Introduction to PCB Manufacturing and Additive Manufacturing

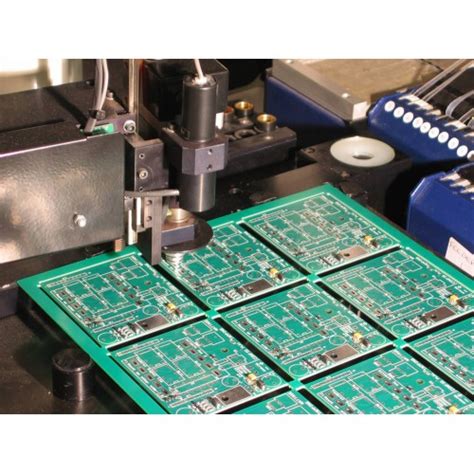

Printed Circuit Boards (PCBs) are the backbone of modern electronics, connecting and supporting various components to create functional devices. Traditional PCB manufacturing methods, such as subtractive manufacturing, have been the standard for decades. However, with the advent of additive manufacturing technologies, there is an opportunity to revolutionize PCB production, particularly for multilayer PCBs.

Additive manufacturing, also known as 3D printing, is a process that builds objects layer by layer using materials such as plastics, metals, or ceramics. This technology has already transformed various industries, from aerospace to healthcare, by enabling faster prototyping, reduced waste, and increased design flexibility. In the context of PCB manufacturing, additive manufacturing offers several advantages over traditional methods.

Benefits of Additive Manufacturing in PCB Production

- Rapid Prototyping: Additive manufacturing allows for quick and cost-effective prototyping of PCB designs, enabling faster iteration and optimization of layouts.

- Reduced Waste: Unlike subtractive manufacturing, which removes material to create the desired pattern, additive manufacturing only uses the necessary amount of material, resulting in reduced waste and environmental impact.

- Increased Design Flexibility: Additive manufacturing enables the creation of complex geometries and unique features that are difficult or impossible to achieve with traditional methods, allowing for more innovative PCB designs.

- Shorter Lead Times: By streamlining the manufacturing process and eliminating the need for multiple steps, additive manufacturing can significantly reduce lead times for PCB production.

Current State of Additive Manufacturing in PCB Industry

While additive manufacturing has been widely adopted in various industries, its application in PCB manufacturing is still in its early stages. Several companies and research institutions are actively exploring the potential of additive manufacturing for PCB production, with a focus on developing new materials, processes, and equipment.

Key Players in Additive PCB Manufacturing

| Company | Technology | Applications |

|---|---|---|

| Nano Dimension | DragonFly LDM | Multilayer PCBs, Antennas, RF Components |

| Optomec | Aerosol Jet | Printed Electronics, Sensors, Antennas |

| Voxel8 | Active Mixing | Embedded Electronics, 3D Printed Circuits |

| BotFactory | SV2 | Rapid PCB Prototyping, Education |

These companies are at the forefront of additive PCB manufacturing, developing innovative solutions to address the challenges and limitations of traditional manufacturing methods.

Challenges and Limitations of Additive PCB Manufacturing

Despite the potential benefits of additive manufacturing in PCB production, there are several challenges and limitations that need to be addressed before widespread adoption can occur.

Material Properties and Performance

One of the main challenges in additive PCB manufacturing is the development of materials that can match the performance and reliability of traditionally manufactured PCBs. Conductive inks and substrates used in additive manufacturing must exhibit excellent electrical properties, thermal stability, and mechanical strength to ensure the proper functioning of the final product.

Resolution and Feature Size

Additive manufacturing processes generally have lower resolution and larger minimum feature sizes compared to traditional PCB manufacturing methods. This limitation can impact the ability to create high-density interconnects and fine-pitch components, which are essential for modern electronics.

Process Scalability and Throughput

Additive manufacturing processes for PCBs are currently slower and less scalable than traditional methods, which can limit their adoption for high-volume production. Improving the speed and throughput of additive PCB manufacturing equipment is crucial for making the technology viable for mass production.

Standardization and Qualification

As with any new technology, additive PCB manufacturing lacks established standards and qualification processes. Developing industry-wide guidelines and certifications for additive PCB manufacturing is essential to ensure consistency, reliability, and acceptance by end-users.

Future Outlook and Potential Applications

Despite the challenges, the future of additive PCB manufacturing looks promising. As the technology matures and overcomes current limitations, it has the potential to revolutionize the way multilayer PCBs are designed and manufactured.

Potential Applications of Additive PCB Manufacturing

- Rapid Prototyping and Low-Volume Production: Additive manufacturing is well-suited for quick prototyping and low-volume production of PCBs, enabling faster time-to-market for new products and designs.

- Customized and On-Demand PCBs: Additive manufacturing allows for the creation of customized PCBs tailored to specific applications, with the ability to produce them on-demand, reducing inventory costs and lead times.

- Embedded Electronics and 3D Printed Circuits: Additive manufacturing enables the integration of electronic components directly into the PCB structure, creating opportunities for more compact and functional designs.

- Aerospace and Defense Applications: The ability to create lightweight, complex, and high-performance PCBs using additive manufacturing is particularly attractive for aerospace and defense applications, where weight reduction and customization are critical.

Research and Development Initiatives

To address the challenges and realize the potential of additive PCB manufacturing, several research and development initiatives are underway. These efforts focus on developing new materials, improving process performance, and creating software tools to support additive PCB design and manufacturing.

| Initiative | Focus | Participants |

|---|---|---|

| NextFlex | Flexible Hybrid Electronics | Industry, Academia, Government |

| FAME | Additive Manufacturing of Electronics | European Consortium |

| AFRL | 3D Printed Electronics | U.S. Air Force Research Laboratory |

These initiatives bring together experts from industry, academia, and government to collaborate on advancing additive PCB manufacturing technology and accelerating its adoption.

Conclusion

Additive manufacturing has the potential to revolutionize multilayer PCB manufacturing by offering faster prototyping, reduced waste, increased design flexibility, and shorter lead times. While challenges related to material properties, resolution, scalability, and standardization remain, ongoing research and development efforts are working to address these issues.

As the technology matures, additive PCB manufacturing is poised to transform the electronics industry, enabling new applications and design possibilities. By embracing this innovative approach, companies can stay ahead of the curve and capitalize on the benefits of additive manufacturing in PCB production.

Frequently Asked Questions (FAQ)

-

What is additive manufacturing, and how does it differ from traditional PCB manufacturing methods?

Additive manufacturing, also known as 3D printing, is a process that builds objects layer by layer using materials such as plastics, metals, or ceramics. In contrast, traditional PCB manufacturing methods, such as subtractive manufacturing, remove material to create the desired pattern. Additive manufacturing offers several advantages, including faster prototyping, reduced waste, and increased design flexibility. -

What are the key benefits of using additive manufacturing for multilayer PCB production?

The key benefits of using additive manufacturing for multilayer PCB production include rapid prototyping, reduced waste, increased design flexibility, and shorter lead times. Additive manufacturing enables quick and cost-effective prototyping, allows for the creation of complex geometries and unique features, and streamlines the production process, resulting in faster turnaround times. -

What are the main challenges and limitations of additive PCB manufacturing?

The main challenges and limitations of additive PCB manufacturing include material properties and performance, resolution and feature size, process scalability and throughput, and standardization and qualification. Developing materials that match the performance of traditionally manufactured PCBs, improving process speed and scalability, and establishing industry-wide standards are crucial for widespread adoption. -

What are some potential applications of additive PCB manufacturing?

Potential applications of additive PCB manufacturing include rapid prototyping and low-volume production, customized and on-demand PCBs, embedded electronics and 3D printed circuits, and aerospace and defense applications. Additive manufacturing is well-suited for quick prototyping, creating tailored PCBs for specific applications, and producing lightweight and complex designs for demanding industries. -

How can companies and researchers address the challenges and realize the potential of additive PCB manufacturing?

To address the challenges and realize the potential of additive PCB manufacturing, companies and researchers can collaborate on research and development initiatives focusing on developing new materials, improving process performance, and creating software tools to support additive PCB design and manufacturing. By working together and investing in these areas, the industry can accelerate the adoption of additive PCB manufacturing and unlock its full potential.

Leave a Reply