What is BGA Assembly?

BGA (Ball Grid Array) assembly is a process of attaching a BGA component to a printed circuit board (PCB) using a specialized soldering technique. BGA components have a grid of solder balls on their underside, which are used to make electrical connections with the corresponding pads on the PCB. This type of assembly is commonly used for high-density components, such as microprocessors, FPGAs, and ASICs, due to its ability to provide a large number of interconnections in a small footprint.

Advantages of BGA Assembly

BGA assembly offers several advantages over other types of component packaging and assembly methods:

-

High interconnection density: BGA packages can accommodate a large number of interconnections in a small area, making them ideal for complex, high-performance electronic devices.

-

Improved electrical performance: The short interconnection lengths in BGA packages reduce inductance and capacitance, resulting in better signal integrity and faster signal propagation.

-

Enhanced thermal performance: The large number of solder balls in a BGA package provides a efficient thermal path for dissipating heat from the component to the PCB.

-

Reduced package size: BGA packages are typically smaller than other types of packages with equivalent pin counts, allowing for more compact PCB designs.

-

Increased reliability: When properly assembled, BGA connections are highly reliable and resistant to mechanical stress and thermal cycling.

BGA Assembly Process

The BGA assembly process involves several key steps to ensure a reliable and high-quality connection between the component and the PCB.

1. PCB Preparation

Before the BGA component can be attached, the PCB must be properly prepared. This involves:

- Cleaning the PCB to remove any contaminants or debris

- Applying solder paste to the BGA pads using a stencil or screen printing process

- Inspecting the solder paste application to ensure proper coverage and uniformity

2. Component Placement

Once the PCB is prepared, the BGA component is placed onto the board using a pick-and-place machine or by hand, depending on the volume and complexity of the assembly. The component is aligned with the solder paste-covered pads on the PCB, and a small amount of pressure is applied to ensure proper contact.

3. Reflow Soldering

After the component is placed, the PCB is heated in a reflow oven to melt the solder paste and form a permanent connection between the component and the board. The reflow process typically involves a carefully controlled temperature profile that gradually heats the assembly to the melting point of the solder, holds it at that temperature for a specific duration, and then cools it down to room temperature.

4. Inspection and Testing

Following the reflow process, the assembled PCB undergoes visual inspection and electrical testing to verify the quality and functionality of the BGA connections. This may involve:

- X-ray inspection to check for voids, bridging, or other defects in the solder joints

- Automated optical inspection (AOI) to verify component placement and solder joint formation

- In-circuit testing (ICT) or functional testing to ensure proper electrical performance of the assembled board

Challenges in BGA Assembly

While BGA assembly offers many benefits, it also presents some unique challenges that must be addressed to ensure reliable and high-quality results.

Thermal Management

One of the primary challenges in BGA assembly is managing the heat generated by the component during operation. The high interconnection density of BGA packages can make it difficult to dissipate heat effectively, leading to increased component temperatures and potential reliability issues. To mitigate this, designers must carefully consider the thermal characteristics of the BGA package, the PCB layout, and the cooling solution employed in the final product.

Rework and Repair

Another challenge associated with BGA assembly is the difficulty of reworking or repairing faulty connections. Due to the small size and close spacing of the solder balls, it can be challenging to remove and replace a BGA component without damaging the PCB or adjacent components. Specialized equipment and techniques, such as hot air rework stations and reballing processes, are often required to perform successful BGA Rework.

Process Control

Achieving consistent and reliable BGA assembly results requires strict control over the entire assembly process, from PCB preparation to final inspection. This includes maintaining proper solder paste application, component placement accuracy, reflow temperature profiles, and cleanliness throughout the process. Even small variations in these parameters can lead to defects or failures in the final assembly.

BGA Assembly Equipment and Tools

To successfully perform BGA assembly, manufacturers rely on a range of specialized equipment and tools designed to address the unique challenges of this process.

Stencil Printers

Stencil printers are used to apply solder paste to the PCB pads prior to component placement. These machines use a laser-cut stencil or screen to deposit a precise amount of solder paste onto the board, ensuring consistent coverage and thickness across all the pads.

Pick-and-Place Machines

Pick-and-place machines are automated systems that place components, including BGA packages, onto the PCB with high speed and accuracy. These machines use computer vision and precision mechanics to pick up components from feeders or trays and place them onto the solder paste-covered pads on the board.

Reflow Ovens

Reflow ovens are used to melt the solder paste and form permanent connections between the components and the PCB. These ovens typically employ a multi-zone heating system that allows for precise control over the temperature profile during the reflow process, ensuring optimal solder joint formation and minimizing the risk of thermal damage to the components or board.

Inspection Equipment

To verify the quality of BGA assemblies, manufacturers use a variety of inspection equipment, such as:

- X-ray machines for non-destructive inspection of solder joint formation and internal structure

- Automated optical inspection (AOI) systems for verifying component placement and solder joint appearance

- In-circuit test (ICT) systems for electrical testing of the assembled board

Rework Stations

When defects or failures are identified in a BGA assembly, rework stations are used to remove and replace the faulty component. These stations typically include hot air systems for heating the component and solder joints, as well as specialized tools for handling and aligning the component during the rework process.

BGA Assembly Services

Many electronics manufacturers offer BGA assembly services to help customers integrate BGA components into their products. These services can range from simple PCB Assembly to full turnkey solutions that include design, prototyping, and production.

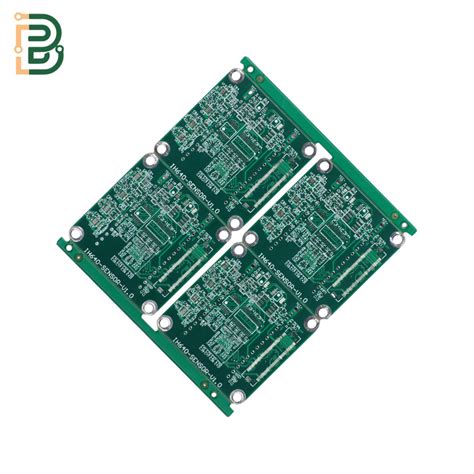

PCB Assembly Services

PCB assembly services typically include the following steps:

-

PCB fabrication: The PCB is manufactured according to the customer’s design specifications, including the layout, material selection, and surface finish.

-

Solder paste application: Solder paste is applied to the BGA pads on the PCB using a stencil or screen printing process.

-

Component placement: The BGA component, along with any other components specified in the design, are placed onto the PCB using pick-and-place machines or by hand.

-

Reflow soldering: The assembled PCB is heated in a reflow oven to melt the solder paste and form permanent connections between the components and the board.

-

Inspection and testing: The assembled PCB undergoes visual inspection and electrical testing to verify the quality and functionality of the BGA connections and overall assembly.

Turnkey Solutions

In addition to basic PCB assembly services, some manufacturers offer full turnkey solutions that encompass the entire product development process, including:

- Product design and engineering

- Prototyping and testing

- Component sourcing and procurement

- PCB fabrication and assembly

- Box build and final product assembly

- Quality control and testing

- Packaging and shipping

These turnkey solutions provide customers with a single point of contact for their entire project, simplifying the development process and reducing time-to-market.

Choosing a BGA Assembly Service Provider

When selecting a BGA assembly service provider, there are several key factors to consider to ensure the best possible results for your project.

Experience and Expertise

Look for a service provider with extensive experience in BGA assembly and a proven track record of success. They should have a deep understanding of the challenges associated with BGA assembly and the expertise necessary to overcome them.

Equipment and Capabilities

Ensure that the service provider has the necessary equipment and capabilities to handle your specific BGA assembly requirements. This includes stencil printers, pick-and-place machines, reflow ovens, and inspection equipment that are properly maintained and calibrated.

Quality Control and Certifications

Choose a service provider that has robust quality control processes in place and holds relevant industry certifications, such as ISO 9001, IPC-A-610, and J-STD-001. These certifications demonstrate the provider’s commitment to quality and adherence to industry standards.

Communication and Support

Effective communication and support are critical to the success of any BGA assembly project. Look for a service provider that is responsive, proactive, and willing to work closely with you to understand your requirements and provide timely updates throughout the project.

Cost and Lead Time

While cost and lead time are important considerations, they should not be the sole deciding factors when choosing a BGA assembly service provider. Prioritize quality, reliability, and expertise over low costs or fast turnaround times, as the long-term benefits of a well-executed assembly will outweigh any short-term savings.

Conclusion

BGA assembly is a critical process for integrating high-density components into modern electronic devices. By understanding the challenges, equipment, and best practices associated with BGA assembly, manufacturers can ensure reliable and high-quality results for their products. When selecting a BGA assembly service provider, it is essential to consider factors such as experience, capabilities, quality control, communication, and cost to find the best fit for your project requirements.

Frequently Asked Questions (FAQ)

-

What is the difference between BGA and other surface mount technologies?

BGA (Ball Grid Array) differs from other surface mount technologies, such as QFP (Quad Flat Pack) and SMD (Surface Mount Device), in that it uses a grid of solder balls on the underside of the component to make electrical connections with the PCB. This allows for a higher density of interconnections in a smaller footprint compared to other package types. -

Can BGA components be reworked or repaired?

Yes, BGA components can be reworked or repaired, but the process is more challenging than with other types of components due to the small size and close spacing of the solder balls. Specialized equipment, such as hot air rework stations and reballing tools, are typically required to perform successful BGA rework. -

What are the most common defects in BGA assembly?

Some of the most common defects in BGA assembly include: - Solder joint voids: Gaps or air pockets within the solder joint that can reduce electrical and thermal performance

- Bridging: Unintended connections between adjacent solder balls or pads

- Misalignment: Improper placement of the BGA component on the PCB

-

Head-in-pillow: A condition where the solder ball on the component does not fully collapse and bond with the solder paste on the PCB

-

How can I ensure the quality of my BGA assembly?

To ensure the quality of your BGA assembly, consider the following: - Work with an experienced and qualified BGA assembly service provider

- Use high-quality components, PCBs, and solder paste

- Implement strict process controls and monitor key parameters, such as solder paste application, component placement, and reflow temperature profiles

-

Perform thorough inspection and testing, including X-ray, AOI, and electrical testing, to verify the quality of the final assembly

-

What should I look for when selecting a BGA assembly service provider?

When selecting a BGA assembly service provider, look for: - Experience and expertise in BGA assembly

- Proper equipment and capabilities to handle your specific requirements

- Robust quality control processes and relevant industry certifications

- Effective communication and support throughout the project

- Competitive cost and lead time, balanced with a focus on quality and reliability

Leave a Reply