Introduction to Flexible PCBs and FlexPCBQuotes

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry by providing a versatile and reliable solution for interconnecting electronic components in various applications. Unlike traditional rigid PCBs, flexible PCBs offer the ability to bend, twist, and fold, making them ideal for devices that require compact packaging or dynamic movement. In this comprehensive article, we will explore the world of flexible PCBs and guide you through the process of obtaining accurate and competitive quotes for your flexible PCB projects.

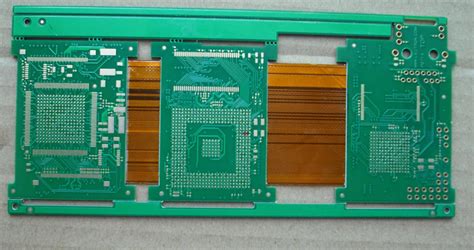

What are Flexible PCBs?

Flexible PCBs, also known as flex circuits or flex PCBs, are a type of printed circuit board that consists of a thin, flexible substrate made from materials such as polyimide or polyester. These substrates are laminated with conductive copper traces and covered with a protective layer, allowing the PCB to bend and flex without damaging the electrical connections.

Flexible PCBs offer several advantages over rigid PCBs:

-

Flexibility: The ability to bend and twist enables flexible PCBs to fit into tight spaces and conform to various shapes, making them suitable for applications with limited space or unique packaging requirements.

-

Durability: Flexible PCBs can withstand repeated bending and flexing without compromising the integrity of the electrical connections, ensuring long-term reliability.

-

Weight reduction: The thin and lightweight nature of flexible PCBs contributes to overall device weight reduction, which is crucial for portable and wearable electronics.

-

Improved signal integrity: Flexible PCBs can be designed with controlled impedance and shorter signal paths, minimizing signal loss and enhancing high-frequency performance.

Applications of Flexible PCBs

Flexible PCBs find applications in a wide range of industries and products, including:

-

Consumer electronics: Smartphones, tablets, laptops, wearables, and gaming devices often utilize flexible PCBs for their compact and lightweight designs.

-

Medical devices: Implantable devices, diagnostic equipment, and patient monitoring systems benefit from the flexibility and reliability of flex circuits.

-

Automotive electronics: Flexible PCBs are used in vehicle infotainment systems, sensors, and electronic control units (ECUs) to accommodate tight spaces and harsh environments.

-

Aerospace and defense: Avionics, satellites, and military equipment rely on flexible PCBs for their ability to withstand vibration, shock, and extreme temperatures.

-

Industrial automation: Robotics, motion control systems, and industrial sensors incorporate flexible PCBs for their durability and resistance to mechanical stress.

Understanding Flexible PCB Quotes

When embarking on a flexible PCB project, obtaining accurate and competitive quotes is essential for budget planning and ensuring the success of your project. However, understanding the factors that influence flexible PCB quotes can be challenging. In this section, we will break down the key elements that impact the cost of flexible PCBs and provide insights on how to navigate the quoting process effectively.

Factors Affecting Flexible PCB Quotes

Several factors contribute to the cost of flexible PCBs, and understanding these factors can help you make informed decisions when requesting quotes. The primary factors include:

-

Board size and shape: The dimensions and complexity of the flexible PCB design directly impact the manufacturing cost. Larger and more intricate shapes require more materials and processing time, resulting in higher quotes.

-

Number of layers: Flexible PCBs can have single or multiple layers, and the number of layers affects the cost. Multi-layer flexible PCBs are more expensive due to the additional materials and fabrication steps involved.

-

Material selection: The choice of substrate material, such as polyimide or polyester, and the copper weight influence the cost of flexible PCBs. Higher-grade materials and thicker copper layers generally result in higher quotes.

-

Quantity: The number of flexible PCBs you order plays a significant role in determining the unit cost. Higher quantities often lead to lower unit prices due to economies of scale and reduced setup costs.

-

Surface finish: The type of surface finish applied to the copper traces, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), affects the cost of flexible PCBs. Some finishes are more expensive than others due to the materials and processes involved.

-

Turnaround time: The urgency of your project can impact the quoted price. Faster turnaround times may incur additional charges, while longer lead times can result in lower quotes.

-

Design complexity: Features such as fine pitch components, high-density interconnects (HDI), and controlled impedance can increase the complexity of the flexible PCB design and, consequently, the manufacturing cost.

Requesting Flexible PCB Quotes

To obtain accurate and competitive quotes for your flexible PCB project, follow these steps:

-

Prepare detailed specifications: Provide comprehensive information about your flexible PCB requirements, including board size, number of layers, material preferences, surface finish, and any special features or constraints.

-

Generate Gerber files: Create accurate Gerber files that represent your flexible PCB design. Gerber files are industry-standard formats used by manufacturers to interpret and fabricate PCBs.

-

Research and select potential manufacturers: Identify reputable flexible PCB manufacturers that have experience in producing boards similar to your requirements. Consider factors such as manufacturing capabilities, quality standards, and customer support.

-

Submit RFQs (Request for Quotes): Reach out to the selected manufacturers and provide them with your detailed specifications and Gerber files. Be clear about your quantity requirements and desired turnaround time.

-

Review and compare quotes: Carefully analyze the received quotes, considering not only the price but also factors such as lead time, quality assurance processes, and additional services offered (e.g., assembly, testing, or packaging).

-

Communicate and clarify: If you have any questions or concerns about the quotes, engage in open communication with the manufacturers. Clarify any ambiguities and negotiate terms if necessary.

-

Make an informed decision: Based on your evaluation of the quotes and the manufacturers’ capabilities, select the supplier that offers the best combination of price, quality, and service for your flexible PCB project.

FlexPCBQuotes: Your Trusted Partner for Flexible PCB Quotes

FlexPCBQuotes is a leading online platform that simplifies the process of obtaining flexible PCB quotes from trusted manufacturers worldwide. By leveraging our extensive network of verified suppliers and advanced quoting system, we ensure that you receive accurate, competitive, and timely quotes for your flexible PCB projects.

Why Choose FlexPCBQuotes?

-

Extensive supplier network: We have partnered with a wide range of flexible PCB manufacturers across the globe, providing you with access to a diverse pool of suppliers with varying capabilities and specializations.

-

Verified and reliable manufacturers: All manufacturers in our network undergo a stringent verification process to ensure they meet our quality standards and have a proven track record of delivering high-quality flexible PCBs.

-

Streamlined quoting process: Our user-friendly platform allows you to submit your flexible PCB specifications and Gerber files effortlessly. We handle the distribution of your RFQs to multiple manufacturers, saving you time and effort.

-

Competitive pricing: By leveraging our purchasing power and long-standing relationships with manufacturers, we can secure competitive pricing for your flexible PCB projects, helping you optimize your budget.

-

Expert support: Our knowledgeable team of flexible PCB experts is available to provide guidance and support throughout the quoting process. We can assist you in refining your specifications, selecting the most suitable manufacturers, and resolving any technical issues.

-

Secure and confidential: We prioritize the security and confidentiality of your data. Your project details and Gerber files are securely stored and shared only with the selected manufacturers, ensuring the protection of your intellectual property.

How to Get Started with FlexPCBQuotes

Getting started with FlexPCBQuotes is simple and straightforward. Follow these steps to obtain flexible PCB quotes quickly and easily:

-

Sign up for an account: Visit our website and create a free account by providing your basic contact information and company details.

-

Create a new project: Once logged in, click on the “New Project” button and provide a name and description for your flexible PCB project.

-

Specify your requirements: Fill in the detailed specifications of your flexible PCB, including board size, number of layers, material preferences, surface finish, and any special features or constraints.

-

Upload Gerber files: Attach your Gerber files to the project. Our system supports various Gerber formats, ensuring compatibility with most CAD software.

-

Select manufacturers: Choose the manufacturers you want to receive quotes from. You can either select specific suppliers or let our system automatically match your project with suitable manufacturers based on your requirements.

-

Submit your RFQ: Review your project details and click the “Submit” button to send your RFQ to the selected manufacturers.

-

Receive and compare quotes: Within a short timeframe, you will receive quotes from the manufacturers. Our platform organizes the quotes in a clear and comparative format, allowing you to easily evaluate and compare the offers.

-

Communicate and finalize: If needed, you can communicate with the manufacturers directly through our platform to clarify any questions or negotiate terms. Once you have selected the most suitable supplier, you can proceed with placing your order.

Tips for Optimizing Flexible PCB Quotes

To ensure you receive the most favorable quotes for your flexible PCB projects, consider the following tips:

-

Design for manufacturability (DFM): Incorporate DFM principles into your flexible PCB design to minimize complexity and reduce manufacturing costs. Consult with experienced designers or manufacturers for guidance on optimizing your design.

-

Standardize materials and processes: When possible, opt for standard materials and processes that are readily available and commonly used in the industry. Custom materials or specialized processes can increase costs and lead times.

-

Consider panelization: If your project involves multiple small flexible PCBs, consider panelizing them into a single larger panel. Panelization can reduce manufacturing costs and improve production efficiency.

-

Plan ahead: Whenever possible, provide ample lead time for your flexible PCB projects. Rushing production can result in higher costs and potentially compromise quality.

-

Communicate clearly: Provide clear and detailed specifications to the manufacturers to avoid misunderstandings and ensure accurate quoting. Be responsive to any questions or clarifications requested by the suppliers.

-

Leverage volume discounts: If your project requires a large quantity of flexible PCBs, consider negotiating volume discounts with the manufacturers. Higher volumes often translate to lower unit costs.

-

Build long-term relationships: Establishing long-term relationships with reliable flexible PCB manufacturers can lead to better pricing, improved service, and priority treatment for your projects.

Conclusion

Flexible PCBs have become an indispensable component in the electronics industry, offering unparalleled versatility and reliability for a wide range of applications. When embarking on a flexible PCB project, obtaining accurate and competitive quotes is crucial for successful budget planning and project execution.

By understanding the factors that influence flexible PCB quotes and following best practices for requesting and evaluating quotes, you can navigate the quoting process effectively. FlexPCBQuotes provides a comprehensive solution for obtaining flexible PCB quotes from trusted manufacturers worldwide, streamlining the process and ensuring you receive the best value for your projects.

With the right approach and a reliable partner like FlexPCBQuotes, you can confidently bring your flexible PCB designs to life while optimizing costs and ensuring the highest quality standards.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity (MOQ) for flexible PCBs?

The minimum order quantity for flexible PCBs varies among manufacturers. Some suppliers may accept low-volume orders, while others require a higher MOQ. It’s best to check with individual manufacturers or consult FlexPCBQuotes for guidance on MOQ requirements. -

How long does it take to receive flexible PCB quotes?

The turnaround time for receiving flexible PCB quotes depends on the complexity of your project and the responsiveness of the manufacturers. Typically, you can expect to receive quotes within 24 to 48 hours after submitting your RFQ through FlexPCBQuotes. -

Can I request quotes for assembled flexible PCBs?

Yes, many flexible PCB manufacturers offer assembly services. When submitting your RFQ, specify whether you require bare boards or assembled boards, and provide the necessary assembly files and instructions. -

What file formats are required for flexible PCB quotes?

To obtain accurate flexible PCB quotes, you need to provide Gerber files that represent your PCB design. Gerber files are industry-standard formats used by manufacturers to interpret and fabricate PCBs. Additionally, include any necessary drill files, solder mask files, and silkscreen files. -

How can I ensure the quality of the flexible PCBs I receive?

To ensure the quality of your flexible PCBs, choose reputable manufacturers with proven track records and robust quality control processes. FlexPCBQuotes works with verified suppliers who adhere to strict quality standards. Additionally, consider requesting certifications, test reports, or samples before placing a full production order.

Leave a Reply