Understanding the PCB Supply Chain

Before diving into the challenges, let’s briefly understand the PCB supply chain. The supply chain involves multiple stages, from raw material procurement to the final delivery of the finished product. The key stages include:

- Raw Material Sourcing

- PCB Design and Engineering

- PCB Fabrication

- Component Procurement

- PCB Assembly

- Testing and Quality Control

- Packaging and Shipping

Each stage presents its own set of challenges that can impact the overall efficiency and cost-effectiveness of the supply chain.

Top Challenges in PCB Supply Chain Management

1. Raw Material Availability and Price Fluctuations

One of the primary challenges in PCB supply chain management is the availability and price volatility of raw materials. PCBs require various materials, such as copper, fiberglass, and resins, which are subject to market fluctuations. Supply shortages or price hikes can significantly impact the cost and lead time of PCB production.

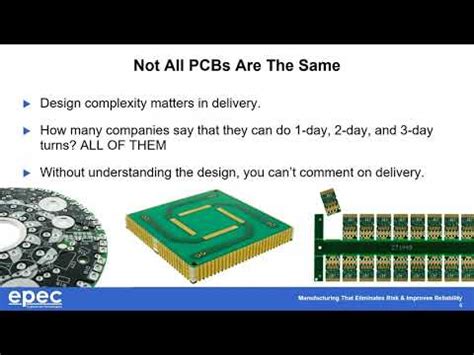

2. Rapid Technological Advancements

The electronics industry is known for its rapid technological advancements. As new technologies emerge, PCB designs become more complex and require advanced manufacturing capabilities. Keeping up with these advancements can be challenging for manufacturers, as they need to invest in new equipment, processes, and skilled personnel.

3. Shortened Product Life Cycles

Another challenge in the electronics industry is the shortened product life cycles. Consumer demand for the latest and greatest technology puts pressure on manufacturers to quickly bring new products to market. This compressed timeline leaves little room for error in the supply chain, as delays can result in missed market opportunities.

4. Global Supply Chain Complexity

The electronics industry relies heavily on a global supply chain, with components and materials sourced from various countries. This complexity presents challenges such as longer lead times, cultural differences, language barriers, and varying quality standards. Managing a global supply chain requires robust communication, coordination, and risk management strategies.

5. Counterfeit Components

Counterfeit components pose a significant threat to the electronics industry. These fake components can lead to product failures, safety hazards, and reputational damage. Identifying and preventing the infiltration of counterfeit components in the supply chain is a critical challenge for manufacturers.

How Your PCB Contract Manufacturer Can Help

Partnering with a reliable PCB contract manufacturer can help mitigate these supply chain challenges. Here’s how:

1. Established Supplier Network

PCB contract manufacturers have established relationships with a network of trusted suppliers. They can leverage these relationships to ensure a stable supply of raw materials and components, even during times of shortages or price fluctuations.

2. Technological Expertise

Leading PCB contract manufacturers invest in state-of-the-art equipment and employ skilled engineers to stay ahead of technological advancements. They can provide valuable insights and support in designing and manufacturing complex PCBs, ensuring that your products remain competitive in the market.

3. Flexible Manufacturing Capabilities

PCB contract manufacturers offer flexible manufacturing capabilities to accommodate varying production volumes and timelines. They can quickly ramp up or down production based on your needs, helping you respond to market demands and shorter product life cycles.

4. Global Footprint and Logistics Support

Many PCB contract manufacturers have a global presence, with facilities located in strategic regions worldwide. This global footprint allows them to optimize supply chain logistics, reduce lead times, and minimize the risks associated with a complex global supply chain. They can also provide support in navigating cultural differences and ensuring compliance with international regulations.

5. Rigorous Quality Control and Anti-Counterfeiting Measures

Reputable PCB contract manufacturers implement strict quality control processes and anti-counterfeiting measures. They have robust systems in place to inspect incoming materials, monitor production processes, and perform thorough testing to ensure the authenticity and reliability of the components used in your PCBs.

Frequently Asked Questions (FAQ)

-

Q: How can I ensure the quality of my PCBs when outsourcing to a contract manufacturer?

A: Partner with a PCB contract manufacturer that has a proven track record of quality and holds relevant certifications such as ISO 9001 and IPC standards. Establish clear quality requirements and conduct regular audits to ensure adherence to your specifications. -

Q: What should I consider when selecting a PCB contract manufacturer?

A: When choosing a PCB contract manufacturer, consider factors such as their technical capabilities, quality control processes, financial stability, communication and responsiveness, and customer references. Look for a manufacturer that aligns with your specific needs and can provide a long-term partnership. -

Q: How can I protect my intellectual property when working with a PCB contract manufacturer?

A: Safeguard your intellectual property by signing non-disclosure agreements (NDAs) and conducting thorough background checks on potential manufacturing partners. Work with a reputable PCB contract manufacturer that has a strong track record of protecting client confidentiality. -

Q: How can I minimize the risk of supply chain disruptions?

A: Diversify your supplier base to avoid reliance on a single source. Establish long-term relationships with trusted suppliers and maintain open communication to stay informed about potential disruptions. Implement risk management strategies, such as buffer inventories and alternative sourcing options. -

Q: What are the benefits of partnering with a local PCB contract manufacturer versus an overseas one?

A: Local PCB contract manufacturers offer advantages such as shorter lead times, easier communication, and faster problem resolution. They may also have a better understanding of local regulations and market requirements. However, overseas manufacturers may offer cost advantages and access to a broader supplier network. Consider your specific needs and priorities when making the decision.

Conclusion

The electronics manufacturing industry faces numerous challenges in PCB supply chain management, from raw material availability to global complexity and counterfeit components. Partnering with a reliable PCB contract manufacturer can help overcome these challenges by providing access to an established supplier network, technological expertise, flexible manufacturing capabilities, global logistics support, and rigorous quality control measures.

When selecting a PCB contract manufacturer, consider their technical capabilities, quality control processes, communication, and ability to protect your intellectual property. By establishing a strong partnership with a trusted manufacturer, you can navigate the complexities of the PCB supply chain and ensure the success of your electronics products in the market.

Leave a Reply