Introduction to PCB Simulation

PCB (Printed Circuit Board) simulation is a crucial step in the design and development of electronic devices. It allows engineers to test and validate the performance of their PCB Designs before the actual manufacturing process begins. PCB simulation can be divided into two main categories: pre-layout simulation and post-layout simulation.

What is Pre-Layout PCB Simulation?

Pre-layout PCB simulation is the process of simulating the behavior of a PCB design before the physical layout is created. This type of simulation is typically performed using schematic-level models of the components and interconnects. The goal of pre-layout simulation is to verify the functionality and performance of the circuit design, without considering the physical constraints of the PCB Layout.

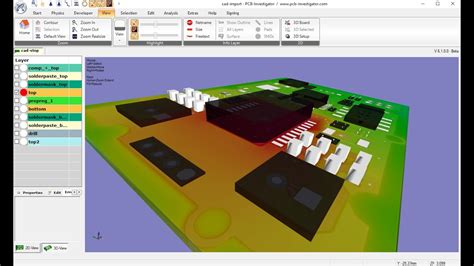

What is Post-Layout PCB Simulation?

Post-layout PCB simulation, on the other hand, is the process of simulating the behavior of a PCB design after the physical layout has been created. This type of simulation takes into account the actual physical properties of the PCB, such as the trace widths, lengths, and spacing, as well as the parasitics associated with the interconnects. The goal of post-layout simulation is to verify that the PCB design will perform as expected in the real world, considering the effects of the physical layout on signal integrity, power integrity, and electromagnetic compatibility (EMC).

Differences Between Pre-Layout and Post-Layout PCB Simulation

While both pre-layout and post-layout simulations are important for ensuring the success of a PCB design, there are several key differences between the two types of simulations.

Level of Detail

One of the main differences between pre-layout and post-layout simulations is the level of detail that is considered. Pre-layout simulations are typically performed using simplified models of the components and interconnects, which do not take into account the physical properties of the PCB layout. This allows for faster simulation times and easier debugging of the circuit design.

Post-layout simulations, on the other hand, use more detailed models that include the physical properties of the PCB layout. This allows for more accurate predictions of the circuit’s behavior, but also requires more computational resources and longer simulation times.

Accuracy

Another key difference between pre-layout and post-layout simulations is the level of accuracy that can be achieved. Pre-layout simulations are generally less accurate than post-layout simulations, because they do not take into account the effects of the physical layout on the circuit’s performance.

Post-layout simulations, on the other hand, can provide much more accurate predictions of the circuit’s behavior, because they consider the actual physical properties of the PCB. This is especially important for high-speed designs, where signal integrity and power integrity are critical.

Simulation Time

The simulation time required for pre-layout and post-layout simulations can also vary significantly. Pre-layout simulations are generally faster than post-layout simulations, because they use simplified models and do not require the computation of complex physical effects.

Post-layout simulations, on the other hand, can take much longer to run, because they require more detailed models and more complex computations. This can be a significant challenge for large or complex PCB designs, where simulation times can become prohibitively long.

Design Iteration

Finally, the design iteration process is another important difference between pre-layout and post-layout simulations. Pre-layout simulations are typically performed early in the design process, before the physical layout has been created. This allows designers to quickly test and validate different circuit designs, and make changes as needed to optimize performance.

Post-layout simulations, on the other hand, are typically performed later in the design process, after the physical layout has been created. This means that any changes to the circuit design at this stage will require modifications to the physical layout, which can be time-consuming and expensive.

Importance of Both Pre-Layout and Post-Layout PCB Simulations

Despite the differences between pre-layout and post-layout simulations, both types of simulations are important for ensuring the success of a PCB design.

Pre-Layout Simulation Benefits

Pre-layout simulations are important for several reasons. First, they allow designers to quickly test and validate different circuit designs, without the need for physical prototypes. This can save significant time and cost in the design process, by allowing designers to identify and fix problems early on.

Second, pre-layout simulations can help designers optimize the performance of their circuits, by allowing them to test different component values and configurations. This can be especially important for analog circuits, where small changes in component values can have a significant impact on performance.

Post-Layout Simulation Benefits

Post-layout simulations are also important for several reasons. First, they provide the most accurate predictions of a circuit’s behavior, because they take into account the actual physical properties of the PCB. This is especially important for high-speed designs, where signal integrity and power integrity are critical.

Second, post-layout simulations can help designers identify and fix problems that may not be apparent in pre-layout simulations. For example, post-layout simulations can reveal issues with signal reflection, crosstalk, and electromagnetic interference (EMI), which may not be visible in pre-layout simulations.

Finally, post-layout simulations can help designers optimize the physical layout of their PCB, by allowing them to test different trace widths, spacings, and routing strategies. This can help to minimize signal integrity issues and improve overall performance.

FAQ

1. What is the main difference between pre-layout and post-layout PCB simulation?

The main difference between pre-layout and post-layout PCB simulation is the level of detail that is considered. Pre-layout simulations use simplified models of the components and interconnects, while post-layout simulations use more detailed models that include the physical properties of the PCB layout.

2. Which type of simulation is more accurate, pre-layout or post-layout?

Post-layout simulations are generally more accurate than pre-layout simulations, because they take into account the actual physical properties of the PCB. This is especially important for high-speed designs, where signal integrity and power integrity are critical.

3. Which type of simulation is faster, pre-layout or post-layout?

Pre-layout simulations are generally faster than post-layout simulations, because they use simplified models and do not require the computation of complex physical effects.

4. When should pre-layout simulations be performed in the design process?

Pre-layout simulations are typically performed early in the design process, before the physical layout has been created. This allows designers to quickly test and validate different circuit designs, and make changes as needed to optimize performance.

5. When should post-layout simulations be performed in the design process?

Post-layout simulations are typically performed later in the design process, after the physical layout has been created. This allows designers to verify that the PCB design will perform as expected in the real world, considering the effects of the physical layout on signal integrity, power integrity, and EMC.

Conclusion

In conclusion, both pre-layout and post-layout PCB simulations are important for ensuring the success of a PCB design. Pre-layout simulations allow designers to quickly test and validate different circuit designs, while post-layout simulations provide the most accurate predictions of a circuit’s behavior, taking into account the actual physical properties of the PCB.

By using both types of simulations in the design process, engineers can identify and fix problems early on, optimize performance, and ensure that their PCB designs will perform as expected in the real world. As PCB designs become more complex and high-speed, the importance of accurate and efficient simulation tools will only continue to grow.

Leave a Reply