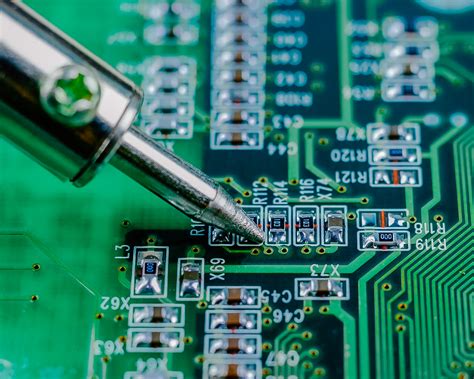

Introduction to PCB Assembly

PCB (Printed Circuit Board) assembly is the process of attaching electronic components to a printed circuit board to create a functional electronic device. This process involves various techniques and services, depending on the complexity and requirements of the project. In this article, we will discuss the different types of PCB assembly services and provide tips to ensure your PCB assembly is a success.

Types of PCB Assembly Services

1. Through-Hole Assembly (THA)

Through-hole assembly is a traditional PCB assembly method where component leads are inserted into drilled holes on the PCB and soldered onto the opposite side of the board. This method is suitable for larger components and provides strong mechanical bonds, making it ideal for high-reliability applications.

Advantages of Through-Hole Assembly

- Strong mechanical bonds

- Suitable for larger components

- Ideal for high-reliability applications

Disadvantages of Through-Hole Assembly

- Slower assembly process compared to surface mount technology

- Requires more space on the PCB

- Higher cost for high-volume production

2. Surface Mount Assembly (SMT)

Surface mount assembly is a modern PCB assembly technique where components are mounted directly onto the surface of the PCB without the need for drilled holes. This method allows for smaller components and higher component density, making it suitable for compact and complex designs.

Advantages of Surface Mount Assembly

- Faster assembly process compared to through-hole assembly

- Allows for smaller components and higher component density

- Cost-effective for high-volume production

Disadvantages of Surface Mount Assembly

- Requires specialized equipment and skilled operators

- More susceptible to thermal stress and vibration

- Difficult to repair or replace individual components

3. Mixed Assembly

Mixed assembly is a combination of through-hole and surface mount assembly techniques. This method is used when a PCB design requires both large through-hole components and small surface mount components. Mixed assembly provides the benefits of both assembly methods while accommodating diverse component requirements.

Advantages of Mixed Assembly

- Accommodates diverse component requirements

- Combines the benefits of through-hole and surface mount assembly

- Suitable for complex PCB designs

Disadvantages of Mixed Assembly

- Requires skilled operators familiar with both assembly techniques

- May increase assembly time and cost compared to single assembly method

4. Flexible PCB Assembly

Flexible PCB assembly involves assembling components on a flexible circuit board made of thin, flexible materials such as polyimide or polyester. This type of assembly is suitable for applications that require the PCB to bend, fold, or fit into tight spaces.

Advantages of Flexible PCB Assembly

- Allows for PCB flexibility and conformity to tight spaces

- Reduces overall weight and size of the electronic device

- Improves reliability in applications with vibration or motion

Disadvantages of Flexible PCB Assembly

- Higher material and manufacturing costs compared to rigid PCBs

- Requires specialized assembly techniques and equipment

- Limited component options due to the flexible nature of the PCB

5. Rigid-flex PCB Assembly

Rigid-flex PCB assembly combines the benefits of both rigid and flexible PCBs. This type of assembly uses a combination of rigid and flexible substrates, allowing for the integration of multiple PCB Layers and the ability to bend or fold certain sections of the board.

Advantages of Rigid-Flex PCB Assembly

- Combines the benefits of rigid and flexible PCBs

- Allows for complex, multi-layer designs

- Improves reliability and reduces the need for connectors

Disadvantages of Rigid-Flex PCB Assembly

- Higher design and manufacturing costs compared to single-type PCBs

- Requires specialized design and assembly expertise

- Longer lead times due to the complex manufacturing process

Tips for Successful PCB Assembly

-

Choose the right PCB assembly service: Select the appropriate assembly method based on your project requirements, such as component types, PCB complexity, and production volume.

-

Design for manufacturability (DFM): Follow DFM guidelines to ensure your PCB design is optimized for the chosen assembly method. This includes considerations for component placement, trace spacing, and solder mask design.

-

Use high-quality components: Source components from reputable suppliers to ensure reliability and compatibility with your chosen assembly method.

-

Communicate clearly with your assembly provider: Provide detailed documentation, including bill of materials (BOM), assembly drawings, and any special instructions to avoid misunderstandings and delays.

-

Conduct thorough testing and quality control: Implement a rigorous testing and quality control process to identify and address any issues early in the assembly process, reducing the risk of costly rework or product failures.

PCB Assembly Services Comparison

| Assembly Service | Suitable Components | Complexity | Production Volume | Cost |

|---|---|---|---|---|

| Through-Hole | Larger components | Low to medium | Low to medium | High for low volume |

| Surface Mount | Smaller components | Medium to high | High | Low for high volume |

| Mixed | Diverse components | High | Medium to high | Moderate to high |

| Flexible | Limited options | Medium to high | Low to medium | High |

| Rigid-Flex | Diverse components | Very high | Low to medium | Very high |

Frequently Asked Questions (FAQ)

-

Q: How do I choose the right PCB assembly service for my project?

A: Consider factors such as the types of components required, PCB complexity, production volume, and budget when selecting a PCB assembly service. Consult with your assembly provider to determine the most suitable method for your specific project. -

Q: What is the difference between through-hole and surface mount assembly?

A: Through-hole assembly involves inserting component leads into drilled holes on the PCB and soldering them on the opposite side, while surface mount assembly mounts components directly onto the surface of the PCB without the need for drilled holes. -

Q: Can I combine different assembly methods on a single PCB?

A: Yes, mixed assembly allows for the combination of through-hole and surface mount assembly techniques on a single PCB to accommodate diverse component requirements. -

Q: What are the benefits of using flexible or rigid-Flex PCBs?

A: Flexible PCBs allow for the PCB to bend, fold, or fit into tight spaces, reducing overall weight and size while improving reliability in applications with vibration or motion. Rigid-flex PCBs combine the benefits of rigid and flexible PCBs, allowing for complex, multi-layer designs and reducing the need for connectors. -

Q: How can I ensure the success of my PCB assembly project?

A: To ensure the success of your PCB assembly project, choose the right assembly service, design for manufacturability, use high-quality components, communicate clearly with your assembly provider, and conduct thorough testing and quality control.

Conclusion

Understanding the different types of PCB assembly services and their respective advantages and disadvantages is crucial for selecting the most suitable method for your project. By following the tips provided and working closely with your assembly provider, you can ensure the success of your PCB assembly project, resulting in a reliable and high-quality electronic device.

Leave a Reply