Introduction to Custom PCBs

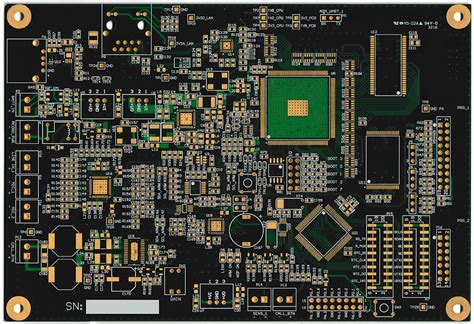

Custom Printed Circuit Boards (PCBs) are specially designed and manufactured boards that are tailored to meet specific electronic requirements. Unlike standard off-the-shelf PCBs, custom PCBs are created to fit the unique needs of a particular application, device, or project. These boards are essential components in various industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.

What are Custom PCBs?

Custom PCBs are printed circuit boards that are designed and manufactured according to specific requirements provided by the client. These requirements can include the board’s size, shape, layer count, material, component placement, and electrical characteristics. By creating a custom PCB, designers and engineers can optimize the board’s performance, reduce its size, and improve its reliability.

Why Use Custom PCBs?

There are several reasons why companies and individuals opt for custom PCBs instead of standard off-the-shelf boards:

-

Unique requirements: When a project has specific electrical, mechanical, or environmental requirements that cannot be met by standard PCBs, custom boards become necessary.

-

Optimization: Custom PCBs allow designers to optimize the board’s layout, component placement, and routing, leading to improved performance, reduced noise, and better signal integrity.

-

Size and shape: Custom boards can be designed to fit into unique enclosures or tight spaces, making them ideal for compact devices or wearable technology.

-

Cost-effectiveness: For large-scale production runs, custom PCBs can be more cost-effective than using multiple standard boards or modifying off-the-shelf components.

Benefits of Custom PCBs

Tailored to Specific Requirements

One of the primary advantages of custom PCBs is that they are designed to meet the specific requirements of a project. This means that the board’s size, shape, layer count, material, and electrical characteristics are all tailored to the needs of the application. By creating a board that is optimized for a particular use case, designers can ensure that the PCB performs reliably and efficiently.

Improved Performance

Custom PCBs allow designers to optimize the board’s layout, component placement, and routing, which can lead to improved performance. By carefully considering factors such as signal integrity, power distribution, and thermal management, designers can create boards that operate at peak efficiency. This can result in faster data transfer rates, reduced noise, and better overall system performance.

Reduced Size and Weight

Another benefit of custom PCBs is that they can be designed to fit into unique enclosures or tight spaces. This is particularly important for applications where size and weight are critical factors, such as in aerospace, medical devices, or wearable technology. By creating a compact and lightweight PCB, designers can reduce the overall size and weight of the device, making it more portable and easier to use.

Cost-Effectiveness for Large-Scale Production

For large-scale production runs, custom PCBs can be more cost-effective than using multiple standard boards or modifying off-the-shelf components. By designing a board that is optimized for a specific application, manufacturers can reduce the number of components required, minimize assembly time, and streamline the production process. This can lead to significant cost savings over the lifecycle of the product.

Enhanced Reliability and Durability

Custom PCBs can be designed with enhanced reliability and durability in mind. By selecting high-quality materials, incorporating redundant circuits, and using robust manufacturing techniques, designers can create boards that are resistant to vibration, shock, and extreme temperatures. This is particularly important for applications that operate in harsh environments, such as industrial equipment or outdoor devices.

Limitations of Custom PCBs

Higher Upfront Costs

One of the main drawbacks of custom PCBs is that they typically have higher upfront costs compared to standard off-the-shelf boards. This is due to the need for specialized design, testing, and manufacturing processes. For small-scale production runs or prototype development, these costs can be prohibitive.

Longer Lead Times

Another limitation of custom PCBs is that they often have longer lead times than standard boards. The design, testing, and manufacturing processes required for custom boards can take several weeks or even months, depending on the complexity of the project. This can be a significant challenge for companies that need to bring products to market quickly.

Requires Specialized Expertise

Designing and manufacturing custom PCBs requires specialized expertise in electrical engineering, PCB layout, and manufacturing processes. This expertise may not be readily available in-house, requiring companies to outsource the design and production of custom boards to specialized firms. This can add to the overall cost and complexity of the project.

Limited Flexibility for Future Modifications

Once a custom PCB has been designed and manufactured, it can be difficult and expensive to make modifications or updates to the board. This is because the board has been optimized for a specific application and may not have the flexibility to accommodate new features or changes in requirements. As a result, companies may need to invest in a new custom board design if their needs change over time.

Applications of Custom PCBs

Custom PCBs are used in a wide range of industries and applications, including:

-

Aerospace: Custom PCBs are essential components in aircraft, satellites, and spacecraft, where reliability, durability, and performance are critical.

-

Automotive: Custom boards are used in various automotive systems, such as engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

-

Medical devices: Custom PCBs are used in medical equipment, such as patient monitors, imaging systems, and implantable devices, where precision and reliability are paramount.

-

Industrial equipment: Custom boards are used in industrial control systems, automation equipment, and monitoring devices, where they must withstand harsh environments and operate reliably.

-

Consumer electronics: Custom PCBs are found in a wide range of consumer devices, such as smartphones, tablets, wearables, and smart home devices, where they enable compact, feature-rich designs.

Designing and Manufacturing Custom PCBs

PCB Design Process

The process of designing a custom PCB involves several key steps:

-

Schematic design: The first step is to create a schematic diagram that represents the electrical connections and components required for the board.

-

Component selection: The next step is to select the appropriate components for the board, based on factors such as performance, cost, and availability.

-

PCB layout: Once the schematic is complete and components are selected, the board layout is created using specialized PCB design software. This involves placing components, routing traces, and defining the board’s physical dimensions.

-

Design review: The completed board design is reviewed by the engineering team to ensure that it meets all requirements and is optimized for manufacturing.

PCB Manufacturing Process

After the design is finalized, the custom PCB is manufactured using the following steps:

-

Fabrication: The PCB is fabricated using a multi-step process that includes printing the circuit pattern, etching the copper layers, and laminating the board with insulating material.

-

Component assembly: The components are then placed on the board using automated pick-and-place machines or manual assembly techniques.

-

Soldering: The components are soldered to the board using reflow ovens or wave soldering machines.

-

Inspection and testing: The completed board is inspected for quality and tested to ensure that it meets all electrical and functional requirements.

Choosing a Custom PCB Manufacturer

When selecting a custom PCB manufacturer, there are several key factors to consider:

-

Experience and expertise: Look for a manufacturer with experience in designing and producing custom PCBs for your specific industry or application.

-

Quality and certifications: Ensure that the manufacturer adheres to industry standards and has relevant certifications, such as ISO 9001 or UL listing.

-

Capabilities: Consider the manufacturer’s capabilities in terms of board complexity, layer count, material options, and component assembly techniques.

-

Lead times and pricing: Compare lead times and pricing among different manufacturers to find the best balance between cost and delivery speed.

-

Customer support: Choose a manufacturer that offers reliable customer support and is responsive to your needs throughout the design and production process.

FAQs

-

Q: What is the difference between a custom PCB and a standard PCB?

A: A custom PCB is designed and manufactured to meet specific requirements for a particular application, while a standard PCB is a pre-designed, off-the-shelf board that is readily available for general use. -

Q: How long does it take to design and manufacture a custom PCB?

A: The lead time for designing and manufacturing a custom PCB can vary depending on the complexity of the board and the manufacturer’s capabilities. Typically, the process can take several weeks to several months. -

Q: Are custom PCBs more expensive than standard PCBs?

A: Yes, custom PCBs typically have higher upfront costs compared to standard PCBs due to the specialized design, testing, and manufacturing processes required. -

Q: What industries commonly use custom PCBs?

A: Custom PCBs are used in a wide range of industries, including aerospace, automotive, medical devices, industrial equipment, and consumer electronics. -

Q: What factors should I consider when choosing a custom PCB manufacturer?

A: When selecting a custom PCB manufacturer, consider factors such as their experience and expertise, quality and certifications, capabilities, lead times and pricing, and customer support.

Conclusion

Custom PCBs offer numerous benefits for applications that require specific electrical, mechanical, or environmental characteristics. By tailoring the board design to meet unique requirements, custom PCBs can improve performance, reduce size and weight, and enhance reliability and durability. However, these benefits come with higher upfront costs, longer lead times, and the need for specialized expertise.

When deciding whether to use a custom PCB for a project, it is essential to carefully consider the specific requirements and weigh the benefits against the limitations. If a custom board is deemed necessary, selecting the right manufacturer is crucial to ensure a successful outcome. By partnering with an experienced and reliable custom PCB manufacturer, companies can bring their innovative ideas to life and create products that meet the demands of their customers.

Leave a Reply