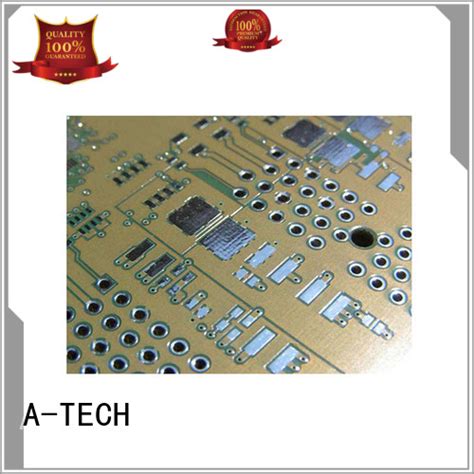

What is OSP PCB?

OSP (Organic Solderability Preservative) is a surface finish applied to printed circuit boards (PCBs) to protect the exposed copper from oxidation and ensure excellent solderability. OSP PCB is a cost-effective and environmentally friendly alternative to other surface finishes like HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and Immersion Silver.

How does OSP work?

OSP is a water-based organic compound that selectively bonds to the exposed copper on the PCB, forming a thin, transparent layer. This layer acts as a barrier, preventing the copper from oxidizing and maintaining its solderability for a limited period. The OSP coating is typically applied through a process called “flood and squeeze,” where the PCB is immersed in the OSP solution and then passed through a set of rollers to remove excess solution.

Advantages of OSP PCB Surface Finish

- Cost-effective: OSP is one of the most economical surface finishes available, making it an attractive option for high-volume production.

- Environmentally friendly: Unlike other surface finishes that involve heavy metals like lead or nickel, OSP is a water-based organic compound that is RoHS compliant and eco-friendly.

- Excellent solderability: OSP provides good wetting properties and ensures reliable solder joints, making it suitable for various soldering processes, including reflow and wave soldering.

- Flat surface: The thin OSP layer maintains the flatness of the PCB surface, making it ideal for fine-pitch components and high-density designs.

- Easy to inspect: The transparent nature of the OSP coating allows for easy visual inspection of the PCB, simplifying quality control processes.

Disadvantages of OSP PCB Surface Finish

- Limited shelf life: OSP-coated PCBs have a shorter shelf life compared to other surface finishes, typically around 6-12 months, depending on storage conditions.

- Susceptible to handling damage: The thin OSP layer can be easily damaged by improper handling, leading to exposed copper and potential solderability issues.

- Not suitable for multiple reflow cycles: OSP may degrade after multiple reflow cycles, affecting the solderability of the PCB.

- Incompatible with some cleaning processes: Certain cleaning processes, such as those involving alkaline cleaners, can strip away the OSP coating.

OSP vs. Other PCB Surface Finishes

When choosing a surface finish for your PCB, it’s essential to consider the specific requirements of your application. Here’s a comparison of OSP with other common surface finishes:

| Surface Finish | Cost | Shelf Life | Solderability | Environmental Impact |

|---|---|---|---|---|

| OSP | Low | 6-12 months | Good | Low |

| HASL | Low | 12+ months | Good | High (lead content) |

| ENIG | High | 12+ months | Excellent | Moderate |

| Immersion Silver | Moderate | 12+ months | Excellent | Low |

OSP vs. HASL

HASL (Hot Air Solder Leveling) is another cost-effective surface finish that involves dipping the PCB in a molten solder bath and then using hot air to level the surface. While HASL offers good solderability and a longer shelf life than OSP, it has some drawbacks:

- HASL can result in an uneven surface, making it unsuitable for fine-pitch components.

- The high temperatures involved in the HASL process can cause thermal stress on the PCB.

- HASL often contains lead, which is not environmentally friendly and may not comply with RoHS regulations.

OSP vs. ENIG

ENIG (Electroless Nickel Immersion Gold) is a high-end surface finish that provides excellent solderability and a long shelf life. However, ENIG has some disadvantages compared to OSP:

- ENIG is significantly more expensive than OSP, making it less suitable for cost-sensitive applications.

- The ENIG process involves the use of nickel, which can cause allergic reactions in some individuals.

- ENIG-coated PCBs may be prone to “black pad” issues, where the nickel layer separates from the copper, leading to solderability problems.

OSP vs. Immersion Silver

Immersion Silver is another RoHS-compliant surface finish that offers excellent solderability and a relatively long shelf life. However, compared to OSP, Immersion Silver has some limitations:

- Immersion Silver is more expensive than OSP, although still more affordable than ENIG.

- Silver can tarnish over time, especially when exposed to sulfur-containing environments, which can affect solderability.

- Immersion Silver may not be suitable for applications exposed to high humidity, as it can lead to silver migration and potential electrical shorts.

Choosing the Right OSP PCB Surface Finish

When deciding whether OSP is the right surface finish for your PCB, consider the following factors:

- Application requirements: Evaluate the environmental conditions, expected shelf life, and soldering processes involved in your application.

- Cost considerations: OSP is a cost-effective option, making it suitable for high-volume production and price-sensitive projects.

- Component compatibility: Ensure that the components used in your design are compatible with the OSP surface finish and the specified soldering process.

- Manufacturing capabilities: Verify that your PCB manufacturer has experience working with OSP and can consistently produce high-quality OSP-coated boards.

Best Practices for Handling and Storing OSP PCBs

To maximize the shelf life and maintain the solderability of OSP-coated PCBs, follow these best practices:

- Store OSP PCBs in a cool, dry environment with a temperature range of 20-30°C and a relative humidity of 40-60%.

- Use moisture barrier bags (MBBs) with desiccants to protect OSP PCBs from moisture and contaminants during storage and transportation.

- Handle OSP PCBs with care, using gloves to avoid contaminating the surface with oils and other contaminants from the skin.

- Minimize the exposure of OSP PCBs to high temperatures and humidity, as these conditions can accelerate the degradation of the OSP coating.

- Use OSP PCBs within the recommended shelf life to ensure optimal solderability and assembly performance.

FAQ

-

Q: How long does the OSP surface finish last?

A: The shelf life of OSP-coated PCBs is typically 6-12 months, depending on storage conditions. Proper handling and storage can help maximize the shelf life of OSP PCBs. -

Q: Can OSP be used for both reflow and wave soldering?

A: Yes, OSP is suitable for various soldering processes, including reflow and wave soldering. However, OSP may degrade after multiple reflow cycles, affecting solderability. -

Q: Is OSP compatible with all types of PCB cleaning processes?

A: No, certain cleaning processes, particularly those involving alkaline cleaners, can strip away the OSP coating. It’s essential to choose cleaning processes that are compatible with OSP. -

Q: How does OSP compare to other surface finishes in terms of cost?

A: OSP is one of the most cost-effective surface finishes available, making it an attractive option for high-volume production and price-sensitive projects. -

Q: Can OSP be used for high-density PCB designs with fine-pitch components?

A: Yes, the thin and flat nature of the OSP coating makes it suitable for fine-pitch components and high-density PCB designs. However, proper handling is crucial to avoid damaging the OSP layer.

In conclusion, OSP is a cost-effective and environmentally friendly PCB surface finish that offers good solderability and compatibility with various soldering processes. While it has some limitations, such as a shorter shelf life and susceptibility to handling damage, OSP remains a popular choice for many applications. By understanding the advantages and disadvantages of OSP and following best practices for handling and storage, you can effectively incorporate OSP into your PCB designs and ensure optimal assembly performance.

Leave a Reply