What is PCB Electrical Testing?

PCB electrical testing is the process of verifying the electrical continuity, isolation, and functionality of a printed circuit board. The primary goal of electrical testing is to identify any defects or issues in the PCB that may affect its performance or reliability. Electrical testing is performed at various stages of the manufacturing process, from the bare board to the fully assembled PCB.

Importance of PCB Electrical Testing

Electrical testing is crucial in PCB manufacturing for several reasons:

-

Quality Assurance: Electrical testing helps ensure that the PCB meets the required quality standards and specifications. It identifies any defects or issues that may compromise the board’s performance or reliability.

-

Cost Savings: Identifying defects early in the manufacturing process can save significant costs associated with rework, repair, or replacement of faulty boards.

-

Reliability: Thorough electrical testing ensures that the PCB will function reliably in its intended application, reducing the risk of failures or malfunctions in the field.

-

Compliance: Electrical testing helps verify that the PCB complies with industry standards and regulations, such as IPC (Association Connecting Electronics Industries) and UL (Underwriters Laboratories).

Types of PCB Electrical Testing

There are several types of electrical testing performed on PCBs, depending on the stage of manufacturing and the specific requirements of the board. Some of the common types of PCB electrical testing include:

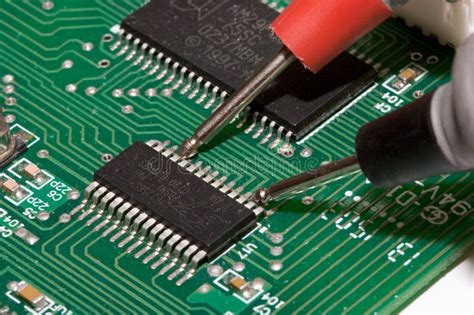

1. Continuity Testing

Continuity testing is performed to verify that all the intended connections on the PCB are intact and that there are no open circuits. This test is typically performed using a multimeter or a dedicated continuity tester. The test probes are placed on the relevant points on the PCB, and the resistance between them is measured. If the resistance is within the acceptable range, the connection is considered good.

2. Isolation Testing

Isolation testing, also known as insulation resistance testing, is performed to ensure that there are no unintended short circuits or leakage paths between different conductors on the PCB. This test is crucial to prevent signal interference, crosstalk, and potential safety hazards. Isolation testing is typically performed using a high-voltage insulation tester, which applies a specified voltage between the conductors and measures the resistance.

3. Functional Testing

Functional testing is performed to verify that the PCB functions as intended and meets the required specifications. This test involves applying power to the board and testing its various features and functions, such as input/output signals, communication interfaces, and power management. Functional testing may require specialized test equipment, such as oscilloscopes, logic analyzers, and signal generators.

4. In-Circuit Testing (ICT)

In-circuit testing is a method of testing individual components on the PCB to ensure that they are correctly installed and functioning as expected. ICT is performed using a bed-of-nails fixture, which makes contact with the relevant test points on the PCB. The test system then applies a series of electrical tests to each component, such as resistance, capacitance, and diode tests. ICT is highly automated and can quickly identify faulty components.

5. Flying Probe Testing

Flying probe testing is an alternative to ICT for low-volume or prototype PCBs. Instead of using a bed-of-nails fixture, flying probe testing uses movable test probes that can access any point on the PCB. The test system moves the probes to the relevant test points and performs the required electrical tests. Flying probe testing is more flexible than ICT but is slower and less suitable for high-volume production.

6. Boundary Scan Testing

Boundary scan testing, also known as JTAG (Joint Test Action Group) testing, is a method of testing complex digital circuits on the PCB. Boundary scan testing uses a special test access port (TAP) on the PCB, which allows the test system to access and control the individual pins of the integrated circuits. This enables testing of the interconnections between the ICs and the PCB, as well as the functionality of the ICs themselves.

PCB Electrical Testing Equipment

To perform PCB electrical testing, various types of test equipment are used, depending on the specific requirements of the board and the type of testing being performed. Some of the common PCB electrical testing equipment includes:

| Equipment | Description |

|---|---|

| Multimeter | A basic tool used for measuring voltage, current, and resistance. Multimeters are commonly used for continuity testing. |

| Insulation Tester | A high-voltage tester used for measuring the insulation resistance between conductors on the PCB. |

| Oscilloscope | A test instrument that displays and analyzes waveforms. Oscilloscopes are used for functional testing and debugging. |

| Logic Analyzer | A device that captures and displays digital signals. Logic analyzers are used for functional testing and debugging of digital circuits. |

| Signal Generator | A test instrument that generates various types of electrical signals. Signal generators are used for functional testing and simulating input signals. |

| In-Circuit Tester (ICT) | An automated test system that uses a bed-of-nails fixture to test individual components on the PCB. |

| Flying Probe Tester | An automated test system that uses movable test probes to access and test any point on the PCB. |

| Boundary Scan Tester | A test system that uses a special test access port (TAP) to control and test the individual pins of the integrated circuits on the PCB. |

PCB Electrical Testing Standards

PCB electrical testing is governed by various industry standards and guidelines to ensure consistency, reliability, and compliance. Some of the key standards related to PCB electrical testing include:

-

IPC-9252A: This standard provides guidelines for electrical testing of unpopulated printed boards. It covers continuity, isolation, and resistance testing.

-

IPC-9701A: This standard provides guidelines for performance testing of single- and double-sided printed boards. It covers test methods, equipment, and acceptance criteria.

-

IPC-TM-650: This is a collection of test methods for printed boards and printed board materials. It includes several electrical testing methods, such as insulation resistance, continuity, and dielectric withstanding voltage.

-

IPC-A-610: This standard provides acceptance criteria for electronic assemblies, including PCBs. It includes guidelines for visual inspection and electrical testing.

-

UL-796: This is a safety standard for printed wiring boards, which includes requirements for electrical testing, such as dielectric withstanding voltage and insulation resistance.

Best Practices for PCB Electrical Testing

To ensure effective and reliable PCB electrical testing, consider the following best practices:

-

Develop a comprehensive test plan: Define the specific test requirements, test methods, and acceptance criteria for each stage of the manufacturing process.

-

Use appropriate test equipment: Select the right test equipment based on the specific requirements of the PCB and the type of testing being performed. Ensure that the equipment is calibrated and maintained regularly.

-

Follow industry standards: Adhere to the relevant industry standards and guidelines for PCB electrical testing to ensure consistency, reliability, and compliance.

-

Perform testing at various stages: Conduct electrical testing at various stages of the manufacturing process, from the bare board to the fully assembled PCB, to identify defects early and reduce rework costs.

-

Document test results: Maintain detailed records of the test results, including any defects or issues found, corrective actions taken, and final acceptance status.

-

Continuously improve: Analyze test data and trends to identify opportunities for process improvement and optimization. Continuously monitor and update test methods and equipment to keep pace with technological advancements.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between continuity testing and isolation testing?

A: Continuity testing verifies that all the intended connections on the PCB are intact and that there are no open circuits. Isolation testing, on the other hand, ensures that there are no unintended short circuits or leakage paths between different conductors on the PCB. -

Q: What is the purpose of functional testing in PCB manufacturing?

A: Functional testing is performed to verify that the PCB functions as intended and meets the required specifications. It involves applying power to the board and testing its various features and functions, such as input/output signals, communication interfaces, and power management. -

Q: What are the advantages of in-circuit testing (ICT) compared to other testing methods?

A: In-circuit testing (ICT) is highly automated and can quickly identify faulty components on the PCB. It tests individual components using a bed-of-nails fixture, which makes contact with the relevant test points on the PCB. ICT is suitable for high-volume production and can significantly reduce test time and costs. -

Q: When is flying probe testing preferred over in-circuit testing (ICT)?

A: Flying probe testing is preferred over ICT for low-volume or prototype PCBs, where the cost of developing a dedicated bed-of-nails fixture is not justified. Flying probe testing uses movable test probes that can access any point on the PCB, making it more flexible than ICT. -

Q: What is the role of industry standards in PCB electrical testing?

A: Industry standards, such as IPC and UL, provide guidelines and requirements for PCB electrical testing to ensure consistency, reliability, and compliance. These standards cover various aspects of testing, including test methods, equipment, and acceptance criteria. Adhering to industry standards helps ensure the quality and safety of the PCBs.

In conclusion, PCB electrical testing is a critical aspect of PCB manufacturing that ensures the quality, reliability, and functionality of the final product. By understanding the various types of electrical testing, the equipment used, and the best practices, manufacturers can optimize their testing processes and deliver high-quality PCBs that meet the required specifications and standards. As technology advances and PCBs become more complex, the importance of comprehensive and effective electrical testing will only continue to grow.

Leave a Reply