Introduction to PCB Copper Thickness

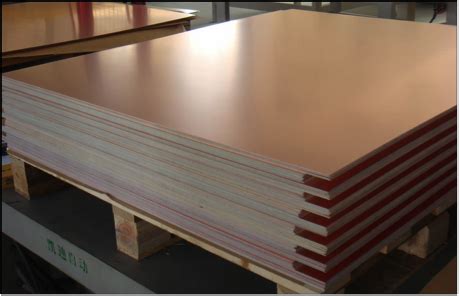

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a reliable and efficient means of interconnecting electronic components. One crucial aspect of PCB design and manufacturing is the copper thickness, which plays a significant role in determining the PCB’s electrical and thermal properties, as well as its overall durability and reliability.

In this article, we will explore the most common PCB copper thickness used in manufacturing, factors influencing the choice of copper thickness, and the advantages and disadvantages of different copper weights. By understanding these aspects, designers and manufacturers can make informed decisions when selecting the appropriate copper thickness for their PCB projects.

Understanding PCB Copper Thickness Measurement

PCB copper thickness is typically measured in ounces per square foot (oz/ft²) or microns (μm). The most common unit used in the industry is ounces per square foot, which represents the weight of copper deposited on a one-square-foot area of the PCB substrate. One ounce of copper per square foot is approximately equal to a thickness of 35 microns or 1.4 mils (thousandths of an inch).

Here is a table showing the conversion between ounces per square foot and microns:

| Ounces per Square Foot (oz/ft²) | Microns (μm) | Mils |

|---|---|---|

| 0.5 | 17.5 | 0.7 |

| 1 | 35 | 1.4 |

| 2 | 70 | 2.8 |

| 3 | 105 | 4.2 |

| 4 | 140 | 5.6 |

Common PCB Copper Thicknesses

The most common PCB copper thicknesses used in manufacturing are:

1. 1 oz/ft² (35 μm)

1 oz/ft² copper thickness is the most widely used in PCB manufacturing. It offers a good balance between electrical and thermal conductivity, cost-effectiveness, and ease of manufacturing. This thickness is suitable for a wide range of applications, including:

- Consumer electronics

- Low-power digital circuits

- Simple analog circuits

2. 2 oz/ft² (70 μm)

2 oz/ft² copper thickness is often used in applications that require higher current carrying capacity or better thermal management compared to 1 oz/ft² boards. Some common applications include:

- Power electronics

- Automotive electronics

- High-speed digital circuits

3. 0.5 oz/ft² (17.5 μm)

0.5 oz/ft² copper thickness is used in applications where weight and flexibility are critical factors, such as:

- Flexible PCBs

- Wearable electronics

- High-density interconnect (HDI) PCBs

4. 3 oz/ft² (105 μm) and 4 oz/ft² (140 μm)

3 oz/ft² and 4 oz/ft² copper thicknesses are used in high-power applications that require excellent current carrying capacity and thermal management, such as:

- Power supplies

- Motor controllers

- High-current industrial electronics

Factors Influencing the Choice of PCB Copper Thickness

Several factors influence the choice of PCB copper thickness, including:

1. Current Carrying Capacity

The current carrying capacity of a PCB trace is directly proportional to its cross-sectional area, which is determined by the trace width and copper thickness. Thicker copper allows for higher current carrying capacity, making it suitable for power electronics and high-current applications.

2. Thermal Management

Copper thickness also affects the thermal management of a PCB. Thicker copper provides better thermal conductivity, allowing for more efficient heat dissipation from components. This is particularly important in high-power applications or designs with high component density.

3. Impedance Control

In high-speed digital circuits, controlling the impedance of traces is crucial for maintaining signal integrity. Copper thickness, along with trace width and substrate properties, influences the characteristic impedance of a trace. Designers must carefully select the appropriate copper thickness to achieve the desired impedance.

4. Manufacturing Constraints

The choice of copper thickness can also be influenced by manufacturing constraints, such as:

- Minimum trace width and spacing

- Via hole size and aspect ratio

- Etching process capabilities

Thinner copper may be preferred in designs with fine pitch components or high-density layouts to ensure manufacturability.

5. Cost Considerations

Copper thickness directly impacts the cost of a PCB. Thicker copper requires more raw material and longer processing times, increasing the overall cost of the board. Designers must balance the performance requirements with cost constraints when selecting the appropriate copper thickness.

Advantages and Disadvantages of Different Copper Thicknesses

Each copper thickness has its own advantages and disadvantages, which should be considered when selecting the appropriate thickness for a given application.

1 oz/ft² (35 μm)

Advantages:

– Cost-effective

– Suitable for a wide range of applications

– Easy to manufacture

Disadvantages:

– Limited current carrying capacity

– May not provide sufficient thermal management for high-power applications

2 oz/ft² (70 μm)

Advantages:

– Higher current carrying capacity compared to 1 oz/ft²

– Better thermal management

– Suitable for power electronics and high-speed digital circuits

Disadvantages:

– More expensive than 1 oz/ft² boards

– May require wider trace widths and spacing

0.5 oz/ft² (17.5 μm)

Advantages:

– Lightweight and flexible

– Suitable for wearable electronics and flexible PCBs

– Enables high-density interconnect (HDI) designs

Disadvantages:

– Limited current carrying capacity

– Poor thermal management

– More susceptible to mechanical stress and damage

3 oz/ft² (105 μm) and 4 oz/ft² (140 μm)

Advantages:

– Excellent current carrying capacity

– Superior thermal management

– Suitable for high-power applications

Disadvantages:

– Expensive due to increased material usage and processing time

– May require wider trace widths and spacing

– Limited flexibility and increased weight

Frequently Asked Questions (FAQ)

1. What is the most common PCB copper thickness used in manufacturing?

The most common PCB copper thickness used in manufacturing is 1 oz/ft² (35 μm). This thickness offers a good balance between electrical and thermal performance, cost-effectiveness, and ease of manufacturing for a wide range of applications.

2. How does PCB copper thickness affect current carrying capacity?

PCB copper thickness directly affects the current carrying capacity of a trace. Thicker copper provides a larger cross-sectional area, allowing for higher current carrying capacity. Doubling the copper thickness, for example from 1 oz/ft² to 2 oz/ft², doubles the current carrying capacity of a trace with the same width.

3. What are the advantages of using thicker copper in PCBs?

Thicker copper in PCBs offers several advantages, including:

– Higher current carrying capacity

– Better thermal management and heat dissipation

– Improved mechanical stability and durability

These advantages make thicker copper suitable for high-power applications, automotive electronics, and designs with high component density.

4. When should I consider using 0.5 oz/ft² copper thickness in my PCB design?

You should consider using 0.5 oz/ft² copper thickness in your PCB design when:

– Weight and flexibility are critical factors, such as in wearable electronics or flexible PCBs

– You require high-density interconnect (HDI) features, as thinner copper allows for finer trace widths and spacing

– Your application has low power requirements and does not demand high current carrying capacity

5. How does PCB copper thickness affect the cost of manufacturing?

PCB copper thickness directly impacts the cost of manufacturing. Thicker copper requires more raw material and longer processing times, increasing the overall cost of the board. For example, a 2 oz/ft² board will be more expensive to manufacture than a 1 oz/ft² board due to the additional copper usage and processing requirements.

Conclusion

PCB copper thickness is a critical aspect of PCB design and manufacturing, influencing the electrical, thermal, and mechanical properties of the board. The most common PCB copper thicknesses used in manufacturing are 1 oz/ft² (35 μm), 2 oz/ft² (70 μm), 0.5 oz/ft² (17.5 μm), 3 oz/ft² (105 μm), and 4 oz/ft² (140 μm).

Designers must consider factors such as current carrying capacity, thermal management, impedance control, manufacturing constraints, and cost when selecting the appropriate copper thickness for their PCB projects. By understanding the advantages and disadvantages of different copper thicknesses and their suitability for various applications, designers and manufacturers can make informed decisions to ensure the optimal performance, reliability, and cost-effectiveness of their PCBs.

Leave a Reply