacturing process

- Use automated optical inspection (AOI) and X-ray inspection for non-visible defects

- Implement statistical process control (SPC) to monitor and control process variability

4.2 Functional Testing

- Conduct comprehensive functional testing to ensure PCB performance and reliability

- Develop and maintain a library of test programs for different PCB designs

- Use automated test equipment (ATE) for high-volume testing and faster throughput

4.3 Traceability and Documentation

- Maintain detailed records of quality control activities and test results

- Implement a traceability system to track PCBs throughout the manufacturing process

- Use electronic documentation systems for easy access and retrieval of quality-related data

5. Skilled Workforce and Training

5.1 Recruitment and Retention

- Attract and retain skilled technicians, engineers, and operators

- Offer competitive compensation packages and career growth opportunities

- Foster a positive work environment that encourages employee engagement and loyalty

5.2 Training and Development

- Provide ongoing training and development programs for employees

- Encourage cross-functional training to promote flexibility and adaptability

- Invest in training on new technologies, processes, and industry best practices

5.3 Knowledge Management

- Document and share knowledge across the organization

- Encourage collaboration and knowledge sharing among team members

- Implement a system for capturing and preserving institutional knowledge

6. Continuous Improvement and Innovation

6.1 Process Optimization

- Regularly review and analyze manufacturing processes for improvement opportunities

- Encourage employee involvement in identifying and implementing process enhancements

- Use data analytics and metrics to drive decision-making and process optimization

6.2 Technology Adoption

- Stay up-to-date with the latest advancements in PCB manufacturing technologies

- Evaluate and invest in new equipment and software that can improve efficiency and quality

- Collaborate with technology providers and industry partners to pilot and implement new solutions

6.3 Benchmarking and Best Practices

- Benchmark performance against industry leaders and best practices

- Participate in industry associations and forums to learn from peers and share experiences

- Adapt and implement relevant best practices to drive continuous improvement

7. Customer Collaboration and Communication

7.1 Early Involvement and Design Support

- Engage with customers early in the design process to understand their requirements and constraints

- Provide design support and recommendations to optimize PCBs for manufacturing

- Use collaborative tools and platforms for seamless communication and data sharing

7.2 Prototyping and Sampling

- Offer rapid Prototyping Services to help customers validate their designs

- Provide high-quality samples for customer evaluation and testing

- Gather customer feedback and incorporate it into the manufacturing process

7.3 Customer Service and Support

- Maintain clear and responsive communication channels with customers

- Provide timely updates on order status and delivery schedules

- Offer technical support and assistance to address customer inquiries and issues

| Factor | Key Elements |

|---|---|

| Streamlined Design Process | – Use of CAD Tools – Standardized Design Rules – Design Review and Verification |

| Optimized Manufacturing Workflow | – Lean Manufacturing Principles – Automation and Robotics – Parallel Processing |

| Effective Supply Chain Management | – Strategic Supplier Partnerships – Inventory Management – Logistics and Transportation |

| Quality Control and Testing | – In-Process Quality Checks – Functional Testing – Traceability and Documentation |

| Skilled Workforce and Training | – Recruitment and Retention – Training and Development – Knowledge Management |

| Continuous Improvement and Innovation | – Process Optimization – Technology Adoption – Benchmarking and Best Practices |

| Customer Collaboration and Communication | – Early Involvement and Design Support – Prototyping and Sampling – Customer Service and Support |

Frequently Asked Questions (FAQ)

1. What is the average turnaround time for FastPCBManufacturing?

The average turnaround time for FastPCBManufacturing varies depending on the complexity of the PCB design, the volume of the order, and the manufacturing capabilities of the provider. However, most FastPCBManufacturing services aim to deliver PCBs within 24 to 72 hours for standard designs and small to medium volumes.

2. How can I ensure my PCB design is optimized for fast manufacturing?

To optimize your PCB design for fast manufacturing, consider the following tips:

– Use standard component sizes and packages

– Maintain adequate spacing between components and traces

– Avoid complex and unnecessary features

– Follow the manufacturer’s design guidelines and rules

– Conduct thorough design reviews and verifications before submitting for production

3. What are the benefits of using automated equipment in PCB manufacturing?

Automated equipment in PCB manufacturing offers several benefits, including:

– Increased precision and consistency in component placement and soldering

– Faster production speeds and higher throughput

– Reduced human error and variability

– Improved quality and reliability of the finished PCBs

– Cost savings through reduced labor and increased efficiency

4. How can I select the right FastPCBManufacturing partner?

When selecting a FastPCBManufacturing partner, consider the following factors:

– Manufacturing capabilities and technology

– Quality control processes and certifications

– Turnaround times and delivery options

– Customer support and communication

– Pricing and value-added services

– Industry reputation and customer references

5. What role does supply chain management play in FastPCBManufacturing?

Effective supply chain management is crucial for FastPCBManufacturing as it ensures the timely availability of materials and components needed for production. Key aspects of supply chain management include:

– Building strong relationships with reliable suppliers

– Implementing efficient inventory management practices

– Optimizing logistics and transportation to minimize lead times

– Monitoring and managing supply chain risks and disruptions

– Collaborating with suppliers to drive continuous improvement and innovation

By focusing on these seven important factors, PCB Manufacturers can streamline their processes, improve efficiency, and deliver high-quality PCBs to their customers in the shortest possible time. FastPCBManufacturing is a critical capability in today’s competitive electronics industry, and companies that master these factors will be well-positioned for success.

Leave a Reply