What is PCB Drilling?

PCB drilling is the process of creating holes in a printed circuit board (PCB) to allow for the insertion of electrical components and the creation of interconnections between layers. It is a critical step in the PCB fabrication process, as the accuracy and precision of the drilled holes can greatly impact the functionality and reliability of the final product.

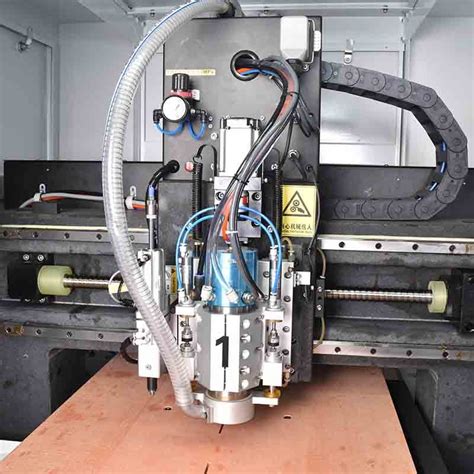

PCB drilling is typically performed using high-speed drill bits made of carbide or diamond, which are capable of creating holes with diameters as small as 0.1mm. The drilling process can be automated using computer numerical control (CNC) machines, which allow for highly precise and repeatable drilling patterns.

Why is Precise PCB Drilling Important?

Precise PCB drilling is essential for several reasons:

-

Functionality: The holes drilled in a PCB must be accurately placed and sized to ensure proper electrical connections between components and layers. If the holes are misaligned or the wrong size, it can lead to short circuits, open circuits, or other functional issues.

-

Reliability: Poorly drilled holes can cause mechanical stress on the PCB and its components, leading to failures over time. Precise drilling ensures that the holes are clean, burr-free, and properly sized to minimize stress and improve reliability.

-

Cost: Imprecise drilling can lead to a higher rate of defects and scrap, which increases the overall cost of PCB fabrication. By improving drilling precision, manufacturers can reduce waste and improve yields, ultimately lowering production costs.

Factors Affecting PCB Drilling Precision

Several factors can impact the precision of PCB drilling:

-

Drill Bit Quality: The quality of the drill bits used can greatly affect the precision of the holes. High-quality carbide or diamond drill bits are recommended for precise drilling.

-

Spindle Speed: The speed at which the drill bit rotates, known as the spindle speed, can impact hole quality. Higher spindle speeds can improve hole quality and reduce burring, but may also increase wear on the drill bit.

-

Feed Rate: The feed rate, or the speed at which the drill bit moves through the PCB, can also affect precision. Slower feed rates generally result in cleaner, more precise holes, but may increase production time.

-

Backing Material: The use of a backing material, such as aluminum or phenolic, can help to minimize burring and improve hole quality by supporting the PCB during drilling.

-

Drill File Optimization: The drill file, which contains the coordinates and sizes of all the holes to be drilled, must be optimized to ensure efficient and precise drilling. This includes minimizing tool changes, optimizing drill paths, and using appropriate drill sizes.

Techniques for Improving PCB Drilling Precision

There are several techniques that manufacturers can use to improve the precision of PCB drilling:

-

Peck Drilling: Peck drilling involves repeatedly withdrawing and reinserting the drill bit to clear chips and debris from the hole. This can help to improve hole quality and reduce burring, particularly for deeper holes.

-

Controlled Depth Drilling: Controlled depth drilling involves using a depth-controlled drill bit to ensure consistent hole depths across the PCB. This is particularly important for multilayer boards, where precise hole depths are critical for proper layer interconnections.

-

Laser Drilling: Laser drilling uses a high-powered laser to vaporize the PCB material, creating precise, small-diameter holes. This technique is particularly useful for high-density boards with very small features.

-

Plasma Drilling: Plasma drilling uses a high-temperature plasma arc to melt and vaporize the PCB material, creating clean, precise holes. This technique is often used for drilling through thick, multilayer boards.

-

Optimization Software: Many manufacturers use specialized software to optimize the drilling process, including drill file optimization, tool management, and machine setup. These software tools can help to improve efficiency, reduce errors, and enhance overall precision.

Impact of Precise PCB Drilling on Fabrication Costs

Precise PCB drilling can have a significant impact on the overall cost of PCB fabrication:

-

Reduced Scrap and Rework: By improving drilling precision, manufacturers can reduce the number of defective boards and minimize the need for rework. This can lead to significant cost savings by reducing material waste and labor costs.

-

Improved Yield: Precise drilling can also improve the overall yield of the PCB fabrication process, meaning that a higher percentage of the produced boards meet quality standards. This can help to lower the per-unit cost of production.

-

Faster Production Times: Optimized drilling processes, such as those using peck drilling or controlled depth drilling, can help to reduce drilling cycle times and improve overall production efficiency. This can lead to faster turnaround times and lower labor costs.

-

Reduced Tool Wear: High-quality drill bits and optimized drilling parameters can help to reduce wear on the drilling tools, extending their lifespan and reducing replacement costs.

-

Minimized Post-Processing: Precise drilling can minimize the need for post-processing steps, such as deburring or hole cleaning, which can add time and cost to the fabrication process.

Hole Size and Costs

The relationship between hole size and cost for a standard double sided PCB is outlined in the table below:

| Hole Size (mm) | Cost Impact |

|---|---|

| 0.2 – 0.5 | Low |

| 0.5 – 0.8 | Medium |

| 0.8 – 1.0 | High |

| > 1.0 | Very high |

As the hole size decreases, the cost impact increases due to the need for specialized drill bits and more precise drilling techniques. Therefore, designers should aim to use the largest acceptable hole size for their application to minimize costs.

FAQ

What is the smallest hole size that can be drilled in a PCB?

The smallest hole size that can be drilled in a PCB depends on the drilling technique used and the capabilities of the manufacturing equipment. Using advanced techniques like laser drilling, holes as small as 0.1mm in diameter can be achieved. However, for most standard PCB fabrication processes, the smallest practical hole size is around 0.2mm.

How does the number of layers in a PCB affect drilling cost?

The number of layers in a PCB can significantly affect drilling cost, as each additional layer requires more drilling time and increases the complexity of the drilling process. Multilayer boards may also require specialized drilling techniques, such as controlled depth drilling, to ensure proper layer interconnections. As a result, the cost of drilling for multilayer boards is generally higher than for single or double-layer boards.

What is the difference between mechanical drilling and laser drilling?

Mechanical drilling uses physical drill bits to remove material and create holes in the PCB, while laser drilling uses a high-powered laser to vaporize the material. Laser drilling is generally more precise and can create smaller holes than mechanical drilling, but it is also more expensive and may not be suitable for all materials. Mechanical drilling is the most common method for PCB fabrication due to its versatility and lower cost.

How often should drill bits be replaced to ensure precise drilling?

The frequency of drill bit replacement depends on several factors, including the material being drilled, the spindle speed, and the feed rate. In general, drill bits should be replaced when they become worn or damaged, as this can affect the precision and quality of the drilled holes. Manufacturers typically monitor drill bit wear and replace them according to established schedules or when defects are detected in the drilled holes.

Can precise drilling completely eliminate the need for post-processing steps?

While precise drilling can significantly reduce the need for post-processing steps like deburring or hole cleaning, it may not completely eliminate them in all cases. Some materials or hole geometries may still require additional processing to ensure proper functionality and reliability. However, by optimizing the drilling process and using advanced techniques, manufacturers can minimize the need for post-processing and the associated costs.

Conclusion

Precise PCB drilling is a critical aspect of the PCB fabrication process, as it directly impacts the functionality, reliability, and cost of the final product. By understanding the factors that affect drilling precision and implementing techniques to improve it, manufacturers can reduce scrap, improve yields, and lower overall production costs.

Designers can also play a role in reducing drilling costs by selecting appropriate hole sizes and minimizing the number of layers in their designs. By collaborating with manufacturers and optimizing designs for manufacturability, designers can help to ensure that their PCBs are produced efficiently and cost-effectively.

As PCB technology continues to advance, with increasing miniaturization and complexity, the importance of precise drilling will only continue to grow. Manufacturers that invest in advanced drilling technologies and processes will be well-positioned to meet the evolving demands of the industry and deliver high-quality, cost-effective PCBs to their customers.

Leave a Reply