The Role of PCB Layout in EV Charging Stations

PCB layout plays a crucial role in the design and functionality of EV charging stations. A well-designed PCB ensures optimal performance, reliability, and safety of the charging system. Here are some key aspects of PCB layout that contribute to the efficiency of EV charging stations:

Proper Component Placement

The placement of components on the PCB is a critical factor in the overall performance of the charging station. The layout should be designed to minimize the distance between components, reduce signal interference, and ensure proper heat dissipation. This is particularly important for high-power components such as transformers, rectifiers, and power MOSFETs.

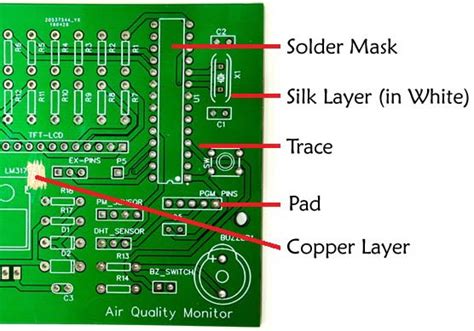

Adequate Trace Widths and Spacing

The trace widths and spacing on the PCB must be carefully calculated to handle the high currents required for EV charging. Insufficient trace widths can lead to excessive heat generation and potential failures, while inadequate spacing can result in signal crosstalk and electromagnetic interference (EMI). Proper trace design ensures the reliable and efficient transfer of power from the charging station to the EV battery.

Effective Shielding and Grounding

EV charging stations operate in environments with potential electromagnetic interference (EMI) sources, such as other electronic devices and power lines. Effective shielding and grounding techniques are essential to minimize the impact of EMI on the charging system. This includes the use of ground planes, shielded connectors, and proper grounding of sensitive components.

Thermal Management

The high power levels involved in EV charging generate significant heat, which must be effectively managed to prevent component damage and ensure long-term reliability. PCB layout plays a crucial role in thermal management by incorporating features such as thermal vias, heat sinks, and strategically placed components to promote efficient heat dissipation.

The Importance of PCB Assembly in EV Charging Stations

While PCB layout sets the foundation for a reliable and efficient EV charging station, the quality of PCB assembly is equally important. Proper assembly ensures that the designed functionality is realized and the charging station performs as intended. Here are some key aspects of PCB assembly that contribute to the reliability of EV charging stations:

Component Selection and Sourcing

The selection of high-quality components is essential for the long-term reliability of EV charging stations. Components must be sourced from reputable suppliers and meet the required specifications for voltage, current, and temperature ratings. Counterfeit or substandard components can lead to premature failures and compromise the safety of the charging system.

Soldering Techniques

The soldering process is critical to the integrity of the PCB assembly. Proper soldering techniques, such as the use of lead-free solder, controlled soldering temperatures, and appropriate cleaning methods, ensure reliable electrical connections and prevent issues like cold solder joints or bridging. Automated soldering processes, such as wave soldering or selective soldering, can improve the consistency and quality of the assembly.

Inspection and Testing

Thorough inspection and testing of the assembled PCB are essential to identify any manufacturing defects or assembly errors. This includes visual inspection, automated optical inspection (AOI), and electrical testing. Rigorous testing procedures, such as high-voltage withstand tests and functional tests, ensure that the charging station meets the required safety standards and performs as intended.

Conformal Coating and Encapsulation

EV charging stations are often exposed to harsh environmental conditions, such as moisture, dust, and extreme temperatures. Conformal coating and encapsulation techniques protect the PCB assembly from these environmental factors, enhancing the durability and reliability of the charging station. These protective layers also provide additional insulation and prevent short circuits or electrical leakage.

The Benefits of Optimized PCB Layout and Assembly in EV Charging Stations

By adopting optimized PCB layout and assembly practices, EV charging station manufacturers can realize several benefits:

-

Improved Charging Efficiency: A well-designed PCB layout minimizes power losses and ensures efficient power transfer from the charging station to the EV battery. This translates to faster charging times and reduced energy consumption.

-

Enhanced Reliability: Proper component selection, soldering techniques, and protective measures like conformal coating contribute to the long-term reliability of the charging station. This reduces the frequency of failures and minimizes downtime for EV owners.

-

Reduced Maintenance Costs: By investing in quality PCB layout and assembly, EV charging station manufacturers can reduce the need for frequent repairs and maintenance. This leads to lower operational costs and improved customer satisfaction.

-

Compliance with Safety Standards: Adhering to best practices in PCB layout and assembly ensures that the charging station meets the necessary safety standards and regulations. This is crucial for the safe operation of EVs and the protection of users.

-

Scalability and Customization: Optimized PCB layout and assembly processes enable manufacturers to easily scale their production to meet the growing demand for EV charging stations. Additionally, customized PCB designs can be developed to cater to specific charging requirements or integrate additional features.

The Future of PCB trends in EV Charging Stations

As the EV market continues to evolve, PCB Trends in charging stations are expected to keep pace with the advancements in technology. Here are some emerging trends that are likely to shape the future of PCB design and assembly in EV charging stations:

Wireless Charging

Wireless charging technology is gaining traction in the EV industry, offering a convenient and cable-free charging experience. PCB layouts for wireless charging systems require special considerations for coil design, impedance matching, and electromagnetic compatibility (EMC). As wireless charging becomes more prevalent, PCB designers will need to adapt their layouts to accommodate this technology.

Smart Charging and IoT Integration

The integration of smart charging capabilities and Internet of Things (IoT) connectivity is becoming increasingly important in EV charging stations. PCB layouts will need to incorporate communication modules, sensors, and processing units to enable features like remote monitoring, energy management, and user authentication. This will require careful consideration of signal integrity, power management, and data security in the PCB design.

High-Power Charging

The demand for faster charging times is driving the development of high-power charging systems. PCB layouts for these systems will need to handle higher currents and voltages, requiring robust power electronics and advanced thermal management techniques. The use of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), may become more prevalent in high-power charging applications.

Modular and Scalable Designs

To accommodate the diverse charging needs of different EVs and charging locations, modular and scalable PCB designs will become increasingly important. These designs will allow for easy customization and expansion of charging capabilities, enabling manufacturers to adapt to the evolving market requirements.

Frequently Asked Questions (FAQ)

-

Q: What is the role of PCB layout in EV charging stations?

A: PCB layout plays a crucial role in ensuring the optimal performance, reliability, and safety of EV charging stations. It involves the proper placement of components, adequate trace widths and spacing, effective shielding and grounding, and thermal management techniques. -

Q: Why is PCB assembly important for EV charging stations?

A: PCB assembly is critical for realizing the designed functionality and ensuring the reliable performance of EV charging stations. It involves component selection and sourcing, proper soldering techniques, inspection and testing, and protective measures like conformal coating and encapsulation. -

Q: What are the benefits of optimized PCB layout and assembly in EV charging stations?

A: Optimized PCB layout and assembly offer several benefits, including improved charging efficiency, enhanced reliability, reduced maintenance costs, compliance with safety standards, and scalability and customization options. -

Q: What are some emerging trends in PCB design for EV charging stations?

A: Some emerging trends in PCB design for EV charging stations include wireless charging, smart charging and IoT integration, high-power charging, and modular and scalable designs. These trends are driven by advancements in technology and the evolving needs of the EV market. -

Q: How can manufacturers ensure the quality and reliability of PCB assembly in EV charging stations?

A: Manufacturers can ensure the quality and reliability of PCB assembly by selecting high-quality components from reputable suppliers, employing proper soldering techniques, conducting thorough inspection and testing, and applying protective measures like conformal coating and encapsulation.

Conclusion

PCB layout and PCB assembly are setting a new trend in the development of electric vehicle charging stations. The growing demand for efficient, reliable, and safe charging infrastructure has highlighted the importance of well-designed and properly assembled PCBs. By adopting best practices in PCB layout and assembly, manufacturers can improve charging efficiency, enhance reliability, reduce maintenance costs, and ensure compliance with safety standards.

As the EV market continues to evolve, PCB trends in charging stations are expected to keep pace with technological advancements. Wireless charging, smart charging and IoT integration, high-power charging, and modular and scalable designs are some of the emerging trends that will shape the future of PCB design and assembly in EV charging stations.

By staying at the forefront of these trends and investing in optimized PCB layout and assembly processes, manufacturers can position themselves to meet the growing demand for reliable and efficient EV charging infrastructure. This will not only support the widespread adoption of electric vehicles but also contribute to a more sustainable and environmentally friendly transportation ecosystem.

| PCB Layout Considerations | PCB Assembly Considerations |

|---|---|

| Proper Component Placement | Component Selection and Sourcing |

| Adequate Trace Widths and Spacing | Soldering Techniques |

| Effective Shielding and Grounding | Inspection and Testing |

| Thermal Management | Conformal Coating and Encapsulation |

Table 1: Key considerations for PCB layout and assembly in EV charging stations.

| Emerging PCB Trends | Description |

|---|---|

| Wireless Charging | Incorporation of wireless charging technology in PCB layouts |

| Smart Charging and IoT Integration | Integration of communication modules, sensors, and processing units for smart charging and IoT connectivity |

| High-Power Charging | Handling higher currents and voltages for faster charging times |

| Modular and Scalable Designs | Designs that allow for easy customization and expansion of charging capabilities |

Table 2: Emerging PCB trends in EV charging stations.

By embracing these PCB layout and assembly best practices and staying updated with the latest trends, manufacturers can develop EV charging stations that meet the evolving needs of the market and contribute to the sustainable growth of the electric vehicle industry.

Leave a Reply