What is PCB Burn-in Testing?

PCB burn-in testing is a critical process in printed circuit board (PCB) manufacturing that involves subjecting the boards to elevated temperatures and operating conditions for an extended period. The primary goal of this testing is to identify and eliminate early-life failures, ensuring that the PCBs delivered to customers are reliable and perform as expected.

During the burn-in process, PCBs are placed in a controlled environment where they are exposed to high temperatures, typically above their normal operating range. The boards are then powered on and run through a series of tests to simulate real-world operating conditions. This process helps to accelerate the aging of the components and the board itself, allowing manufacturers to detect and address any weaknesses or defects that may lead to premature failure.

Benefits of PCB Burn-in Testing

-

Improved reliability: By identifying and eliminating early-life failures, burn-in testing ensures that the PCBs delivered to customers are more reliable and less likely to fail during operation.

-

Reduced warranty costs: By catching defects early in the manufacturing process, companies can reduce the number of warranty claims and associated costs.

-

Enhanced customer satisfaction: Customers who receive reliable, high-quality PCBs are more likely to be satisfied with their purchase and return for future business.

-

Compliance with industry standards: Many industries, such as aerospace, defense, and medical devices, have strict reliability requirements that necessitate burn-in testing.

The PCB Burn-in Testing Process

The PCB burn-in testing process typically involves several steps:

1. Pre-burn-in Inspection

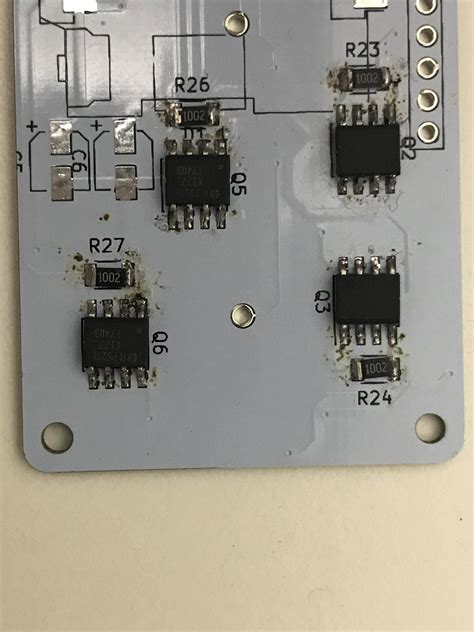

Before the burn-in process begins, PCBs undergo a thorough visual inspection to identify any obvious defects or issues. This may include checking for proper component placement, solder joint quality, and any signs of physical damage.

2. Burn-in Chamber Setup

PCBs are placed in a specialized burn-in chamber that is designed to maintain a consistent, elevated temperature throughout the testing process. The chamber is equipped with racks or slots to hold the boards securely in place and ensure proper airflow.

3. Temperature Elevation

The burn-in chamber gradually raises the temperature to the desired level, which is typically between 125°C and 150°C (257°F to 302°F). The temperature is carefully controlled to ensure that all boards are exposed to the same conditions.

4. Power-on and Functional Testing

Once the target temperature is reached, the PCBs are powered on and subjected to a series of functional tests. These tests are designed to simulate real-world operating conditions and may include:

- Power cycling

- Signal integrity testing

- Communication protocol testing

- Stress testing of specific components

The functional tests are typically automated and monitored by specialized software to ensure consistent and accurate results.

5. Duration of Burn-in

The duration of the burn-in process varies depending on the specific requirements of the PCB and the industry it serves. Typical burn-in times range from 24 to 168 hours (1 to 7 days). Longer burn-in times may be necessary for high-reliability applications or when required by industry standards.

6. Post-burn-in Inspection and Testing

After the burn-in process is complete, the PCBs are removed from the chamber and allowed to cool to room temperature. They then undergo a final visual inspection and a series of post-burn-in functional tests to verify that they are still operating correctly and have not suffered any damage during the process.

Factors Affecting PCB Burn-in Testing

Several factors can influence the effectiveness and duration of PCB burn-in testing:

1. PCB Complexity

More complex PCBs, with a higher number of components and layers, may require longer burn-in times to ensure thorough testing of all components and interconnections.

2. Component Types

Different types of components may have varying sensitivity to high temperatures and may require specific burn-in conditions. For example, some components may need to be powered on during the entire burn-in process, while others may only need to be subjected to the elevated temperature.

3. Industry Standards and Regulations

Certain industries, such as aerospace, defense, and medical devices, have strict reliability requirements that dictate the burn-in conditions and duration. These standards ensure that the PCBs used in these applications can withstand the rigors of their intended environment.

4. Customer Requirements

Some customers may have specific burn-in requirements that go beyond industry standards. These requirements may be based on the customer’s experience with their particular application or a desire for an added level of reliability assurance.

Challenges in PCB Burn-in Testing

While PCB burn-in testing is a valuable process for ensuring reliability, it does present some challenges:

1. Cost

Burn-in testing requires specialized equipment and can be time-consuming, adding to the overall cost of PCB manufacturing. However, the long-term benefits of improved reliability and reduced warranty costs often outweigh the initial expense.

2. Potential for Damage

The high temperatures and extended duration of burn-in testing can potentially cause damage to some components if not carefully controlled. Manufacturers must strike a balance between thorough testing and minimizing the risk of damage.

3. False Failures

In some cases, burn-in testing may identify failures that would not occur under normal operating conditions. These “false failures” can lead to unnecessary rework or scrap, increasing costs and production time.

Alternatives to Traditional PCB Burn-in Testing

While traditional burn-in testing remains the most common approach, some alternatives have emerged:

1. Highly Accelerated Stress Screening (HASS)

HASS is a technique that subjects PCBs to even higher stress levels than traditional burn-in testing, but for a shorter duration. This approach can be useful for identifying weaknesses more quickly but may not be suitable for all applications.

2. Environmental Stress Screening (ESS)

ESS involves subjecting PCBs to a variety of environmental stresses, such as temperature cycling, vibration, and humidity. This approach can help identify potential issues related to the PCB’s interaction with its intended environment.

3. Predictive Maintenance

Advancements in sensor technology and data analytics have enabled the development of predictive maintenance techniques. By monitoring PCBs in real-time and analyzing performance data, manufacturers can identify potential issues before they lead to failure. While not a replacement for burn-in testing, predictive maintenance can complement the process and further enhance reliability.

Conclusion

PCB burn-in testing is a critical process in ensuring the reliability and longevity of printed circuit boards. By subjecting PCBs to elevated temperatures and operating conditions, manufacturers can identify and eliminate early-life failures, reducing warranty costs and enhancing customer satisfaction. While burn-in testing does present some challenges, the benefits it provides make it an essential part of the PCB manufacturing process.

As technology continues to advance, new approaches to reliability testing may emerge, but the fundamental goal of delivering high-quality, dependable PCBs will remain constant. By understanding and continually refining the burn-in testing process, manufacturers can meet the evolving needs of their customers and the industries they serve.

Frequently Asked Questions (FAQ)

1. What is the purpose of PCB burn-in testing?

The primary purpose of PCB burn-in testing is to identify and eliminate early-life failures by subjecting the boards to elevated temperatures and operating conditions for an extended period.

2. What temperature range is typically used in PCB burn-in testing?

The temperature range for PCB burn-in testing is typically between 125°C and 150°C (257°F to 302°F), which is above the normal operating range of the PCBs.

3. How long does a typical PCB burn-in test last?

The duration of a PCB burn-in test can vary depending on the specific requirements of the PCB and the industry it serves. Typical burn-in times range from 24 to 168 hours (1 to 7 days).

4. Are there any industries that have specific requirements for PCB burn-in testing?

Yes, industries such as aerospace, defense, and medical devices have strict reliability requirements that necessitate specific burn-in testing conditions and durations to ensure compliance with industry standards.

5. Are there any alternatives to traditional PCB burn-in testing?

While traditional burn-in testing remains the most common approach, alternatives such as Highly Accelerated Stress Screening (HASS), Environmental Stress Screening (ESS), and predictive maintenance techniques have emerged to complement or enhance the reliability testing process.

| Aspect | Description |

|---|---|

| Purpose | Identify and eliminate early-life failures |

| Temperature Range | 125°C to 150°C (257°F to 302°F) |

| Duration | 24 to 168 hours (1 to 7 days) |

| Industry Requirements | Aerospace, defense, medical devices (strict reliability standards) |

| Alternatives | Highly Accelerated Stress Screening (HASS), Environmental Stress Screening (ESS), predictive maintenance |

Leave a Reply