Introduction to Flying Probe Testing

Flying probe testing is a advanced method of electrical testing that has revolutionized the way printed circuit boards (PCBs) are tested for functionality and quality. Unlike traditional fixture-based testing, which requires a custom-designed test fixture for each unique PCB design, flying probe testing utilizes movable test probes that can be programmed to test any point on a PCB without the need for a dedicated fixture.

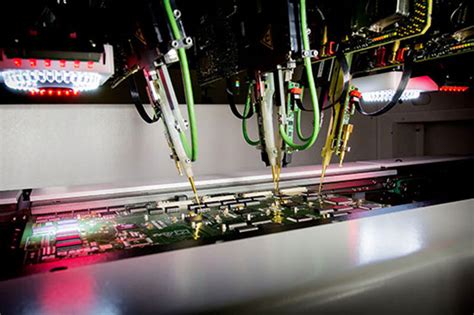

How Flying Probe Testing Works

The flying probe testing process involves the use of several precision-guided probes that move across the surface of the PCB, making contact with specific test points to perform electrical measurements. These probes are typically mounted on a high-speed, high-precision XYZ positioning system that allows them to quickly and accurately navigate the PCB surface.

The number of probes used in a flying probe tester can vary depending on the specific machine and the complexity of the PCB being tested. Most modern flying probe testers employ between 4 and 8 probes, although some high-end systems may use even more.

Each probe is capable of performing a variety of electrical measurements, including:

- Continuity testing

- Resistance measurement

- Capacitance measurement

- Inductance measurement

- Diode and transistor testing

The specific tests performed on a given PCB are determined by the test program, which is created using specialized software and loaded into the flying probe machine prior to testing.

Advantages of Flying Probe Testing

Flying probe testing offers several key advantages over traditional fixture-based testing methods:

-

Flexibility: Because flying probe testers don’t require custom test fixtures, they can easily adapt to changes in PCB design without the need for costly and time-consuming fixture modifications.

-

Cost savings: Eliminating the need for custom test fixtures can significantly reduce the overall cost of PCB testing, particularly for low-volume production runs or prototype designs.

-

Improved test coverage: Flying probe testers can access and test points on a PCB that may be difficult or impossible to reach with a traditional test fixture, resulting in improved test coverage and higher fault detection rates.

-

Faster setup times: Programming a flying probe tester for a new PCB design is generally much faster than designing and fabricating a custom test fixture, which can help reduce overall development times and speed time-to-market.

Applications of Flying Probe Testing

Flying probe testing is widely used across a variety of industries and applications, including:

- Aerospace and defense

- Automotive electronics

- Medical devices

- Consumer electronics

- Industrial control systems

- Telecommunications equipment

In general, flying probe testing is particularly well-suited for the following types of PCB testing scenarios:

Prototype Testing

During the prototype phase of PCB development, designs often undergo frequent changes and iterations. Flying probe testing allows designers to quickly and easily test each new prototype version without the need for custom test fixtures, helping to speed up the development process and reduce overall prototyping costs.

Low-Volume Production

For low-volume production runs, the cost of designing and fabricating custom test fixtures can be prohibitively expensive. Flying probe testing provides a cost-effective alternative that allows manufacturers to thoroughly test their PCBs without the need for dedicated fixtures.

High-Mix Manufacturing

In high-mix manufacturing environments, where a wide variety of PCB designs are produced in relatively low volumes, flying probe testing can provide a flexible and efficient testing solution that can adapt quickly to changing product mix and design requirements.

Limitations of Flying Probe Testing

Despite its many advantages, flying probe testing does have some limitations that should be considered:

-

Testing speed: Flying probe testing is generally slower than traditional fixture-based testing, particularly for high-volume production runs. This is due to the time required for the probes to move between test points on the PCB.

-

Limited test access: While flying probe testers can access many points on a PCB that traditional fixtures cannot, there may still be some areas of the board that are inaccessible due to component placement or other design factors.

-

Reduced mechanical stress testing: Flying probe testers are not well-suited for applying mechanical stress to components during testing, which can be important for detecting certain types of faults or ensuring the durability of the PCB assembly.

Choosing a Flying Probe Tester

When selecting a flying probe tester for your specific application, there are several key factors to consider:

-

Number of probes: The number of probes available on the tester will impact its overall testing speed and capability. Choose a system with enough probes to meet your current and anticipated future testing needs.

-

Probe accuracy and repeatability: Look for a system with high probe placement accuracy and repeatability to ensure reliable and consistent test results.

-

Software capabilities: The software used to program and control the flying probe tester should be user-friendly, flexible, and capable of supporting your specific testing requirements.

-

Machine reliability and maintenance: Consider the overall reliability and maintainability of the flying probe tester, including factors such as machine uptime, ease of maintenance, and availability of spare parts and support.

-

Cost: Flying probe testers can vary widely in price depending on their capabilities and features. Consider your budget constraints and the expected return on investment when selecting a system.

Best Practices for Implementing Flying Probe Testing

To ensure successful implementation of flying probe testing in your PCB manufacturing process, consider the following best practices:

-

Optimize PCB design for testability: Design your PCBs with testing in mind, incorporating features such as test points, clear probe access, and minimized component density where possible.

-

Develop comprehensive test plans: Create detailed test plans that specify the specific measurements and tests to be performed on each PCB, as well as the acceptable range of results for each test.

-

Regularly calibrate and maintain equipment: Ensure that your flying probe tester is regularly calibrated and maintained according to the manufacturer’s recommended schedule to ensure accurate and reliable test results.

-

Train personnel: Provide thorough training to all personnel involved in the flying probe testing process, including machine operators, test engineers, and quality control staff.

-

Monitor and analyze test results: Regularly monitor and analyze the results of your flying probe tests to identify trends, detect potential issues, and continuously improve your testing process.

The Future of Flying Probe Testing

As PCB designs continue to become more complex and miniaturized, the demand for flexible, high-precision testing solutions like flying probe testing is likely to continue to grow. Some of the key trends and developments that are likely to shape the future of flying probe testing include:

-

Increased probe density: As PCBs become more densely populated with components, flying probe testers will need to incorporate a greater number of probes and more precise positioning systems to ensure adequate test coverage.

-

Improved speed and accuracy: Advances in probe technology, positioning systems, and control software will enable flying probe testers to operate at even higher speeds and with greater accuracy than is currently possible.

-

Integration with other testing methods: Flying probe testing may be increasingly combined with other testing methods, such as boundary scan or functional testing, to provide a more comprehensive and efficient testing solution.

-

Automated test program generation: The development of advanced software tools that can automatically generate optimized test programs based on PCB design data could significantly streamline the flying probe testing process and reduce the need for manual test program development.

-

Application-specific testers: The development of specialized flying probe testers optimized for specific industries or applications, such as automotive or aerospace, could help to further improve testing efficiency and effectiveness in these sectors.

Frequently Asked Questions (FAQ)

-

What is flying probe testing?

Flying probe testing is an advanced method of electrical testing that uses movable test probes to perform electrical measurements on a printed circuit board (PCB) without the need for a custom test fixture. -

How does flying probe testing differ from traditional fixture-based testing?

Traditional fixture-based testing requires a custom-designed test fixture for each unique PCB design, while flying probe testing uses programmable test probes that can adapt to any PCB design without the need for a dedicated fixture. -

What types of electrical measurements can a flying probe tester perform?

A flying probe tester can perform a variety of electrical measurements, including continuity testing, resistance measurement, capacitance measurement, inductance measurement, and diode and transistor testing. -

What are the main advantages of flying probe testing?

The main advantages of flying probe testing include flexibility, cost savings, improved test coverage, and faster setup times compared to traditional fixture-based testing methods. -

What factors should be considered when selecting a flying probe tester?

When selecting a flying probe tester, key factors to consider include the number of probes, probe accuracy and repeatability, software capabilities, machine reliability and maintenance, and cost.

Conclusion

Flying probe testing has emerged as a powerful and versatile solution for electrical testing of PCBs, offering numerous advantages over traditional fixture-based testing methods. By providing greater flexibility, improved test coverage, and reduced setup times and costs, flying probe testing has become an essential tool for manufacturers across a wide range of industries.

As PCB designs continue to evolve and become more complex, the importance of flying probe testing is likely to only grow in the coming years. By staying abreast of the latest developments in flying probe technology and following best practices for implementation, manufacturers can ensure that they are well-positioned to meet the testing challenges of the future and deliver high-quality, reliable products to their customers.

| Characteristic | Flying Probe Testing | Fixture-Based Testing |

|---|---|---|

| Test fixture required | No | Yes |

| Setup time | Fast | Slow |

| Adaptability to design changes | High | Low |

| Test coverage | High | Moderate |

| Testing speed | Moderate | Fast |

| Cost for low-volume production | Low | High |

| Mechanical stress testing | Limited | Capable |

This table provides a side-by-side comparison of the key characteristics of flying probe testing and traditional fixture-based testing, highlighting the relative strengths and weaknesses of each approach.

Leave a Reply