What are PCB Components?

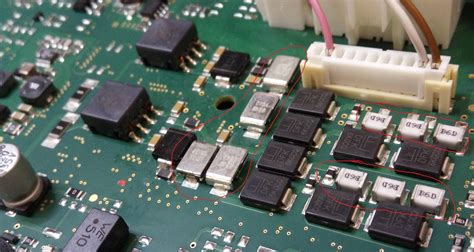

PCB components are electronic parts that are mounted on a printed circuit board to create a functional electronic device. These components are connected through conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

Types of PCB Components

There are two main categories of PCB components:

-

Through-Hole Components: These components have long leads that are inserted into holes drilled in the PCB and soldered to pads on the opposite side.

-

Surface Mount Components: These components are mounted directly onto the surface of the PCB using solder paste and are typically smaller than through-hole components.

Common PCB Components

Resistors

Resistors are passive two-terminal components that resist the flow of electric current. They are used to control voltage levels, divide voltages, and limit current in a circuit. Resistors come in various types, such as:

- Fixed Resistors

- Variable Resistors

- SMD Resistors

| Resistor Type | Description |

|---|---|

| Fixed | Have a fixed resistance value |

| Variable | Resistance can be adjusted (e.g., potentiometers) |

| SMD | Surface-mount resistors for compact designs |

Capacitors

Capacitors are passive two-terminal components that store electrical energy in an electric field. They are used for filtering, coupling, decoupling, and energy storage in electronic circuits. Common types of capacitors include:

- Ceramic Capacitors

- Electrolytic Capacitors

- Tantalum Capacitors

| Capacitor Type | Description |

|---|---|

| Ceramic | Compact, high-frequency, low-value capacitors |

| Electrolytic | Polarized, high-capacitance, low-frequency |

| Tantalum | Polarized, high-capacitance, low-leakage |

Inductors

Inductors are passive two-terminal components that store energy in a magnetic field when electric current flows through them. They are used for filtering, noise suppression, and energy storage in electronic circuits. Types of inductors include:

- Air Core Inductors

- Ferrite Core Inductors

- SMD Inductors

Diodes

Diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction. They are used for rectification, voltage regulation, and protection in electronic circuits. Common types of diodes include:

- Rectifier Diodes

- Zener Diodes

- Schottky Diodes

- Light-Emitting Diodes (LEDs)

Transistors

Transistors are semiconductor devices that can amplify or switch electronic signals. They are the building blocks of modern electronics and are used in a wide range of applications, from simple switches to complex integrated circuits. The two main types of transistors are:

- Bipolar Junction Transistors (BJTs)

- Field-Effect Transistors (FETs)

Integrated Circuits (ICs)

Integrated circuits are miniaturized electronic circuits that consist of multiple components, such as transistors, diodes, resistors, and capacitors, fabricated on a single semiconductor substrate. ICs are used in various applications, from simple logic gates to complex microprocessors and memory devices. Examples of ICs include:

- Operational Amplifiers (Op-Amps)

- Microcontrollers

- Memory Chips

Connectors

Connectors are components that allow electronic devices to be connected to other devices or power sources. They come in various shapes and sizes, depending on the application and the type of connection required. Some common types of connectors include:

- USB Connectors

- HDMI Connectors

- Power Connectors

- Header Connectors

Switches

Switches are mechanical or electronic components that can make or break an electrical connection. They are used to control the flow of current in a circuit and can be operated manually or automatically. Types of switches include:

- Toggle Switches

- Pushbutton Switches

- DIP Switches

- Relay Switches

Oscillators and Crystals

Oscillators and crystals are components that generate periodic electronic signals. They are used for timing, clock generation, and frequency reference in electronic circuits. The two main types are:

- Crystal Oscillators

- Ceramic Resonators

Transformers

Transformers are passive electrical devices that transfer electrical energy between two or more circuits through electromagnetic induction. They are used for voltage and current conversion, isolation, and impedance matching in electronic circuits. Types of transformers include:

- Power Transformers

- Audio Transformers

- RF Transformers

Sensors

Sensors are devices that detect and respond to physical stimuli, such as light, heat, motion, or pressure, and convert them into electrical signals. They are used in various applications, from simple temperature monitoring to complex industrial process control. Examples of sensors include:

- Temperature Sensors

- Pressure Sensors

- Accelerometers

- Gyroscopes

Fuses and Circuit Breakers

Fuses and circuit breakers are safety devices that protect electronic circuits from excessive current or voltage. They interrupt the flow of current when it exceeds a predetermined level, preventing damage to the components and the device. The two main types are:

- Cartridge Fuses

- Resettable Fuses (PTC)

PCB Component Selection and Placement

When designing a PCB, selecting the right components and placing them correctly on the board is crucial for the proper functioning and reliability of the device. Some factors to consider when selecting and placing PCB components include:

- Electrical characteristics (e.g., voltage rating, current rating, tolerance)

- Physical size and shape

- Thermal properties

- Electromagnetic compatibility (EMC)

- Manufacturing constraints (e.g., solderability, assembly process)

Proper component placement can minimize signal interference, reduce noise, and improve the overall performance of the device. It is also essential to follow the manufacturer’s recommendations and industry standards when selecting and placing components on a PCB.

PCB Component Soldering Techniques

Soldering is the process of joining electronic components to a PCB using a low-melting-point metal alloy called solder. There are two main soldering techniques used for PCB components:

-

Through-Hole Soldering: This technique involves inserting the component leads through holes in the PCB and soldering them to pads on the opposite side. Through-hole soldering can be done manually using a soldering iron or automatically using wave soldering machines.

-

Surface Mount Soldering: This technique involves placing the components directly onto solder paste-coated pads on the PCB surface and then heating the board to melt the solder and form a permanent connection. Surface mount soldering is typically done using reflow ovens or vapor phase soldering machines.

Proper soldering techniques, temperature control, and the use of appropriate solder alloys are essential for creating reliable and durable solder joints.

PCB Component Testing and Inspection

After the components are soldered to the PCB, it is essential to test and inspect the board to ensure proper functionality and reliability. Some common testing and inspection methods include:

-

Visual Inspection: Checking for proper component placement, orientation, and soldering quality using magnification or automated optical inspection (AOI) systems.

-

In-Circuit Testing (ICT): Using specialized test fixtures to verify the presence, orientation, and functionality of individual components on the PCB.

-

Functional Testing: Verifying the overall functionality of the assembled PCB by applying input signals and measuring output responses.

-

Boundary Scan Testing: Using built-in test circuitry (e.g., JTAG) to test the interconnections and functionality of components on the PCB.

Regular testing and inspection help identify and resolve issues early in the manufacturing process, reducing costs and improving the overall quality of the final product.

Frequently Asked Questions (FAQ)

-

What is the difference between through-hole and surface mount components?

Through-hole components have long leads that are inserted into holes drilled in the PCB and soldered to pads on the opposite side, while surface mount components are mounted directly onto the surface of the PCB using solder paste. -

What factors should I consider when selecting PCB components?

When selecting PCB components, consider factors such as electrical characteristics, physical size and shape, thermal properties, electromagnetic compatibility, and manufacturing constraints. -

What are the main soldering techniques used for PCB components?

The two main soldering techniques used for PCB components are through-hole soldering and surface mount soldering. Through-hole soldering involves inserting component leads through holes in the PCB and soldering them to pads on the opposite side, while surface mount soldering involves placing components directly onto solder paste-coated pads on the PCB surface and heating the board to melt the solder. -

Why is PCB component testing and inspection important?

PCB component testing and inspection are essential for ensuring the proper functionality and reliability of the assembled board. Regular testing and inspection help identify and resolve issues early in the manufacturing process, reducing costs and improving the overall quality of the final product. -

What are some common testing and inspection methods for PCB components?

Common testing and inspection methods for PCB components include visual inspection, in-circuit testing (ICT), functional testing, and boundary scan testing. These methods help verify the presence, orientation, functionality, and interconnections of components on the PCB.

Conclusion

PCB components form the foundation of modern electronics, enabling the creation of diverse devices that power our world. Understanding the types, functions, and applications of these components is crucial for anyone involved in electronic design, manufacturing, or maintenance. By selecting the right components, placing them correctly on the board, and employing proper soldering, testing, and inspection techniques, designers and manufacturers can create reliable, high-quality electronic devices that meet the ever-growing demands of the industry.

Leave a Reply