The Significance of Proper PCB Component Orientation

Ensuring Correct Electrical Connections

One of the primary reasons why PCB component orientation is important is to ensure that the components are correctly connected to the circuit board. Each component has specific pins or leads that must be soldered to the appropriate pads or traces on the PCB. If a component is placed incorrectly, it may not make the necessary electrical connections, leading to a malfunctioning or non-functional device.

Proper component orientation is particularly critical for polarized components, such as electrolytic capacitors, diodes, and integrated circuits (ICs). These components have a specific orientation requirement, and placing them incorrectly can cause short circuits, overheating, or permanent damage to the component and the PCB.

Minimizing Signal Interference and Crosstalk

Another crucial aspect of PCB component orientation is its impact on signal integrity. When components are placed too close to each other or oriented in a way that allows for electromagnetic interference (EMI), it can lead to signal degradation, crosstalk, and other unwanted effects.

To minimize signal interference, designers must carefully consider the placement and orientation of components on the PCB. This involves following best practices such as:

- Separating sensitive analog and digital circuits

- Placing decoupling capacitors close to ICs to suppress high-frequency noise

- Orienting inductors and transformers to minimize mutual coupling

- Using ground planes and shielding techniques to reduce EMI

By optimizing component orientation, designers can ensure that signals remain clean and stable, thereby improving the overall performance and reliability of the electronic device.

Thermal Management Considerations

PCB component orientation also plays a vital role in thermal management. Electronic components generate heat during operation, and if this heat is not dissipated effectively, it can lead to performance degradation, reduced lifespan, and even failure of the device.

Proper component orientation can help facilitate heat dissipation by:

- Placing high-power components, such as voltage regulators and power transistors, away from temperature-sensitive components

- Orienting components to allow for adequate airflow and heat dissipation

- Using thermal management techniques, such as heat sinks and thermal vias, to conduct heat away from critical components

By considering thermal management during the component placement and orientation process, designers can ensure that the PCB operates within its specified temperature range, thereby improving its long-term reliability and performance.

Manufacturing Process Optimization

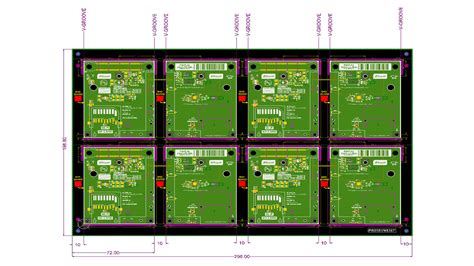

PCB component orientation also has a significant impact on the manufacturing process itself. Proper orientation can help streamline the assembly process, reduce the likelihood of errors, and improve overall production efficiency.

For example, by orienting components in a consistent direction, pick-and-place machines can be programmed to place components more quickly and accurately. This not only reduces the time required for assembly but also minimizes the risk of misplaced components and other assembly defects.

Additionally, proper component orientation can facilitate automated optical inspection (AOI) and other quality control processes. By ensuring that components are oriented correctly and consistently, AOI systems can more easily detect and flag any placement or soldering issues, leading to higher quality control and fewer defects in the final product.

Common PCB Component Orientation Challenges and Solutions

Incorrect Polarity

One of the most common challenges related to PCB component orientation is incorrect polarity. This issue arises when polarized components, such as electrolytic capacitors and diodes, are placed on the PCB with their positive and negative leads reversed.

Incorrect polarity can cause a range of problems, including:

- Short circuits and component damage

- Incorrect voltage levels and signal distortion

- Overheating and potential fire hazards

To avoid polarity issues, designers must ensure that the component footprints on the PCB are clearly marked with the correct polarity indicators, such as plus (+) and minus (-) symbols or notches. Additionally, assembly operators must be trained to recognize and place polarized components correctly, following the markings on the PCB and the component itself.

Inconsistent Orientation

Another common challenge is inconsistent component orientation, which can occur when components are placed on the PCB in different directions or rotations. This can lead to issues such as:

- Difficulty in automated assembly processes

- Increased likelihood of placement errors

- Aesthetically unappealing and unprofessional-looking PCBs

To address this challenge, designers should establish and adhere to a consistent component orientation scheme throughout the PCB layout process. This may involve aligning components in a specific direction (e.g., all resistors oriented vertically) or ensuring that similar components are oriented in the same direction across the board.

Consistency in component orientation not only improves the efficiency of the assembly process but also makes the PCB easier to inspect, troubleshoot, and repair if necessary.

Clearance and Spacing Issues

PCB component orientation can also be affected by clearance and spacing issues, which occur when components are placed too close to each other or to the edge of the board. This can cause problems such as:

- Difficulty in soldering and assembly

- Increased risk of short circuits and signal interference

- Limited access for testing and repair

To avoid clearance and spacing issues, designers must adhere to the minimum clearance and spacing requirements specified by the PCB manufacturing process and the components themselves. This may involve adjusting component placement, using smaller component packages, or increasing the overall size of the PCB to accommodate the necessary spacing.

In some cases, designers may also need to use specialized PCB layout techniques, such as staggered placement or component grouping, to optimize space utilization while maintaining proper clearance and spacing.

Best Practices for Optimizing PCB Component Orientation

To ensure optimal PCB component orientation and avoid potential issues, designers should follow these best practices:

-

Use consistent orientation schemes: Establish and maintain a consistent component orientation scheme throughout the PCB layout process, aligning components in a specific direction or ensuring that similar components are oriented in the same direction across the board.

-

Follow manufacturer guidelines: Adhere to the manufacturer’s recommended orientation and placement guidelines for each component, paying particular attention to polarized components and those with specific thermal management requirements.

-

Consider assembly processes: Design the PCB layout with the assembly process in mind, orienting components in a way that facilitates automated placement and minimizes the risk of placement errors.

-

Optimize for signal integrity: Place and orient components to minimize signal interference and crosstalk, following best practices such as separating sensitive circuits, using decoupling capacitors, and implementing shielding techniques.

-

Address thermal management: Consider thermal management during component placement and orientation, placing high-power components away from temperature-sensitive ones and orienting components to allow for adequate heat dissipation.

-

Adhere to clearance and spacing requirements: Follow the minimum clearance and spacing requirements specified by the PCB manufacturing process and the components themselves, adjusting component placement or using specialized layout techniques as necessary.

-

Utilize PCB design software: Leverage the capabilities of modern PCB design software to automate and optimize component placement and orientation, using features such as design rule checks (DRC), component libraries, and auto-placement tools.

By following these best practices, designers can create PCB layouts that are optimized for performance, reliability, and manufacturability, while minimizing the risk of orientation-related issues.

Frequently Asked Questions (FAQ)

-

What is PCB component orientation?

PCB component orientation refers to the placement and alignment of components on a printed circuit board (PCB) in relation to the board itself and other components. -

Why is PCB component orientation important?

Proper PCB component orientation is crucial for ensuring correct electrical connections, minimizing signal interference and crosstalk, optimizing thermal management, and facilitating efficient manufacturing processes. -

What are some common issues related to PCB component orientation?

Common issues related to PCB component orientation include incorrect polarity, inconsistent orientation, and clearance and spacing problems. -

How can designers avoid polarity issues in PCB component orientation?

To avoid polarity issues, designers should ensure that component footprints on the PCB are clearly marked with the correct polarity indicators and that assembly operators are trained to recognize and place polarized components correctly. -

What are some best practices for optimizing PCB component orientation?

Best practices for optimizing PCB component orientation include using consistent orientation schemes, following manufacturer guidelines, considering assembly processes, optimizing for signal integrity, addressing thermal management, adhering to clearance and spacing requirements, and utilizing PCB design software.

Conclusion

PCB component orientation is a critical aspect of circuit board manufacturing that directly impacts the performance, reliability, and manufacturability of electronic devices. By understanding the importance of proper component placement and alignment, designers can create PCB layouts that are optimized for electrical connectivity, signal integrity, thermal management, and efficient assembly processes.

To achieve optimal PCB component orientation, designers must follow best practices such as establishing consistent orientation schemes, adhering to manufacturer guidelines, considering assembly processes, and addressing potential issues related to polarity, clearance, and spacing. By leveraging the capabilities of modern PCB design software and collaborating closely with manufacturing partners, designers can ensure that their PCBs are built to the highest standards of quality and reliability.

As the electronics industry continues to evolve and demand increasingly complex and high-performance devices, the importance of PCB component orientation will only continue to grow. By staying up-to-date with the latest techniques and best practices in PCB design and manufacturing, engineers and designers can create innovative and reliable electronic products that meet the needs of today’s rapidly changing market.

Leave a Reply