Introduction to LED PCBs

Light-emitting diode (LED) printed circuit boards (PCBs) are specialized boards designed to support and connect LED components. These PCBs are essential for creating efficient and reliable LED lighting systems, found in a wide range of applications such as automotive lighting, home and office illumination, and industrial equipment.

What are LED PCBs?

LED PCBs are circuit boards specifically designed to accommodate LED components and their associated circuitry. They provide a stable platform for mounting LEDs and ensure proper electrical connections between components. LED PCBs are typically made from materials such as FR-4, aluminum, or ceramic, depending on the specific requirements of the application.

Benefits of Using LED PCBs

Using LED PCBs offers several advantages over traditional wiring methods:

- Compact design: LED PCBs allow for a more compact and organized arrangement of components, reducing the overall size of the lighting system.

- Improved heat dissipation: PCBs can be designed with thermal management features, such as Metal Core PCBs (MCPCBs), to effectively dissipate heat generated by LEDs, ensuring optimal performance and longevity.

- Enhanced reliability: Properly designed LED PCBs minimize the risk of electrical failures and ensure stable connections between components, resulting in a more reliable lighting system.

- Simplified assembly: LED PCBs streamline the assembly process by providing a standardized platform for mounting components, reducing manufacturing time and costs.

Designing LED PCBs

Key Considerations for LED PCB Design

When designing LED PCBs, several key factors must be considered to ensure optimal performance and reliability:

- LED selection: Choose appropriate LED components based on factors such as color, brightness, viewing angle, and power requirements.

- Thermal management: Design the PCB to effectively dissipate heat generated by LEDs, using techniques such as thermal vias, copper pours, and metal core PCBs (MCPCBs).

- Power distribution: Ensure that the PCB layout provides even power distribution to all LED components, minimizing voltage drops and current imbalances.

- Signal integrity: Maintain proper signal integrity by minimizing electromagnetic interference (EMI) and ensuring appropriate trace widths and spacing.

LED PCB Layout Guidelines

To create an efficient and reliable LED PCB layout, follow these guidelines:

- Place LEDs strategically to achieve the desired illumination pattern and intensity.

- Use appropriate trace widths to handle the required current for each LED.

- Minimize trace lengths to reduce voltage drops and power losses.

- Incorporate thermal management features, such as thermal vias and copper pours, to dissipate heat effectively.

- Follow the manufacturer’s recommendations for LED placement and spacing to ensure optimal performance and longevity.

LED PCB Design Software

Several PCB design software options are available for creating LED PCBs, including:

- Altium Designer

- KiCad

- Eagle

- OrCAD

- Cadence Allegro

These software tools offer features specifically tailored for LED PCB design, such as component libraries, thermal analysis tools, and design rule checks (DRCs).

LED PCB Fabrication

PCB Material Selection

Choosing the appropriate PCB material is crucial for LED applications. Common materials include:

- FR-4: A cost-effective, glass-reinforced epoxy laminate suitable for general-purpose LED applications.

- Metal Core PCBs (MCPCBs): PCBs with a metal core, typically aluminum, that provides excellent thermal conductivity for heat dissipation in high-power LED applications.

- Ceramic PCBs: Offer superior thermal performance and dimensional stability, ideal for high-temperature and high-reliability LED applications.

PCB Fabrication Process

The LED PCB fabrication process involves several steps:

- Preparing the PCB design files: Generate Gerber files and drill files from the PCB design software.

- PCB layup: Stack and align the required layers of the PCB material.

- Lamination: Apply heat and pressure to bond the layers together.

- Drilling: Drill holes for component mounting and vias.

- Copper plating: Plate the drilled holes and surface with copper to create conductive paths.

- Etching: Remove unwanted copper to form the desired circuit pattern.

- Solder mask application: Apply a protective solder mask layer to the PCB surface.

- Silkscreen printing: Print component labels and other markings on the PCB surface.

- Surface finish application: Apply a surface finish, such as HASL, ENIG, or OSP, to protect the exposed copper and improve solderability.

Quality Control and Testing

To ensure the quality and reliability of the fabricated LED PCBs, several quality control and testing procedures are implemented:

- Visual inspection: Inspect the PCBs for any visible defects or anomalies.

- Electrical testing: Perform continuity and insulation resistance tests to verify the integrity of the electrical connections.

- Functional testing: Test the PCBs with the mounted LED components to ensure proper operation and performance.

LED PCB Assembly

LED Mounting Techniques

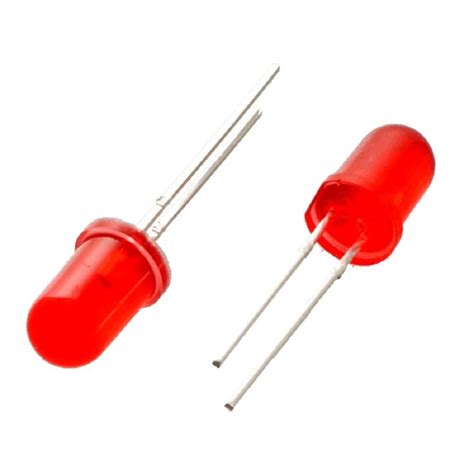

There are several techniques for mounting LEDs on PCBs:

- Through-hole mounting: LEDs with long leads are inserted through holes in the PCB and soldered on the opposite side.

- Surface mount (SMT): LEDs with short leads or no leads are mounted directly onto the PCB surface using solder paste and a reflow oven.

- Chip-on-board (COB): LED chips are directly mounted onto the PCB and wire-bonded to the circuit.

Soldering Methods

Soldering is a crucial step in the LED PCB assembly process. Common soldering methods include:

- Wave soldering: A wave of molten solder is applied to the bottom side of the PCB, suitable for through-hole components.

- Reflow soldering: Solder paste is applied to the PCB pads, and the board is heated in a reflow oven to melt the solder and bond the components to the PCB, suitable for surface mount components.

- Hand soldering: Manual soldering using a soldering iron, suitable for small-scale or prototype assembly.

Assembly Process Flow

The LED PCB assembly process typically follows these steps:

- Solder paste application: Apply solder paste to the PCB pads using a stencil or screen printing process (for SMT components).

- Component placement: Place the LED components onto the PCB, either manually or using automated pick-and-place machines.

- Soldering: Solder the components to the PCB using the appropriate soldering method (wave, reflow, or hand soldering).

- Inspection and testing: Visually inspect the assembled PCBs and perform functional tests to ensure proper operation.

- Conformal coating (optional): Apply a protective coating to the assembled PCB to enhance durability and resistance to environmental factors.

Best Practices for LED PCB Assembly

To ensure a successful LED PCB assembly process, follow these best practices:

- Use appropriate soldering techniques and parameters for the specific components and PCB materials.

- Ensure proper component placement and orientation.

- Implement electrostatic discharge (ESD) protection measures to prevent damage to sensitive components.

- Follow the manufacturer’s guidelines for handling and storage of LED components.

- Conduct thorough inspections and testing to identify and address any assembly issues.

Thermal Management in LED PCBs

Importance of Thermal Management

Proper thermal management is critical in LED PCBs to ensure optimal performance, reliability, and longevity of the LED components. LEDs generate heat during operation, and excessive heat can lead to reduced light output, color shifts, and premature failure.

Thermal Design Considerations

When designing LED PCBs for effective thermal management, consider the following factors:

- PCB material: Choose materials with high thermal conductivity, such as metal core PCBs (MCPCBs) or ceramic PCBs, to facilitate heat dissipation.

- Thermal vias: Incorporate thermal vias to provide a path for heat to transfer from the LED components to the PCB’s heat-dissipating layers.

- Copper pours: Use copper pours on the PCB Layers to increase the thermal mass and improve heat spreading.

- LED placement: Optimize LED placement to ensure even heat distribution and minimize thermal stress on individual components.

- Heatsinks: Consider using external heatsinks or thermally conductive adhesives to further enhance heat dissipation from the PCB.

Thermal Simulation and Analysis

Thermal simulation and analysis tools can be used to predict and optimize the thermal performance of LED PCBs. These tools allow designers to:

- Model the heat generation and dissipation in the PCB assembly.

- Identify potential thermal hotspots and areas of concern.

- Evaluate the effectiveness of various thermal management strategies.

- Optimize the PCB layout and component placement for improved thermal performance.

Popular thermal simulation and analysis software include Ansys Icepak, Mentor Graphics FloTHERM, and Autodesk Fusion 360.

LED PCB Testing and Quality Assurance

Electrical Testing

Electrical testing is performed to verify the functionality and reliability of the LED PCB assembly. Common electrical tests include:

- Continuity testing: Verifies that the intended electrical connections are present and unintended connections (shorts) are absent.

- Insulation resistance testing: Measures the resistance between isolated conductors to ensure adequate insulation.

- Voltage and current measurements: Verifies that the LED components receive the appropriate voltage and current levels for optimal operation.

Optical Testing

Optical testing is crucial for evaluating the performance and quality of LED PCBs. Key optical parameters to test include:

- Luminous flux: Measures the total amount of light emitted by the LED assembly.

- Color temperature: Verifies that the LEDs produce the desired color temperature (e.g., warm white, cool white).

- Color rendering index (CRI): Assesses the ability of the LEDs to accurately represent colors compared to a reference light source.

- Beam angle: Measures the angular distribution of light emitted by the LED assembly.

Optical testing equipment, such as integrating spheres, spectroradiometers, and goniometers, is used to perform these measurements.

Environmental Testing

Environmental testing ensures that the LED PCBs can withstand the intended operating conditions and maintain performance over their expected lifespan. Common environmental tests include:

- Temperature cycling: Subjects the PCBs to repeated cycles of high and low temperatures to evaluate their thermal stability and resistance to thermal stress.

- Humidity testing: Exposes the PCBs to high humidity levels to assess their resistance to moisture and potential corrosion.

- Vibration and shock testing: Evaluates the mechanical robustness of the PCBs and their ability to withstand vibration and shock loads.

Accelerated Life Testing (ALT)

Accelerated life testing (ALT) is used to predict the long-term reliability and performance of LED PCBs by subjecting them to elevated stress levels (e.g., higher temperatures, currents, or humidity) for a shorter duration. ALT helps identify potential failure modes and estimate the expected lifespan of the LED assembly under normal operating conditions.

Troubleshooting and Debugging LED PCBs

Common Issues in LED PCBs

Several common issues can arise in LED PCBs, including:

- LED failure: Individual LEDs may fail due to manufacturing defects, thermal stress, or electrical overstress.

- Uneven illumination: Non-uniform light output across the LED array can result from improper LED placement, electrical imbalances, or thermal gradients.

- Color inconsistency: Variations in color temperature or hue between individual LEDs can occur due to binning differences or thermal effects.

- Flickering or strobing: Intermittent or pulsating light output can be caused by electrical noise, driver issues, or loose connections.

Debugging Techniques

When troubleshooting LED PCBs, follow these debugging techniques:

- Visual inspection: Carefully inspect the PCB for any visible defects, such as damaged components, solder bridges, or poor solder joints.

- Voltage and current measurements: Use a multimeter or oscilloscope to measure the voltage and current at key points in the circuit to identify any deviations from expected values.

- Thermal imaging: Employ thermal imaging cameras or thermocouples to identify hot spots or uneven temperature distribution across the PCB.

- Signal analysis: Use an oscilloscope to analyze the electrical signals driving the LEDs, looking for any anomalies or distortions that may indicate underlying issues.

Repair and Rework

If issues are identified during troubleshooting, repair and rework may be necessary. Common repair and rework techniques for LED PCBs include:

- Component replacement: Remove and replace faulty LED components using appropriate desoldering and soldering techniques.

- Solder joint rework: Reflow or rework problematic solder joints to ensure proper electrical and mechanical connections.

- Trace repair: Repair damaged or broken traces using conductive epoxy, jumper wires, or micro-soldering techniques.

- Firmware updates: If the issue is related to the LED driver or control firmware, updating or modifying the firmware may resolve the problem.

Frequently Asked Questions (FAQ)

-

Q: What are the advantages of using LED PCBs over traditional lighting methods?

A: LED PCBs offer several advantages, including compact design, improved heat dissipation, enhanced reliability, and simplified assembly compared to traditional lighting methods. -

Q: What factors should I consider when selecting PCB materials for LED applications?

A: When choosing PCB materials for LED applications, consider factors such as thermal conductivity, electrical insulation, mechanical stability, and cost. Common materials include FR-4, metal core PCBs (MCPCBs), and ceramic PCBs. -

Q: How can I ensure proper thermal management in my LED PCB design?

A: To ensure proper thermal management in LED PCB designs, use thermally conductive PCB materials, incorporate thermal vias and copper pours, optimize LED placement, and consider using external heatsinks or thermally conductive adhesives. -

Q: What are the most common LED mounting techniques for PCB assembly?

A: The most common LED mounting techniques for PCB assembly include through-hole mounting, surface mount (SMT), and chip-on-board (COB) mounting. -

Q: What types of testing should I perform to ensure the quality and reliability of my LED PCBs?

A: To ensure the quality and reliability of LED PCBs, perform electrical testing (continuity, insulation resistance, voltage/current measurements), optical testing (luminous flux, color temperature, CRI, beam angle), environmental testing (temperature cycling, humidity, vibration/shock), and accelerated life testing (ALT).

Conclusion

LED PCBs play a crucial role in the development of efficient, reliable, and compact LED lighting systems. By understanding the key aspects of LED PCB design, fabrication, assembly, thermal management, and testing, engineers and manufacturers can create high-quality LED products that meet the demands of various applications.

When designing LED PCBs, it is essential to consider factors such as LED selection, thermal management, power distribution, and signal integrity. Following best practices for PCB layout and using appropriate design software can help streamline the design process and ensure optimal performance.

The fabrication and assembly of LED PCBs involve careful material selection, precise manufacturing processes, and thorough quality control and testing procedures. Proper soldering techniques, component placement, and ESD protection are critical for successful assembly.

Effective thermal management is paramount in LED PCBs to ensure long-term reliability and performance. Employing thermally conductive materials, incorporating thermal vias and copper pours, and using thermal simulation and analysis tools can help optimize the thermal design.

Comprehensive testing, including electrical, optical, environmental, and accelerated life testing, is essential for validating the quality and reliability of LED PCBs. When issues arise, systematic troubleshooting and debugging techniques, along with appropriate repair and rework methods, can help resolve problems effectively.

By adhering to best practices and staying up-to-date with the latest advancements in LED PCB technology, designers and manufacturers can create innovative, high-performance LED lighting solutions that meet the ever-evolving needs of the market.

Leave a Reply