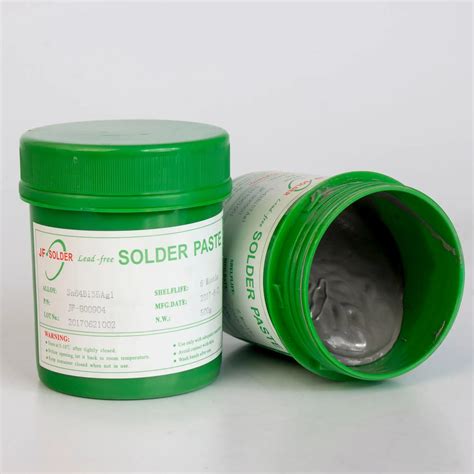

What is Solder Paste?

Solder paste is a mixture of tiny solder particles suspended in a flux medium. It is a grey, paste-like material that is applied to the PCB pads before the components are placed. The solder particles are typically made of a tin-lead (SnPb) alloy or lead-free alternatives such as tin-silver-copper (SAC) alloys. The flux medium serves to remove oxides from the metal surfaces, prevent oxidation during the soldering process, and promote the formation of a strong solder joint.

Composition of Solder Paste

The composition of solder paste can vary depending on the specific application and requirements. However, a typical solder paste consists of the following components:

| Component | Percentage |

|---|---|

| Solder Alloy | 80-90% |

| Flux | 10-20% |

| Additives | 0-1% |

The solder alloy is the main component of the solder paste and determines its melting temperature, strength, and reliability. The flux is responsible for cleaning the metal surfaces and protecting them from oxidation. Additives such as thickeners and tackifiers may be added to improve the rheological properties of the solder paste.

The Role of Solder Paste in SMT Assembly

Solder paste plays a crucial role in the SMT assembly process. It serves multiple purposes, including:

1. Forming Electrical and Mechanical Connections

The primary function of solder paste is to form electrical and mechanical connections between the components and the PCB pads. When the solder paste is heated during the reflow soldering process, the solder particles melt and form a metallurgical bond with the component leads and PCB pads. This bond ensures reliable electrical conductivity and provides mechanical strength to hold the components in place.

2. Providing Temporary Adhesion

Before the reflow soldering process, the solder paste acts as a temporary adhesive to hold the components in place on the PCB. This is crucial for maintaining the correct positioning of the components during the assembly process. The tackiness of the solder paste prevents the components from moving or falling off the PCB before the soldering process is completed.

3. Enabling Precise Component Placement

The solder paste is applied to the PCB pads using a stencil printing process. The stencil is a thin metal sheet with openings that correspond to the PCB pads. The solder paste is pushed through the openings onto the pads, creating a precise and uniform deposit. This precise application of solder paste enables accurate placement of the components on the PCB, ensuring proper alignment and spacing.

4. Facilitating Uniform Heating

During the reflow soldering process, the PCB and components are heated to a specific temperature profile. The solder paste plays a role in facilitating uniform heating across the PCB. The flux in the solder paste helps to distribute the heat evenly, preventing localized overheating or cold spots. This uniform heating is essential for achieving reliable solder joints and preventing defects such as bridging or tombstoning.

Solder Paste Application Methods

There are several methods for applying solder paste to the PCB pads. The most common methods are:

1. Stencil Printing

Stencil printing is the most widely used method for applying solder paste in SMT assembly. A stencil is placed over the PCB, and the solder paste is pushed through the openings onto the pads using a squeegee. This method provides a precise and uniform deposit of solder paste, making it suitable for high-volume production.

2. Dispensing

Dispensing involves using a pneumatic or mechanical dispenser to apply solder paste directly onto the PCB pads. This method is typically used for low-volume production or for applying solder paste to specific areas that are difficult to reach with a stencil. Dispensing offers flexibility but may not provide the same level of precision and uniformity as stencil printing.

3. Jet Printing

Jet printing is a newer technology that uses a printhead to deposit solder paste onto the PCB pads. It works similarly to an inkjet printer, with the solder paste being ejected through small nozzles. Jet printing offers high precision and the ability to apply solder paste to specific areas without the need for a stencil. However, it may have limitations in terms of production speed compared to stencil printing.

Solder Paste Inspection

After the solder paste is applied to the PCB pads, it is important to inspect the deposit to ensure its quality and consistency. Solder paste inspection (SPI) is a critical step in the SMT assembly process. It involves using automated optical inspection (AOI) systems to analyze the solder paste deposit for defects such as insufficient volume, bridging, or misalignment.

SPI systems use advanced imaging techniques and algorithms to measure the volume, height, and area of the solder paste deposit. They compare these measurements to predefined criteria to determine if the deposit meets the required specifications. If any defects are detected, the PCB can be flagged for rework or repair before the components are placed.

| Defect Type | Description |

|---|---|

| Insufficient Volume | The solder paste deposit is too small, resulting in weak solder joints |

| Excessive Volume | The solder paste deposit is too large, causing bridging or short circuits |

| Misalignment | The solder paste deposit is not aligned with the PCB pad |

| Bridging | The solder paste deposits on adjacent pads are connected, causing short circuits |

By performing SPI, manufacturers can identify and correct solder paste defects early in the assembly process, reducing the risk of defects in the final product.

Solder Paste Storage and Handling

Solder paste is a perishable material that requires proper storage and handling to maintain its quality and performance. The following guidelines should be followed when storing and handling solder paste:

Storage Temperature

Solder paste should be stored at a controlled temperature, typically between 0°C and 10°C (32°F and 50°F). Storing solder paste at higher temperatures can cause the solder particles to oxidize and the flux to degrade, affecting the soldering performance.

Shelf Life

Solder paste has a limited shelf life, typically ranging from 3 to 6 months when stored at the recommended temperature. It is important to use the solder paste within its shelf life to ensure optimal performance. Expired solder paste may have reduced solderability and may not form reliable solder joints.

Handling Precautions

When handling solder paste, it is important to follow proper procedures to prevent contamination and ensure consistent quality. Some key handling precautions include:

- Wearing gloves to prevent skin contact and contamination

- Using clean, lint-free cloths or wipes for cleaning

- Avoiding exposure to excessive heat or humidity

- Stirring the solder paste gently before use to ensure homogeneity

- Keeping the solder paste container closed when not in use to prevent drying and contamination

Conclusion

Solder paste is a critical component in the PCB SMT assembly process. It plays a significant role in forming reliable electrical and mechanical connections between components and the PCB. The quality and consistency of the solder paste directly impact the reliability and functionality of the final electronic device.

By understanding the composition, application methods, inspection techniques, and handling requirements of solder paste, manufacturers can optimize their SMT assembly process and produce high-quality electronic products. As technology advances and miniaturization continues, the importance of solder paste in enabling reliable and efficient PCB assembly will only continue to grow.

Frequently Asked Questions (FAQ)

-

What is the difference between leaded and lead-free solder paste?

Leaded solder paste contains a tin-lead alloy, typically with a composition of 63% tin and 37% lead (Sn63Pb37). Lead-free solder paste, on the other hand, uses alternative alloys such as tin-silver-copper (SAC) or tin-bismuth (SnBi) to comply with environmental regulations that restrict the use of lead in electronics. -

Can solder paste be reused?

No, solder paste should not be reused. Once the solder paste has been exposed to air and heated during the soldering process, its properties and performance can degrade. Reusing solder paste can lead to defects and reliability issues in the solder joints. -

What is the shelf life of solder paste?

The shelf life of solder paste typically ranges from 3 to 6 months when stored at the recommended temperature (0°C to 10°C or 32°F to 50°F). However, the actual shelf life may vary depending on the specific solder paste formulation and storage conditions. It is important to refer to the manufacturer’s guidelines and use the solder paste within its specified shelf life. -

How is solder paste viscosity measured?

Solder paste viscosity is typically measured using a rheometer or viscometer. These instruments measure the resistance of the solder paste to flow under applied stress. The viscosity is expressed in centipoise (cP) or pascal-seconds (Pa·s). Solder paste manufacturers provide viscosity specifications to ensure consistent printing and dispensing performance. -

What is the purpose of the flux in solder paste?

The flux in solder paste serves several purposes. It removes oxides and contaminants from the metal surfaces, promoting wetting and spreading of the molten solder. The flux also protects the metal surfaces from oxidation during the soldering process. Additionally, the flux helps to distribute heat evenly across the solder joint, facilitating uniform melting and solidification of the solder.

Leave a Reply