Introduction to Embedded PCB Assemblies

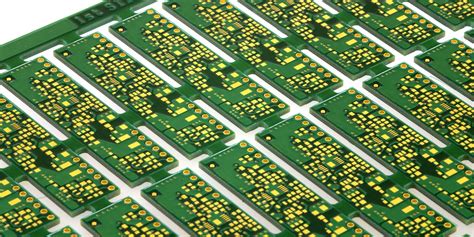

Embedded PCB (Printed Circuit Board) assemblies have revolutionized the electronics industry by enabling the creation of compact, high-performance devices. These assemblies integrate various components, such as microprocessors, memory modules, and power management units, directly onto a single PCB. By doing so, embedded PCB assemblies offer several advantages over traditional PCB designs, including improved performance, reduced size, and enhanced reliability.

In this article, we will explore the potential of embedded PCB assemblies and how they can be leveraged to improve the performance of electronic devices. We will delve into the key benefits of embedded PCB assemblies, discuss the various applications where they excel, and provide insights into the design and manufacturing process.

The Benefits of Embedded PCB Assemblies

Improved Performance

One of the primary advantages of embedded PCB assemblies is their ability to improve the overall performance of electronic devices. By integrating components directly onto the PCB, the distance between these components is minimized, reducing signal propagation delays and improving signal integrity. This results in faster data transfer rates, lower latency, and higher bandwidth, which are crucial for applications that require high-speed processing and real-time responsiveness.

Moreover, embedded PCB assemblies enable better power management and distribution. With components placed in close proximity, power delivery becomes more efficient, reducing power loss and minimizing the risk of voltage drops. This leads to improved power efficiency and longer battery life in portable devices.

Space Optimization

Another significant benefit of embedded PCB assemblies is their ability to optimize space utilization. Traditional PCB designs often require separate boards for different functions, resulting in larger device footprints and increased packaging complexity. In contrast, embedded PCB assemblies allow for the integration of multiple functions onto a single board, reducing the overall size of the device.

By consolidating components and eliminating the need for separate boards, embedded PCB assemblies enable the creation of more compact and lightweight devices. This is particularly advantageous in applications where space is limited, such as wearable technology, mobile devices, and aerospace systems.

Enhanced Reliability

Embedded PCB assemblies also contribute to enhanced reliability of electronic devices. By reducing the number of interconnects and minimizing the distance between components, the risk of signal degradation and interference is mitigated. This results in improved signal integrity and reduced susceptibility to electromagnetic interference (EMI) and radio frequency interference (RFI).

Furthermore, embedded PCB assemblies often employ advanced manufacturing techniques, such as High-Density Interconnect (HDI) technology, which allows for finer trace widths and smaller via sizes. This enables better control over signal routing and reduces the likelihood of manufacturing defects, leading to higher reliability and longer product lifetimes.

Applications of Embedded PCB Assemblies

Embedded PCB assemblies find applications across various industries and sectors where high performance, compact size, and reliability are crucial. Some of the key application areas include:

Consumer Electronics

In the consumer electronics domain, embedded PCB assemblies are widely used in devices such as smartphones, tablets, smartwatches, and gaming consoles. These assemblies enable the integration of powerful processors, high-capacity memory, and advanced sensors in slim and lightweight form factors. By leveraging embedded PCB technology, consumer electronics manufacturers can deliver feature-rich devices with extended battery life and improved user experiences.

Automotive Electronics

The automotive industry has witnessed a significant increase in the adoption of embedded PCB assemblies. Modern vehicles are equipped with a plethora of electronic systems, including infotainment systems, advanced driver assistance systems (ADAS), and engine control units (ECUs). Embedded PCB assemblies enable the integration of these systems into compact and robust modules, ensuring reliable performance in harsh automotive environments. They also contribute to weight reduction and improved fuel efficiency in vehicles.

Medical Devices

Embedded PCB assemblies play a crucial role in the development of medical devices, such as patient monitoring systems, diagnostic equipment, and implantable devices. These assemblies enable the integration of sensors, processors, and communication modules into compact and lightweight devices that can be worn or implanted in patients. By leveraging embedded PCB technology, medical device manufacturers can create devices that are minimally invasive, reliable, and capable of real-time monitoring and data transmission.

Industrial Automation

In the field of industrial automation, embedded PCB assemblies are used in a wide range of applications, including process control systems, robotics, and machine vision systems. These assemblies enable the integration of sensors, actuators, and control electronics into compact and rugged modules that can withstand harsh industrial environments. By leveraging embedded PCB technology, industrial automation systems can achieve higher performance, improved reliability, and reduced downtime.

Designing and Manufacturing Embedded PCB Assemblies

Designing and manufacturing embedded PCB assemblies requires specialized expertise and advanced techniques. The process involves several key considerations and steps:

Component Selection

The first step in designing an embedded PCB assembly is selecting the appropriate components. This involves considering factors such as performance requirements, power consumption, thermal characteristics, and compatibility with the overall system. Designers must carefully evaluate and choose components that meet the specific needs of the application while ensuring optimal integration onto the PCB.

PCB Layout and Routing

Once the components are selected, the next step is to create the PCB layout and routing. This involves determining the optimal placement of components on the board, designing the interconnects, and defining the signal paths. Designers must consider factors such as signal integrity, power distribution, thermal management, and manufacturability when creating the PCB layout. Advanced design tools and simulation software are often used to optimize the layout and ensure the desired performance.

High-Density Interconnect (HDI) Technology

HDI technology is a key enabler for embedded PCB assemblies. HDI PCBs feature finer trace widths, smaller via sizes, and higher layer counts compared to traditional PCBs. This allows for denser component integration and improved signal routing. HDI technology also enables the use of micro via and blind via structures, which further enhance the compactness and performance of embedded PCB assemblies.

Manufacturing Process

The manufacturing process for embedded PCB assemblies involves several specialized techniques. These include:

- Surface Mount Technology (SMT): SMT is used to mount components directly onto the surface of the PCB. This technique enables high-density component placement and improved manufacturing efficiency.

- Chip-on-Board (COB) Technology: COB technology involves bonding bare die directly onto the PCB substrate. This eliminates the need for traditional packaging and allows for even higher levels of integration and miniaturization.

- 3D Packaging: 3D packaging techniques, such as package-on-package (PoP) and through-silicon via (TSV), enable vertical stacking of components and interconnects. This further enhances the density and performance of embedded PCB assemblies.

Testing and Quality Assurance

Rigorous testing and quality assurance processes are essential to ensure the reliability and performance of embedded PCB assemblies. This includes functional testing, environmental testing, and reliability testing. Automated test equipment (ATE) and specialized test fixtures are often used to streamline the testing process and identify any potential issues early in the manufacturing cycle. Quality assurance procedures, such as visual inspection and X-ray inspection, are also employed to detect and prevent manufacturing defects.

Frequently Asked Questions (FAQ)

1. What is the difference between embedded PCB assemblies and traditional PCB assemblies?

Embedded PCB assemblies integrate components directly onto the PCB substrate, resulting in higher density, improved performance, and reduced size compared to traditional PCB assemblies, which typically have components mounted on the surface of the board.

2. What are the key benefits of using embedded PCB assemblies in electronic devices?

The key benefits of using embedded PCB assemblies include improved performance, space optimization, enhanced reliability, and the ability to create compact and lightweight devices with advanced functionality.

3. In which industries are embedded PCB assemblies commonly used?

Embedded PCB assemblies are commonly used in various industries, including consumer electronics, automotive electronics, medical devices, industrial automation, aerospace, and telecommunications.

4. What is High-Density Interconnect (HDI) technology, and how does it benefit embedded PCB assemblies?

HDI technology involves the use of finer trace widths, smaller via sizes, and higher layer counts in PCB design. It enables denser component integration, improved signal routing, and enhanced performance in embedded PCB assemblies.

5. What are the key considerations when designing and manufacturing embedded PCB assemblies?

The key considerations when designing and manufacturing embedded PCB assemblies include component selection, PCB layout and routing, the use of HDI technology, specialized manufacturing techniques such as SMT and COB, and rigorous testing and quality assurance processes.

Conclusion

Embedded PCB assemblies have emerged as a game-changer in the electronics industry, offering a multitude of benefits that enable the creation of high-performance, compact, and reliable devices. By leveraging advanced technologies such as HDI and specialized manufacturing techniques, embedded PCB assemblies unlock the potential for improved performance, space optimization, and enhanced reliability across various applications.

As the demand for smaller, faster, and more feature-rich electronic devices continues to grow, embedded PCB assemblies will play an increasingly crucial role in driving innovation and meeting the evolving needs of consumers and industries alike. By understanding the potential of embedded PCB assemblies and leveraging their advantages, designers and manufacturers can create cutting-edge devices that push the boundaries of performance and functionality.

However, the successful implementation of embedded PCB assemblies requires specialized expertise and a deep understanding of the design and manufacturing processes involved. From component selection and PCB layout to HDI technology and quality assurance, each step of the process must be carefully considered and executed to ensure optimal results.

As technology continues to advance, it is expected that embedded PCB assemblies will further evolve, incorporating new materials, manufacturing techniques, and integration approaches. This will open up even more possibilities for creating highly integrated, high-performance devices that cater to the ever-changing needs of the market.

In conclusion, embedded PCB assemblies represent a significant opportunity for improving the performance of electronic devices across various industries. By harnessing the potential of these assemblies and staying at the forefront of technological advancements, designers and manufacturers can deliver innovative solutions that meet the demanding requirements of today’s and tomorrow’s applications.

| Characteristic | Traditional PCB Assemblies | Embedded PCB Assemblies |

|---|---|---|

| Component Integration | Surface-mounted components | Components embedded directly onto PCB substrate |

| Density | Lower component density | Higher component density |

| Size | Larger device footprint | Reduced device size and weight |

| Performance | Slower data transfer rates and higher latency | Faster data transfer rates and lower latency |

| Power Efficiency | Lower power efficiency due to longer signal paths | Improved power efficiency due to shorter signal paths |

| Reliability | Higher risk of signal degradation and interference | Enhanced signal integrity and reduced susceptibility to interference |

| Manufacturing Techniques | Conventional SMT and through-hole mounting | Advanced techniques like HDI, COB, and 3D packaging |

| Applications | Wide range of general-purpose applications | High-performance applications in consumer electronics, automotive, medical, and industrial sectors |

Table 1: Comparison of Traditional PCB Assemblies and Embedded PCB Assemblies

Leave a Reply