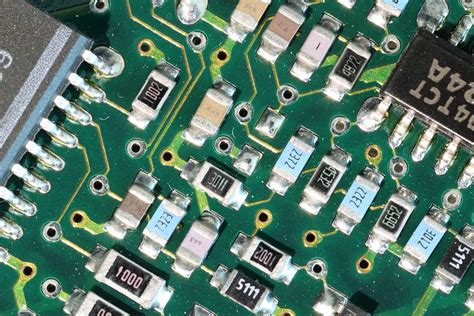

What Are PCB Prototypes?

PCB Prototypes are early versions of printed circuit boards used to test and validate a design before mass production. Prototyping allows engineers to check the functionality, performance, and manufacturability of a PCB design. It helps identify any issues or improvements needed before investing in large-scale fabrication.

Key aspects of PCB prototypes include:

- Verifying the schematic design

- Testing component placement and routing

- Evaluating signal integrity and power delivery

- Checking mechanical fit and assembly

- Validating manufacturing processes

Prototyping is a critical step in the PCB Development cycle that saves time and money by catching problems early. It allows faster iterations to perfect the design and streamline the transition to volume production.

Why Are PCB Prototypes Important?

PCB prototypes serve several important purposes in the product development process:

1. Proof-of-Concept

The first prototype proves that the core functionality works as intended. It shows that the circuit design is sound and the selected components are compatible. The initial prototype may not have the final form factor but it demonstrates the key concepts.

2. Design Validation

As the design progresses, prototypes are used to thoroughly test and validate all aspects of the PCB:

| Aspect | Testing |

|---|---|

| Schematic | Verifying the logical connections and component values are correct |

| Layout | Checking physical footprints, placement, routing, and manufacturability |

| Signal Integrity | Measuring critical signals to ensure quality and avoid issues like crosstalk |

| Power Integrity | Confirming power delivery to components meets specs without noise |

| Thermal | Monitoring temperatures and heat dissipation |

| Mechanical | Evaluating fit, structural integrity, and ease of assembly |

| Firmware/Software | Developing and debugging the code that runs on the PCB |

Thorough prototype testing identifies design flaws to be corrected before finalizing the PCB.

3. Manufacturing Optimization

Prototypes are used to refine the production process:

- Testing different materials and surface finishes

- Trying alternate suppliers or components

- Optimizing machine settings and tooling

- Dialing in assembly and inspection procedures

Building prototypes with the actual manufacturing methods provides a realistic assessment of product quality, yield, and cost. Issues found here can still be corrected by changing the design or processes before ramping to volume.

4. Compliance Certification

Some prototypes are used for certification and compliance testing to regulatory and industry standards:

- Electromagnetic compatibility (EMC)

- Safety

- Environmental

- Reliability

Accredited test labs use representative prototypes to perform these evaluations. Passing is required to legally sell the final product.

5. Sales and Marketing Samples

Prototypes make great visual aids for customer presentations, trade shows, photo shoots, and other sales and marketing activities. An attractive physical model beats an abstract slide deck. These looks-like/works-like prototypes need to be cosmetically accurate with the final casings and interfaces.

How Many PCB Prototype Iterations Are Typical?

The number of prototype spins varies depending on the project complexity and how much prior experience the team has in that type of design. But in general, most PCBs go through 3-5 major iterations:

-

Proof-of-concept (POC) – The initial prototype to demonstrate core functionality. May be hand-wired or use a quick PCB layout.

-

Engineering Validation Test (EVT) – A more refined prototype with complete schematics and layouts. Used for full functional testing and early certification trials.

-

Design Validation Test (DVT) – The final prototype that should be very close to the production version. Used to validate all changes from EVT and do final compliance testing.

-

Production Validation Test (PVT) – Pilot run on actual mass production equipment and processes. Used to validate assembly and quality before full production ramp.

-

Production – The final, stable design verified by all the previous steps. Continuously monitored for quality and yield.

Some simple designs may combine steps while highly complex ones may need additional sub-steps. But the general flow from POC to EVT/DVT to PVT to Production holds for most PCB projects.

What Are Common PCB Prototype Mistakes to Avoid?

PCB designers can save a lot of time, money, and headaches by steering clear of these common prototyping pitfalls:

1. Rushed Design

Don’t shortcut schematic design, component research, and PCB layout in the rush to get a prototype. Careful design work pays for itself in fewer iterations.

2. Incomplete Documentation

Prototypes should be well documented with:

- Full schematics

- Bill-of-materials (BOM)

- Assembly drawings

- Fabrication files

- Test procedures

Missing documentation causes confusion and rework in prototyping and production.

3. Inadequate Testing

Test as thoroughly as practical at each prototype stage. Rigorous bench testing saves debug time later. Consider compliance scans before committing to full certification.

4. Ignoring DFM

Choose components and design for manufacturability (DFM) from the start. Substituting parts or redoing layouts to fix manufacturing issues wastes prototyping cycles.

5. Out-of-Sync Revisions

Use PCB CAD tools to manage design revisions and change control. Ensure all documentation and files are kept current for each prototype iteration. Out-of-sync BOMs or Gerbers cause expensive scrap and delays.

6. Cheaping Out

Don’t cut corners on prototypes to save a few bucks. Quality boards, parts, and assembly pay for themselves in reduced debugging. Free PCB design tools quickly hit capability and capacity limits.

What Are Some Advanced PCB prototyping Techniques?

Experienced PCB designers employ these advanced techniques to streamline prototyping and jump-start the transition to production:

1. Rapid Prototyping

3D printers and additive manufacturing can produce PCB-like structures and non-conductive casings within hours. Rapid PCB fabrication services can deliver simple boards in 1-2 days. Getting physical models quickly provides valuable feedback for electrical and mechanical design.

2. Modular Design

Partitioning a complex system into modular subsystems with clean interfaces allows development and testing in parallel. Proven modules can be reused across products. Modular designs adapt more readily to component obsolescence.

3. Scalable Architecture

Planning for a range of product tiers with varying cost/performance from a common baseline enables faster prototyping and rollout. Scalable architectures reuse proven circuit blocks and layouts across a family of products.

4. Design for Test (DFT)

Incorporating test points, programming headers, instrumentation ports, and self-test features makes prototypes easier to debug. DFT hooks save time in board bring-up and system integration. They provide a foundation for production test fixtures and procedures.

5. Co-Design with Manufacturing

Collaborating closely with the manufacturer throughout prototyping provides a smoother transition to mass production. Assemblers can suggest design-for-manufacturing (DFM) improvements to boost yield and quality. Fabless semiconductor companies co-design prototype silicon with their foundry to ensure a successful tapeout.

6. Concurrent Engineering

Developing the enclosures, packaging, accessories, documentation, and support in parallel with PCB prototyping accelerates the complete product introduction. Frequent coordination keeps all the pieces in sync. Unified product lifecycle management (PLM) tools can help integrate mechanical, electrical, and software development.

FAQ

How much do PCB prototypes cost?

Prototype costs vary widely depending on the PCB size, layer count, components, and quantity. Simple 2-layer boards might cost $10-$50 each in small volumes. Mid-size 4-6 layer boards average $100-$500. Large, complex boards with 8+ layers, high-speed interfaces, or RF sections can run $1000-$5000 or more. Setup and non-recurring engineering (NRE) fees can add hundreds to thousands of dollars. But overall, PCB prototypes are a bargain compared to the cost of a failed product launch.

How long does it take to get PCB prototypes?

PCB prototype lead times range from 1 day to 4 weeks depending on complexity:

| Service | Layers | Lead Time |

|---|---|---|

| Rapid | 1-2 | 1-5 days |

| Standard | 2-6 | 5-10 days |

| Advanced | 6-12 | 10-15 days |

| Complex | 12+ | 15-20 days |

| Specialty | Rigid-flex, exotic materials | 20-30 days |

These are rough estimates. Actual turnaround depends on design completeness, part availability, and manufacturing workload. Expedites are sometimes possible for a fee.

What are the differences between PCB prototypes and production boards?

The main differences are in the materials, manufacturing processes, and testing:

| Aspect | Prototype | Production |

|---|---|---|

| Material | FR-4, standard Tg | Higher grade, IST |

| Soldermask | Any color | Pantone matched |

| Silkscreen | Basic legend | Custom graphics |

| Tolerances | Looser | Tighter |

| Finish | HASL, lead-free HASL | ENIG, IAg, Osp |

| Electrical Test | Flying probe | Fixtureless, boundary scan |

| Quality | Visual inspection | AOI, X-ray |

| Traceability | Minimal | Full, serialized |

Prototypes use standard materials and processes for speed and low cost. Production boards use higher grade materials and tighter controls for reliability and repeatability at volume.

Do I need to use the same manufacturer for prototypes and production?

No, but there are benefits to using the same manufacturer for both:

- Familiarity with your design intent

- Ability to optimize the design for their processes

- Leverage prototype tooling and setup for production

- Smoother transition from prototype to production

- Volume pricing on materials and components

If you do use separate prototype and production shops, be sure the proto vendor uses similar processes as your production partner. Major changes in materials, stackups, or design rules will invalidate the prototypes.

How do I choose a PCB Prototype Manufacturer?

Key criteria for selecting a PCB prototype partner include:

- Technical capabilities that match your needs

- Experience in your industry/application

- Responsive service and support

- Domestic vs. offshore location

- NRE/tooling charges and piece part price

- Quick-turn and expedite options

- Design for manufacturing (DFM) assistance

- Transition to production services

Get quotes from 3-5 qualified shops. Check references, tour facilities, and try them out on a smaller project before awarding a critical program.

Leave a Reply