Introduction to Prototype PCB Boards

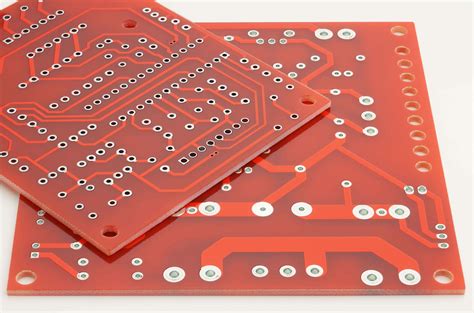

Prototype PCB (Printed Circuit Board) boards are essential components in the electronics industry, enabling designers and engineers to test and validate their circuit designs before mass production. These boards play a crucial role in the development process, allowing for the identification and correction of any issues or improvements needed in the circuit design.

What is a Prototype PCB?

A prototype PCB is a preliminary version of a printed circuit board that is used for testing and validation purposes. It is a physical representation of the circuit design, which includes all the necessary components, such as resistors, capacitors, and integrated circuits (ICs), mounted on a non-conductive substrate.

Why are Prototype PCBs Important?

Prototype PCBs are essential for several reasons:

-

Design Validation: Prototype PCBs allow designers to test their circuit designs in a real-world environment, ensuring that the circuit functions as intended.

-

Error Detection: By testing the prototype PCB, designers can identify any errors or issues in the circuit design, such as short circuits, open circuits, or incorrect component placement.

-

Cost-Effective: Prototype PCBs are a cost-effective way to test and validate circuit designs before investing in mass production, reducing the risk of costly mistakes.

-

Time-Saving: Using prototype PCBs can save time in the development process by allowing designers to quickly test and iterate on their designs.

Factors to Consider When Buying Prototype PCB Boards

When purchasing prototype PCB boards, there are several factors to consider to ensure that you get the best quality boards for your needs.

1. Material Quality

The quality of the materials used in the manufacture of prototype PCB boards is crucial. High-quality materials ensure that the boards are durable, reliable, and have good electrical properties.

The most common materials used for prototype PCB boards are:

| Material | Description |

|---|---|

| FR-4 | A glass-reinforced epoxy laminate that is the most widely used material for PCBs. It has good mechanical and electrical properties and is suitable for most applications. |

| Polyimide | A high-performance material that is resistant to high temperatures and chemicals. It is often used in aerospace and military applications. |

| Aluminum | A metal-based PCB material that is used for high-power applications, such as LED lighting and motor controllers. |

2. Manufacturing Process

The manufacturing process used to create prototype PCB boards can have a significant impact on the quality and reliability of the final product.

Some of the most common manufacturing processes include:

| Process | Description |

|---|---|

| Etching | A chemical process that removes unwanted copper from the PCB substrate, leaving only the desired circuit pattern. |

| Drilling | The process of creating holes in the PCB for through-hole components and vias. |

| Plating | The process of applying a thin layer of metal, such as gold or silver, to the PCB to improve conductivity and prevent oxidation. |

| Solder Mask | A protective layer applied to the PCB to prevent short circuits and improve the board’s appearance. |

| Silkscreen | The process of printing text and symbols on the PCB for identification and assembly purposes. |

3. Lead Time

Lead time is the time it takes for a manufacturer to produce and deliver your prototype PCB boards. When choosing a manufacturer, it is essential to consider their lead times and whether they can meet your project deadlines.

Some manufacturers offer expedited services for an additional fee, which can be useful if you have tight deadlines.

4. Cost

The cost of prototype PCB boards can vary significantly depending on the manufacturer, material, and complexity of the design.

When comparing prices, it is essential to consider the total cost of ownership, which includes not only the cost of the boards themselves but also any additional services, such as assembly or testing.

Some manufacturers offer discounts for bulk orders or repeat business, so it is worth considering your long-term needs when choosing a supplier.

5. Customer Support

Good customer support is essential when buying prototype PCB boards, especially if you are new to the process or have complex requirements.

Look for manufacturers that offer responsive and knowledgeable support, with multiple channels of communication, such as email, phone, and live chat.

Some manufacturers also offer design assistance or review services, which can be helpful in ensuring that your design is optimized for manufacturability and reliability.

Benefits of Using Prototype PCB Boards

Using prototype PCB boards offers several benefits for designers and engineers.

1. Improved Design Quality

By testing and validating your circuit design with a prototype PCB, you can identify and correct any issues early in the development process, improving the overall quality of your design.

Prototype PCBs allow you to test your design in a real-world environment, which can reveal issues that may not be apparent in simulation or on breadboards.

2. Reduced Development Time

Using prototype PCB boards can significantly reduce the development time for your project.

By testing and iterating on your design quickly, you can avoid costly delays and get your product to market faster.

Prototype PCBs also allow you to test and validate your design in parallel with other development activities, such as software development or mechanical design.

3. Cost Savings

Using prototype PCB boards can save you money in the long run by reducing the risk of costly mistakes or redesigns.

By testing and validating your design early in the development process, you can avoid the expense of producing a large batch of boards that may not work as intended.

Prototype PCBs also allow you to optimize your design for manufacturability, which can reduce production costs and improve yield.

4. Improved Communication

Prototype PCB boards can serve as a valuable communication tool between different teams or stakeholders in your project.

By having a physical representation of your circuit design, you can easily demonstrate how your product works and get feedback from others.

Prototype PCBs can also help to bridge the gap between the abstract world of circuit design and the tangible world of physical products.

Choosing the Right Prototype PCB Manufacturer

Choosing the right prototype PCB manufacturer is essential for ensuring the success of your project.

Here are some factors to consider when selecting a manufacturer:

1. Experience and Expertise

Look for a manufacturer with experience and expertise in producing prototype PCB boards for your specific industry or application.

Manufacturers with specialized knowledge can offer valuable insights and advice on how to optimize your design for manufacturability and reliability.

2. Quality Control

Quality control is essential for ensuring that your prototype PCB boards meet your specifications and performance requirements.

Look for manufacturers that have robust quality control processes in place, such as automated optical inspection (AOI) or X-ray inspection.

Some manufacturers also offer additional quality assurance services, such as electrical testing or burn-in testing.

3. Certifications and Standards

Ensure that your chosen manufacturer complies with relevant industry certifications and standards, such as ISO 9001 for quality management or UL 94 for flammability.

Compliance with these standards ensures that your prototype PCB boards are produced to a high level of quality and safety.

4. Flexibility and Customization

Look for a manufacturer that offers flexibility and customization options to meet your specific needs.

Some manufacturers offer a range of different materials, finishes, and features, such as blind or buried vias, controlled impedance, or flex-rigid designs.

Flexibility and customization can be particularly important for complex or specialized designs.

5. Reputation and Reviews

Finally, consider the reputation and reviews of potential manufacturers before making your decision.

Look for manufacturers with positive reviews and testimonials from previous customers, particularly those in your industry or with similar requirements.

You can also ask for references or case studies to get a better understanding of the manufacturer’s capabilities and customer service.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity for prototype PCB boards?

The minimum order quantity for prototype PCB boards varies depending on the manufacturer and the complexity of your design. Some manufacturers offer low minimum order quantities, such as 5 or 10 boards, while others may require a minimum order of 100 or more boards.

2. How long does it take to produce prototype PCB boards?

The lead time for producing prototype PCB boards depends on several factors, such as the complexity of your design, the materials used, and the manufacturing process. Typical lead times range from a few days to several weeks, depending on the manufacturer and the specific requirements of your project.

3. Can I get assembly services for my prototype PCB boards?

Yes, many prototype PCB manufacturers offer assembly services in addition to board fabrication. Assembly services can include component sourcing, placement, and soldering, as well as testing and inspection. Some manufacturers offer turnkey assembly services, where they handle the entire process from design to finished product.

4. What file formats do I need to provide for prototype PCB fabrication?

The file formats required for prototype PCB fabrication vary depending on the manufacturer and the design software used. Common file formats include Gerber files, which are industry-standard files that describe the layout of the PCB layers, as well as drill files, which specify the location and size of holes in the board. Some manufacturers may also accept other file formats, such as ODB++ or IPC-2581.

5. Can I get a discount for ordering larger quantities of prototype PCB boards?

Yes, many prototype PCB manufacturers offer volume discounts for larger orders. The specific discount structure varies depending on the manufacturer and the quantity ordered, but typical discounts range from 10% to 50% for orders of 100 boards or more. Some manufacturers also offer additional discounts for repeat orders or long-term contracts.

Conclusion

Prototype PCB boards are an essential tool for designers and engineers looking to test and validate their circuit designs before moving to mass production. When choosing a prototype PCB manufacturer, it is important to consider factors such as material quality, manufacturing process, lead time, cost, and customer support.

Using prototype PCB boards offers several benefits, including improved design quality, reduced development time, cost savings, and improved communication between teams and stakeholders.

By selecting the right prototype PCB manufacturer and leveraging the benefits of prototype PCBs, designers and engineers can bring their products to market faster, with higher quality and reliability.

Leave a Reply