What is BGA Reballing?

BGA (Ball Grid Array) reballing is a process of replacing the solder balls on a BGA chip or package. This process is often necessary when the original solder balls have been damaged or have deteriorated, causing issues with the device’s functionality. Reballing involves removing the old solder balls, cleaning the pads, and then applying new solder balls to the package.

The Importance of BGA Reballing

BGA reballing is crucial for many industries, including:

- Electronics manufacturing

- Aerospace

- Automotive

- Medical devices

- Consumer electronics

Without proper BGA reballing, devices may experience:

- Intermittent failures

- Complete device failure

- Reduced lifespan

- Decreased reliability

The BGA Reballing Process

The BGA reballing process typically involves the following steps:

-

Inspection: The device is inspected to determine the extent of the damage and the specific BGA package that needs to be reballed.

-

Removal: The old solder balls are removed using specialized equipment, such as a BGA Rework station or a hot air soldering iron.

-

Cleaning: The pads on the PCB and the BGA package are cleaned to remove any residue or oxidation.

-

Alignment: The BGA package is aligned with the PCB using specialized alignment tools to ensure proper placement.

-

Reballing: New solder balls are applied to the BGA package using a reballing stencil and solder paste.

-

Reflow: The device is heated to melt the new solder balls and create a strong connection between the BGA package and the PCB.

-

Inspection: The device is inspected again to ensure proper connectivity and functionality.

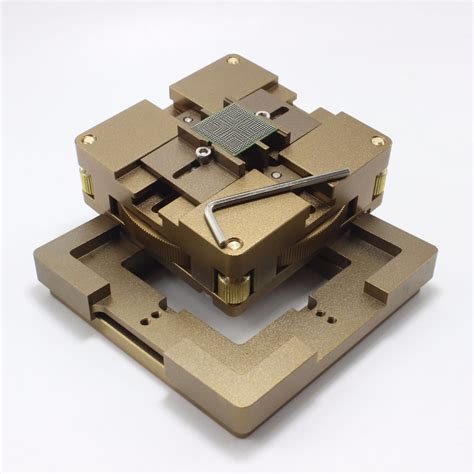

BGA Reballing Equipment

To perform BGA reballing, companies use specialized equipment, such as:

- BGA rework stations

- Hot air soldering irons

- Reballing stencils

- Solder paste

- Alignment tools

- Microscopes for inspection

Choosing a BGA Reballing Company

When selecting a BGA reballing company, consider the following factors:

Experience and Expertise

Look for a company with extensive experience in BGA reballing and a proven track record of success. The company should have expertise in working with various BGA packages and devices from different industries.

Equipment and Facilities

Ensure that the company has state-of-the-art equipment and facilities to perform BGA reballing effectively. They should invest in high-quality tools and maintain a clean, ESD-safe environment.

Quality Control and Testing

A reputable BGA reballing company should have strict quality control measures in place to ensure the accuracy and reliability of their work. They should also perform thorough testing to verify the functionality of the device after reballing.

Turnaround Time and Customer Service

Consider the company’s turnaround time and their ability to meet your deadlines. Additionally, evaluate their customer service and communication practices to ensure a smooth and satisfactory experience.

Top BGA Reballing Companies

Here are some of the top BGA reballing companies known for their expertise and quality of service:

| Company | Location | Industries Served |

|---|---|---|

| Acme BGA Reballing | New York, USA | Electronics, Aerospace, Medical |

| BGA Masters | London, UK | Automotive, Consumer Electronics |

| Reballpro | Shenzhen, China | Electronics Manufacturing, Medical Devices |

| TechFixers | Sydney, Australia | Consumer Electronics, Aerospace |

| BGA Solutions | Toronto, Canada | Electronics, Automotive, Medical |

Case Studies

Case Study 1: Acme BGA Reballing

Acme BGA Reballing was contacted by a medical device manufacturer who was experiencing intermittent failures in their devices. Upon inspection, Acme discovered that the BGA packages on the devices’ PCBs were damaged due to improper handling during the manufacturing process.

Acme’s team of experts performed BGA reballing on the affected devices using their state-of-the-art equipment and facilities. They successfully replaced the damaged solder balls and tested the devices to ensure proper functionality.

As a result of Acme’s BGA reballing service, the medical device manufacturer was able to avoid costly product recalls and maintain their reputation for producing high-quality, reliable devices.

Case Study 2: BGA Masters

BGA Masters was approached by an automotive electronics supplier who was facing issues with their engine control units (ECUs). The ECUs were experiencing complete failures, leading to vehicle breakdowns and customer complaints.

The BGA Masters team analyzed the ECUs and found that the BGA packages had deteriorated due to exposure to high temperatures and vibrations within the vehicle. They performed BGA reballing on the affected ECUs, replacing the old solder balls with new ones and ensuring proper alignment and connectivity.

Thanks to BGA Masters’ expertise, the automotive electronics supplier was able to resolve the issues with their ECUs, improve vehicle reliability, and maintain customer satisfaction.

Frequently Asked Questions (FAQ)

1. How long does the BGA reballing process take?

The duration of the BGA reballing process varies depending on the complexity of the device and the extent of the damage. On average, the process can take anywhere from a few hours to a couple of days.

2. Can all BGA packages be reballed?

Most BGA packages can be reballed, but some may be more challenging than others due to their size, design, or material composition. An experienced BGA reballing company should be able to handle a wide variety of BGA packages.

3. Is BGA reballing a permanent solution?

When performed correctly by a skilled technician using high-quality materials, BGA reballing can be a long-lasting solution. However, the durability of the repair also depends on factors such as the device’s operating conditions and handling.

4. How much does BGA reballing cost?

The cost of BGA reballing varies depending on the complexity of the device, the extent of the damage, and the reballing company’s pricing structure. On average, prices can range from $50 to $500 per device.

5. Can I perform BGA reballing myself?

While it is possible to perform BGA reballing yourself if you have the necessary equipment and skills, it is highly recommended to entrust this task to a professional BGA reballing company. Improper reballing can lead to further damage and costly repairs.

Conclusion

BGA reballing is a critical process for maintaining the functionality and reliability of electronic devices across various industries. By selecting a reputable BGA reballing company with the necessary expertise, equipment, and quality control measures, you can ensure that your devices are repaired effectively and efficiently.

When choosing a BGA reballing company, consider factors such as their experience, facilities, turnaround time, and customer service. By partnering with a trusted BGA reballing provider, you can minimize downtime, reduce costs, and maintain the high-quality performance of your electronic devices.

Leave a Reply