Introduction to PCB Quality

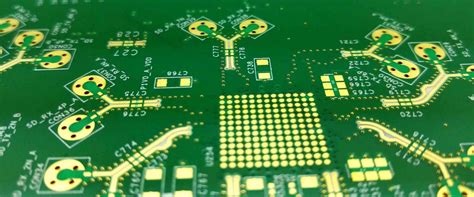

Printed Circuit Boards (PCBs) are essential components in modern electronic devices. With China being a major player in the global PCB manufacturing industry, it’s crucial to understand how to differentiate between high-quality and low-quality PCBs sourced from Chinese manufacturers. In this article, we will explore the key factors that contribute to PCB quality and provide guidance on how to identify and select reliable Chinese PCB suppliers.

Factors Affecting PCB Quality

1. Material Selection

The choice of materials used in PCB fabrication plays a significant role in determining the overall quality and reliability of the end product. High-quality PCBs use premium materials such as FR-4, Rogers, or Polyimide substrates, depending on the specific application requirements. Low-quality PCBs often use inferior materials that may compromise the board’s performance and longevity.

2. Manufacturing Process

The manufacturing process employed by the PCB supplier directly impacts the quality of the final product. A well-controlled and optimized process ensures consistent quality and minimizes defects. Look for suppliers that adhere to industry standards such as IPC-A-600 and have strict quality control measures in place.

2.1 Copper Thickness and Trace Width

The copper thickness and trace width are critical parameters in PCB design and manufacturing. Insufficient copper thickness or overly narrow traces can lead to signal integrity issues, increased resistance, and reduced current-carrying capacity. Ensure that the supplier follows the specified design guidelines and maintains appropriate copper thickness and Trace Width Tolerances.

| Copper Weight (oz) | Thickness (μm) |

|---|---|

| 0.5 | 17.5 |

| 1 | 35 |

| 2 | 70 |

| 3 | 105 |

3. Surface Finish

The surface finish of a PCB serves both functional and aesthetic purposes. Common surface finishes include Hot Air Solder Leveling (HASL), Immersion Silver, Immersion Tin, and Electroless Nickel Immersion Gold (ENIG). Each surface finish has its advantages and limitations. Choose a surface finish that suits your application requirements and ensures good solderability and long-term reliability.

4. Solder Mask and Silkscreen Quality

The solder mask and silkscreen layers on a PCB provide insulation, protection, and labeling. A high-quality solder mask should be even, uniform, and free from defects such as pinholes or blistering. The silkscreen should be clear, legible, and accurately aligned with the underlying features. Poor solder mask and silkscreen quality can lead to assembly issues and compromise the overall functionality of the PCB.

Identifying Reliable Chinese PCB Suppliers

1. Certifications and Standards Compliance

When searching for a reliable Chinese PCB supplier, look for companies that hold relevant certifications and comply with industry standards. Some important certifications to consider include:

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management System

- UL (Underwriters Laboratories) certification

- IPC (Association Connecting Electronics Industries) standards compliance

2. Manufacturing Capabilities and Technology

Assess the manufacturing capabilities and technology of potential PCB suppliers. A reliable supplier should have state-of-the-art equipment, automated processes, and the ability to handle a wide range of PCB types and complexity levels. Inquire about their experience with different PCB technologies such as multi-layer boards, high-density interconnects (HDI), and flexible or rigid-flex PCBs.

3. Quality Control and Testing

A reputable PCB supplier should have robust quality control measures and testing procedures in place. Ask about their quality control process, including incoming material inspection, in-process checks, and final product testing. They should utilize advanced testing equipment such as automated optical inspection (AOI), X-ray inspection, and electrical testing to ensure the quality and functionality of the PCBs.

4. Customer Support and Communication

Effective communication and responsive customer support are essential when working with a Chinese PCB supplier. Look for suppliers that have a dedicated sales team, technical support, and a streamlined communication process. They should be able to provide timely responses to your inquiries, offer design assistance, and address any issues or concerns promptly.

Frequently Asked Questions (FAQ)

1. How can I verify the quality of PCBs from a Chinese supplier?

To verify the quality of PCBs from a Chinese supplier, you can request product samples and conduct thorough inspections and testing. Check for visual defects, measure critical dimensions, and perform functional testing to ensure the PCBs meet your specifications and quality standards. Additionally, you can visit the supplier’s manufacturing facility to assess their processes and quality control measures firsthand.

2. What are the common defects to look for in PCBs?

Common defects to look for in PCBs include:

– Shorts or open circuits

– Incorrect hole sizes or misaligned holes

– Inadequate or excessive solder mask coverage

– Incomplete or poor-quality surface finish

– Scratches, dents, or warping of the board

– Incorrect component placement or orientation

– Inconsistent or poor-quality silkscreen printing

3. How can I ensure the long-term reliability of PCBs?

To ensure the long-term reliability of PCBs, consider the following factors:

– Choose high-quality materials and components

– Follow industry-standard design guidelines and best practices

– Implement robust manufacturing processes with strict quality control

– Conduct accelerated life testing and environmental stress testing

– Use conformal coatings or encapsulation for protection against harsh environments

– Implement proper handling, storage, and packaging procedures

4. What should I do if I receive low-quality PCBs from a Chinese supplier?

If you receive low-quality PCBs from a Chinese supplier, take the following steps:

1. Document the defects or quality issues with photographs and detailed descriptions

2. Communicate the issues to the supplier and request an explanation and corrective action

3. Negotiate a resolution, such as a replacement, rework, or refund, depending on the severity of the issues

4. If the supplier is unresponsive or unwilling to resolve the issues, consider escalating the matter or switching to a different supplier

5. How can I maintain a good relationship with a Chinese PCB supplier?

To maintain a good relationship with a Chinese PCB supplier, follow these guidelines:

– Communicate clearly and regularly, establishing open lines of communication

– Provide accurate and detailed specifications and requirements

– Be transparent about your expectations and timeline

– Respect cultural differences and business practices

– Foster a collaborative and mutually beneficial partnership

– Promptly address any issues or concerns and work together towards resolution

– Provide feedback and recognition for good performance and quality

Conclusion

Distinguishing between good and bad PCBs from China requires a thorough understanding of the factors that contribute to PCB quality and the ability to identify reliable Chinese PCB suppliers. By considering material selection, manufacturing processes, surface finish, solder mask, and silkscreen quality, you can make informed decisions when sourcing PCBs from China.

To ensure the best possible outcomes, look for suppliers that hold relevant certifications, comply with industry standards, have advanced manufacturing capabilities, and implement robust quality control measures. Effective communication, responsive customer support, and a commitment to long-term partnerships are also key attributes of reliable Chinese PCB suppliers.

By following the guidelines outlined in this article and conducting due diligence, you can successfully navigate the Chinese PCB market and secure high-quality PCBs for your electronic projects.

Leave a Reply