What is RoHS Compliance?

RoHS, or the Restriction of Hazardous Substances, is a directive that originated in the European Union (EU) to restrict the use of certain hazardous substances in electrical and electronic equipment. The primary goal of RoHS is to minimize the environmental impact and protect human health by reducing the use of toxic materials in the manufacturing process.

The six restricted substances under RoHS are:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent Chromium (Cr6+)

- Polybrominated Biphenyls (PBB)

- Polybrominated Diphenyl Ethers (PBDE)

To be RoHS compliant, a product must not contain any of these substances above the maximum concentration values (MCVs) set by the directive.

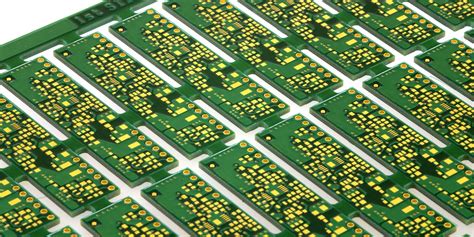

The Importance of RoHS Compliance in PCB assemblies

PCB assemblies are the backbone of electronic devices, and ensuring their RoHS compliance is crucial for several reasons:

1. Environmental Protection

By adhering to RoHS standards, we minimize the release of hazardous substances into the environment during the manufacturing, use, and disposal of electronic devices. This helps reduce pollution and conserve natural resources for future generations.

2. Human Health and Safety

Exposure to the restricted substances can have severe health consequences, such as neurological disorders, cancer, and reproductive issues. By eliminating these substances from our PCB assemblies, we prioritize the health and safety of our employees, customers, and end-users.

3. Legal Compliance

RoHS compliance is a legal requirement for electronic products sold in the EU and many other countries worldwide. By ensuring our PCB assemblies meet these standards, we help our clients avoid legal issues and maintain access to global markets.

4. Competitive Advantage

As consumers become increasingly aware of the environmental impact of electronic devices, the demand for RoHS-compliant products continues to grow. By offering RoHS-compliant PCB assemblies, we provide our clients with a competitive edge in the market and help them meet the evolving needs of their customers.

Our Commitment to RoHS Compliance

At our company, we are dedicated to providing our clients with high-quality, RoHS-compliant PCB assemblies and prototypes. To achieve this, we have implemented a comprehensive RoHS compliance program that encompasses every aspect of our manufacturing process.

1. Material Selection

We work closely with our suppliers to ensure that all components and materials used in our PCB assemblies are RoHS compliant. Our team thoroughly reviews material declarations and conducts regular audits to verify compliance.

2. Manufacturing Processes

Our state-of-the-art manufacturing facilities are designed to minimize the risk of contamination from restricted substances. We employ strict process controls, regular equipment maintenance, and employee training to ensure consistent RoHS compliance throughout the production process.

3. Testing and Verification

To guarantee the RoHS compliance of our PCB assemblies, we conduct rigorous testing and verification procedures. This includes X-ray fluorescence (XRF) screening, which allows us to detect the presence of restricted substances in components and finished assemblies.

4. Documentation and Traceability

We maintain detailed documentation of our RoHS compliance efforts, including material declarations, test results, and process records. This ensures full traceability and enables us to provide our clients with the necessary evidence of compliance.

RoHS Compliant PCB Assembly Services

Our company offers a comprehensive range of RoHS-compliant PCB assembly services to meet the diverse needs of our clients. These services include:

1. Prototype PCB Assembly

We specialize in quick-turn prototype PCB assembly, allowing our clients to test and refine their designs while ensuring RoHS compliance from the early stages of product development. Our experienced team can handle various prototype requirements, from simple to complex designs.

2. Low-Volume Production

For clients requiring low-volume production runs, we offer flexible and cost-effective RoHS-compliant PCB assembly services. Our agile manufacturing processes enable us to efficiently produce high-quality, compliant assemblies in smaller quantities.

3. High-Volume Production

As our clients’ products move into mass production, we scale our RoHS-compliant PCB assembly services to meet their high-volume requirements. Our automated assembly lines and strict quality control measures ensure consistent RoHS compliance and reliability across large production runs.

4. Box Build and System Integration

In addition to PCB assembly, we offer RoHS-compliant box build and system integration services. Our team can assemble complete electronic devices, including enclosures, wiring, and testing, while maintaining RoHS compliance throughout the process.

Benefits of Choosing Our RoHS Compliant PCB Assembly Services

By partnering with us for your RoHS-compliant PCB assembly needs, you can enjoy several benefits:

- Peace of mind knowing that your products meet the strict RoHS standards

- Access to our expertise in RoHS compliance and PCB assembly best practices

- Faster time-to-market with our efficient and reliable assembly services

- Cost savings through our optimized manufacturing processes and economies of scale

- Enhanced brand reputation by demonstrating your commitment to environmental sustainability and consumer safety

Frequently Asked Questions (FAQ)

1. What is the difference between RoHS and REACH?

While both RoHS and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are EU directives aimed at reducing the use of hazardous substances, they have different scopes. RoHS specifically targets electrical and electronic equipment, while REACH applies to all chemicals used in various industries.

2. Can you provide RoHS compliance documentation for my PCB assemblies?

Yes, we can provide detailed RoHS compliance documentation for your PCB assemblies, including material declarations, test results, and process records. This documentation can be used to demonstrate compliance to your customers and regulatory authorities.

3. Do you offer Lead-Free PCB assembly?

Yes, we offer lead-free PCB assembly as part of our RoHS compliance services. Lead-free assembly uses alternative solder alloys that do not contain lead, such as tin-silver-copper (SAC) alloys.

4. How do you ensure the RoHS compliance of your suppliers?

We have a rigorous supplier management program that includes regular audits, material declarations, and testing to ensure the RoHS compliance of our suppliers. We only work with suppliers who can consistently demonstrate their commitment to RoHS compliance.

5. Can you help me design an RoHS-compliant PCB?

Yes, our experienced design team can assist you in designing an RoHS-compliant PCB. We can provide guidance on material selection, component placement, and manufacturing processes to ensure your design meets RoHS requirements while optimizing performance and reliability.

Conclusion

In conclusion, RoHS compliance is a critical aspect of PCB assembly in today’s electronic industry. At our company, we are committed to providing our clients with high-quality, RoHS-compliant PCB assemblies and prototypes. Through our comprehensive compliance program, expertise in PCB assembly, and dedication to customer satisfaction, we help our clients navigate the complexities of RoHS compliance and bring their products to market with confidence.

By choosing our RoHS-compliant PCB assembly services, you can trust that your products will meet the strict environmental and safety standards set by the RoHS directive. Whether you need prototype, low-volume, or high-volume production, our team is ready to support you every step of the way.

Don’t compromise on the quality and compliance of your PCB assemblies. Partner with us today and experience the benefits of working with a leading provider of RoHS-compliant PCB assembly services.

Leave a Reply