Introduction to PCB Fabrication

Printed Circuit Board (PCB) fabrication is the process of designing, manufacturing, and assembling electronic circuits on a flat insulating substrate. PCBs are essential components in almost all modern electronic devices, from smartphones and computers to industrial equipment and medical devices. The fabrication process involves several steps, including design, layout, etching, drilling, plating, and assembly.

The Importance of Prototype PCB Fabrication

Prototype PCB fabrication is a crucial step in the development of new electronic products. It allows designers and engineers to test and validate their designs before moving to full-scale production. Prototyping helps identify potential issues, such as design flaws, component incompatibilities, and manufacturing challenges, early in the development process. This saves time and money by avoiding costly mistakes and delays in the final production stage.

Benefits of Turnkey Prototype PCB Fabrication & Assembly

Turnkey prototype PCB fabrication and assembly offer several advantages over traditional in-house prototyping:

-

Expertise: Turnkey PCB fabrication companies have experienced engineers and technicians who specialize in PCB design, fabrication, and assembly. They can provide valuable insights and recommendations to optimize your design for manufacturability and performance.

-

Advanced Equipment: Turnkey PCB fabrication facilities are equipped with state-of-the-art machinery and tools, ensuring high-quality and precise manufacturing of your prototype PCBs.

-

Time Savings: By outsourcing your prototype PCB fabrication and assembly, you can save time and focus on other aspects of your product development, such as software development and system integration.

-

Cost-Effectiveness: Turnkey PCB fabrication companies offer competitive pricing for prototype quantities, making it more cost-effective than investing in in-house prototyping equipment and personnel.

The PCB Fabrication Process

The PCB fabrication process consists of several steps, each requiring specific expertise and equipment. Here’s an overview of the main stages:

1. PCB Design and Layout

The first step in PCB fabrication is designing the circuit schematic and creating the PCB layout. This involves selecting components, determining their placement, and routing the connections between them. PCB design software, such as Altium Designer, Eagle, or KiCad, is used to create the schematic and layout files.

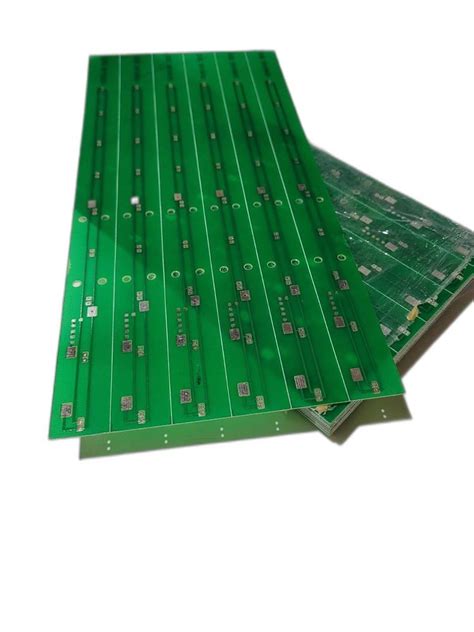

2. PCB Fabrication

Once the design files are ready, the fabrication process begins:

-

Substrate Preparation: The PCB substrate, typically made of fiberglass or other insulating material, is cut to the required size and cleaned.

-

Copper Cladding: A thin layer of copper is laminated onto the substrate using heat and pressure.

-

Photoresist Application: A light-sensitive photoresist is applied to the copper layer.

-

Exposure and Developing: The photoresist is exposed to UV light through a photomask, which contains the PCB layout pattern. The exposed areas of the photoresist are then removed using a developer solution.

-

Etching: The exposed copper areas are etched away using a chemical solution, leaving only the desired copper traces.

-

Drilling: Holes are drilled through the PCB for through-hole components and vias.

-

Plating: The holes are plated with copper to establish electrical connections between layers.

-

Solder Mask Application: A solder mask is applied to the PCB surface to protect the copper traces and prevent solder bridges.

-

Silkscreen Printing: Text and symbols are printed on the PCB surface using silkscreen printing for component identification and assembly instructions.

3. PCB Assembly

After the PCB fabrication is complete, the components are assembled onto the board:

-

Solder Paste Application: Solder paste is applied to the PCB pads using a stencil or syringe.

-

Component Placement: Components are placed on the PCB, either manually or using automated pick-and-place machines.

-

Reflow Soldering: The PCB is heated in a reflow oven, melting the solder paste and forming permanent electrical connections between the components and the PCB.

-

Inspection and Testing: The assembled PCB is visually inspected and electrically tested to ensure proper functionality and quality.

Choosing a Turnkey Prototype PCB Fabrication & Assembly Partner

When selecting a turnkey prototype PCB fabrication and assembly partner, consider the following factors:

-

Experience and Expertise: Look for a company with a proven track record in PCB fabrication and assembly, especially in your specific industry or application.

-

Manufacturing Capabilities: Ensure the company has the necessary equipment and processes to handle your prototype PCB requirements, such as multilayer boards, fine-pitch components, or specialized materials.

-

Quality Control: Inquire about the company’s quality control processes and certifications, such as ISO 9001, IPC standards, or UL listing.

-

Turnaround Time: Consider the company’s typical turnaround times for prototype quantities and whether they offer expedited services if needed.

-

Customer Support: Choose a partner that provides responsive and knowledgeable customer support, from the initial design review to the final delivery of your prototype PCBs.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for prototype PCBs?

Most turnkey PCB fabrication companies offer low minimum order quantities for prototypes, typically starting from 5 to 10 pieces. Some companies may even offer single-piece prototypes for simple designs. -

How long does it take to fabricate and assemble prototype PCBs?

Turnaround times for prototype PCBs vary depending on the complexity of the design, the fabrication and assembly processes required, and the workload of the manufacturing facility. Typical turnaround times range from 3 to 15 business days, with some companies offering expedited services for faster delivery. -

What files do I need to provide for PCB fabrication and assembly?

To start the PCB fabrication and assembly process, you’ll need to provide the following files: - Gerber files (.gbr) for each layer of the PCB

- Drill files (.drl or .txt) specifying the hole sizes and locations

- Bill of Materials (BOM) listing all components and their quantities

-

Assembly drawing or placement file (.csv, .txt, or .xls) indicating the component locations and orientations

-

Can I get a quotation for my prototype PCB before placing an order?

Yes, most turnkey PCB fabrication companies offer free quotations based on your design files and requirements. Simply submit your files and specifications through their website or by contacting their sales team, and they will provide you with a detailed quotation, including pricing and lead time. -

What if I need to make changes to my prototype PCB design after submitting the files?

If you need to make changes to your design after submitting the files, contact your PCB fabrication partner as soon as possible. Depending on the stage of the fabrication process, they may be able to accommodate minor changes without significant impact on the lead time or cost. However, major changes may require restarting the fabrication process and incur additional costs.

Conclusion

Turnkey prototype PCB fabrication and assembly services provide an efficient and cost-effective solution for bringing your electronic product ideas to life. By partnering with an experienced and reliable PCB fabrication company, you can benefit from their expertise, advanced equipment, and streamlined processes, ensuring high-quality prototype PCBs that meet your design requirements and performance expectations.

| Advantages of Turnkey Prototype PCB Fabrication & Assembly | Description |

|---|---|

| Expertise | Access to experienced engineers and technicians specializing in PCB design, fabrication, and assembly |

| Advanced Equipment | State-of-the-art machinery and tools for high-quality and precise manufacturing |

| Time Savings | Outsourcing allows you to focus on other aspects of product development |

| Cost-Effectiveness | Competitive pricing for prototype quantities compared to in-house prototyping |

When choosing a turnkey prototype PCB fabrication and assembly partner, consider factors such as experience, manufacturing capabilities, quality control, turnaround time, and customer support. By selecting the right partner, you can accelerate your product development process, reduce risks, and achieve a successful prototype that paves the way for full-scale production.

Leave a Reply