Introduction

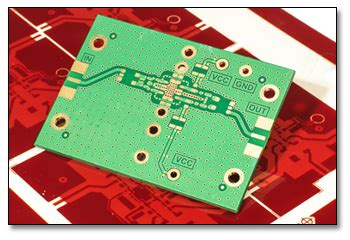

Printed Circuit Board (PCB) prototyping is a crucial step in the electronics manufacturing process. It allows designers and engineers to test and validate their designs before mass production. However, the success of PCB Prototyping heavily depends on the accuracy and completeness of the Bill of Materials (BOM). In this article, we will discuss why optimizing the BOM is essential for rapid PCB prototyping and how it can help streamline the entire process.

What is a Bill of Materials?

A Bill of Materials (BOM) is a comprehensive list of all the components, materials, and quantities required to manufacture a product. In the context of PCB prototyping, a BOM includes all the electronic components, connectors, and hardware needed to assemble the PCB.

Components of a BOM

A typical BOM for PCB prototyping includes the following components:

- Component name

- Manufacturer part number

- Quantity

- Description

- Package type

- Reference designator

- Supplier information

| Component Name | Manufacturer Part Number | Quantity | Description | Package Type | Reference Designator | Supplier |

|---|---|---|---|---|---|---|

| Resistor | ABC123 | 10 | 10K Ohm | 0805 | R1-R10 | XYZ Inc. |

| Capacitor | DEF456 | 5 | 10uF | 1206 | C1-C5 | XYZ Inc. |

Importance of Accurate BOM in PCB Prototyping

1. Ensures All Components are Available

An accurate BOM ensures that all the necessary components are available for PCB assembly. Missing components can delay the prototyping process and increase costs.

2. Avoids Compatibility Issues

An optimized BOM helps avoid compatibility issues between components. Using incorrect or incompatible components can lead to functional problems and delays in the prototyping process.

3. Facilitates Smooth Communication

A well-organized BOM facilitates smooth communication between the design team, procurement team, and the PCB assembly provider. It reduces the chances of misinterpretation and errors.

Best Practices for Optimizing BOM

1. Use a Consistent Format

Using a consistent format for the BOM helps ensure that all the necessary information is included and easily understandable by all stakeholders.

2. Include Detailed Component Information

Providing detailed component information, such as manufacturer part numbers and package types, helps avoid ambiguity and ensures the correct components are used.

3. Verify Component Availability

Verifying the availability of components before finalizing the BOM helps avoid delays due to out-of-stock or obsolete components.

4. Use a Component Library

Using a component library helps standardize the component selection process and ensures that the chosen components are compatible and readily available.

Benefits of Optimizing BOM for PCB Prototyping

1. Faster Turnaround Time

An optimized BOM helps reduce the turnaround time for PCB prototyping by ensuring that all the necessary components are readily available and compatible.

2. Cost Savings

An accurate BOM helps avoid unnecessary component purchases and reduces the chances of assembly errors, leading to cost savings.

3. Improved Design Reliability

Using compatible and readily available components improves the overall reliability of the PCB design.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a BOM and a schematic?

A: A schematic is a graphical representation of the electronic circuit, while a BOM is a list of all the components required to assemble the PCB. -

Q: Can I use a spreadsheet to create a BOM?

A: Yes, spreadsheets are commonly used to create BOMs. However, ensure that the spreadsheet includes all the necessary information and follows a consistent format. -

Q: How do I ensure component compatibility in my BOM?

A: To ensure component compatibility, refer to the manufacturer’s datasheets and application notes. Also, consider using a component library that includes pre-verified components. -

Q: What should I do if a component in my BOM becomes obsolete?

A: If a component becomes obsolete, look for a suitable alternative that meets the same specifications and is readily available. Update the BOM accordingly. -

Q: How often should I review and update my BOM?

A: It’s good practice to review and update your BOM regularly, especially if there are changes in the component availability or specifications. Regularly updating the BOM helps ensure its accuracy and relevance.

Conclusion

Optimizing the Bill of Materials is crucial for rapid PCB prototyping. An accurate and well-organized BOM ensures that all the necessary components are available, compatible, and easily understandable by all stakeholders. By following best practices and regularly reviewing and updating the BOM, designers and engineers can streamline the PCB prototyping process, reduce turnaround times, and save costs. Investing time in creating and maintaining an optimized BOM pays off in the long run by improving the overall efficiency and reliability of the PCB prototyping process.

Leave a Reply