Introduction

When it comes to flat flexible cables, two common types are often compared: FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit). While they may look similar at first glance, there are some key differences between FFC and FPC in terms of their construction, applications, and properties. In this article, we’ll dive deep into FFC vs FPC to understand how they differ and which one is best suited for various uses.

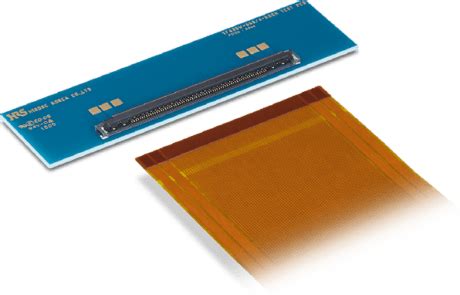

What is a Flat Flexible Cable (FFC)?

A flat flexible cable, or FFC, is a type of electrical cable that is flat and flexible as the name implies. It consists of multiple conductors running parallel to each other, embedded within a thin insulating material such as plastic. The conductors are usually made of copper or tinned copper and can range in number from a few to several dozen depending on the cable width and pitch (spacing between conductors).

FFCs are designed to provide electrical interconnections between different parts of electronic devices or between a device and external components. Their flat and flexible nature allows them to fit in tight spaces, fold around corners, and flex during operation without damaging the conductors. This makes FFCs ideal for applications where space is limited and flexibility is required, such as in laptops, cell phones, printers, and various consumer electronics.

Advantages of FFCs

- Very thin and lightweight

- Highly flexible and can bend in any direction

- Can be folded or creased without damaging conductors

- Easy to route in tight spaces

- Lower cost compared to other cable types

- Available in various lengths, widths, and pin counts

Disadvantages of FFCs

- Limited current carrying capacity due to thin conductors

- Not suitable for high-speed or high-frequency signals

- Susceptible to electromagnetic interference (EMI)

- Connectors can be fragile and prone to damage

- Requires specialized connectors and termination methods

What is a Flexible Printed Circuit (FPC)?

A flexible printed circuit, or FPC, is a type of printed circuit board (PCB) that is designed to be flexible. Unlike traditional rigid PCBs, FPCs are made from thin, flexible insulating materials such as polyimide or polyester, with conductive traces printed or etched onto the surface. The conductive traces are usually made of copper and can be coated with a protective layer to prevent oxidation and improve durability.

FPCs can be single-sided (with conductors on one side), double-sided (with conductors on both sides), or even multi-layered for more complex designs. They can also incorporate various electronic components such as resistors, capacitors, and ICs, making them more versatile than simple cables.

The main advantage of FPCs is their ability to combine the functionality of a printed circuit board with the flexibility of a cable. This allows designers to create more compact and lightweight electronic devices by eliminating the need for separate PCBs and cables. FPCs are commonly used in applications such as medical devices, automotive electronics, aerospace systems, and wearable technology.

Advantages of FPCs

- Can integrate electronic components directly onto the circuit

- Allows for more complex circuit designs and routing

- Provides better signal integrity and EMI shielding compared to FFCs

- Can handle higher current and power levels

- More durable and resistant to environmental factors

- Enables 3D packaging of electronics

Disadvantages of FPCs

- Higher cost compared to FFCs due to more complex manufacturing process

- Requires specialized design and layout skills

- Limited flexibility compared to FFCs, cannot be sharply bent or folded

- May require stiffeners or supports in some applications

- Heavier than FFCs due to additional layers and components

Key Differences Between FFC and FPC

Now that we have a basic understanding of what FFCs and FPCs are, let’s summarize the main differences between them:

| Property | FFC | FPC |

|---|---|---|

| Construction | Flat cable with parallel conductors | Flexible printed circuit board |

| Flexibility | Highly flexible, can be bent or folded | Moderately flexible, cannot be sharply bent |

| Components | Cannot integrate electronic components | Can integrate various electronic components |

| Signal Integrity | Susceptible to EMI and signal loss | Better signal integrity and EMI shielding |

| Current Capacity | Limited due to thin conductors | Can handle higher current and power levels |

| Durability | Conductors can be damaged by excessive bending | More durable and resistant to environmental factors |

| Cost | Lower cost due to simpler construction | Higher cost due to complex manufacturing process |

| Applications | Interconnections in tight spaces, consumer electronics | Compact and lightweight electronic devices, medical and industrial applications |

As you can see, while FFCs and FPCs serve similar purposes in providing electrical interconnections, they have distinct characteristics that make them suitable for different applications. FFCs are best for simple interconnections where high flexibility and low cost are prioritized, while FPCs are better suited for more complex designs that require integration of components and better electrical performance.

Applications of FFC and FPC

FFC Applications

- Laptop computers (connecting display, keyboard, touchpad)

- Cell phones and tablets (connecting display, camera, battery)

- Printers and scanners (connecting print head, sensors)

- Digital cameras (connecting lens, image sensor, flash)

- DVD and Blu-ray players (connecting optical pickup unit)

- Automotive electronics (connecting sensors, displays)

- Industrial automation (connecting sensors, actuators)

FPC Applications

- Medical devices (hearing aids, pacemakers, insulin pumps)

- Wearable technology (smartwatches, fitness trackers)

- Aerospace systems (avionics, satellites, drones)

- Military equipment (radios, night vision devices)

- Automotive electronics (dashboard displays, control modules)

- Industrial equipment (robotics, machine vision systems)

- Consumer electronics (VR/AR headsets, gaming controllers)

Choosing Between FFC and FPC

When deciding whether to use an FFC or FPC in your application, there are several factors to consider:

-

Flexibility requirements: If your design requires the cable to be extremely flexible or able to fold sharply, an FFC may be the better choice. FPCs have more limited flexibility due to their multi-layer construction and component integration.

-

Electrical performance: If your application involves high-speed signals, high currents, or sensitive analog signals, an FPC may provide better signal integrity and noise immunity compared to an FFC. The shielding layers and controlled impedance of FPCs can help mitigate EMI and signal loss.

-

Space constraints: Both FFCs and FPCs are designed to save space compared to traditional round cables, but FFCs may be thinner and easier to route in very tight spaces. FPCs can be more space-efficient overall by integrating components directly onto the circuit.

-

Durability: If your application involves repeated flexing, exposure to harsh environments, or mechanical stresses, an FPC may be more durable than an FFC. The polyimide substrate and protective coatings used in FPCs provide better resistance to abrasion, chemicals, and extreme temperatures.

-

Cost: FFCs are generally less expensive than FPCs due to their simpler construction and manufacturing process. However, the total cost of ownership should be considered, including any additional connectors, assemblies, or reliability issues that may arise from using FFCs in demanding applications.

FAQ

Can FFCs and FPCs be used interchangeably?

In some cases, FFCs and FPCs can be used interchangeably if they have compatible connectors and electrical specifications. However, they are not always direct substitutes due to differences in flexibility, durability, and signal integrity. It’s important to carefully evaluate the requirements of your application before choosing between an FFC or FPC.

How are FFCs and FPCs typically terminated?

FFCs are typically terminated using zero insertion force (ZIF) connectors that clamp onto the end of the cable. The connectors have a lever or slider that opens and closes the contacts, allowing the cable to be inserted or removed easily.

FPCs can be terminated using various methods depending on the application, including ZIF connectors, board-to-board connectors, or direct soldering to a PCB. In some cases, the FPC may have a stiffener or reinforcement added to the end to facilitate insertion into a connector.

What are the most common pitches for FFCs and FPCs?

The most common pitches for FFCs are 0.5mm, 1.0mm, and 1.25mm, with finer pitches down to 0.3mm available for high-density applications. The pitch refers to the distance between the centers of adjacent conductors.

FPCs can have a wider range of pitches depending on the trace width and spacing, but common values are 0.5mm, 0.8mm, 1.0mm, and 1.27mm. FPCs with very fine pitches down to 0.2mm or less are used in some advanced applications.

How do FFCs and FPCs handle power transmission?

FFCs have limited current carrying capacity due to the thinness of the conductors, typically around 0.5A to 1A per conductor. The total current capacity of the cable depends on the number of conductors and the ambient temperature.

FPCs can handle higher power levels than FFCs due to the use of thicker copper traces and multiple layers. The current capacity of an FPC depends on the trace width, thickness, and number of layers, but can range from a few amps to tens of amps in some cases. FPCs can also incorporate dedicated power and ground planes for better power distribution.

What are some common failure modes for FFCs and FPCs?

Some common failure modes for FFCs include:

– Conductor breakage due to repeated flexing or sharp bending

– Insulation damage or delamination exposing conductors

– Connector damage or misalignment causing intermittent contact

– Solder joint failure at terminations due to stress or fatigue

Common failure modes for FPCs include:

– Trace cracking or delamination due to excessive flexing or mechanical stress

– Coverlay or Solder Mask Damage exposing traces

– Component failure due to flexing, shock, or vibration

– Solder joint failure at component leads or terminations

– Contamination or corrosion of exposed conductors

Proper design, handling, and strain relief can help mitigate these failure modes and ensure reliable operation of FFCs and FPCs in demanding applications.

Conclusion

In summary, while FFCs and FPCs may look similar, they have distinct differences in terms of construction, flexibility, electrical performance, durability, and cost. FFCs are best suited for simple interconnections in tight spaces where high flexibility is required, while FPCs offer better signal integrity, power handling, and component integration for more complex applications.

When choosing between an FFC or FPC, designers must carefully consider the specific requirements of their application, including the mechanical, electrical, and environmental constraints. By understanding the strengths and limitations of each type of cable, designers can make informed decisions that optimize performance, reliability, and cost in their products.

As technology continues to advance, both FFCs and FPCs will play important roles in enabling the next generation of electronic devices, from consumer gadgets to medical implants to space exploration. By staying up-to-date on the latest developments in flexible circuit technology, designers can push the boundaries of what is possible and create innovative solutions to meet the challenges of the future.

Leave a Reply