Introduction to PCB Prototyping

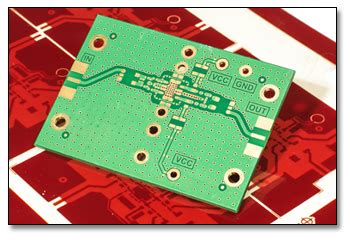

PCB (Printed Circuit Board) prototyping is an essential step in the development of electronic devices. It allows designers and engineers to test their designs before mass production, ensuring that the final product meets all the required specifications and functions as intended. With the advent of online PCB prototyping services, getting quotes and ordering prototypes has become more accessible and efficient than ever before.

What is PCB Prototyping?

PCB prototyping is the process of creating a small number of printed circuit boards for testing and validation purposes. These prototypes are used to verify the design, functionality, and performance of the electronic circuit before proceeding with mass production. Prototyping helps identify any issues or errors in the design, allowing for necessary modifications and improvements to be made early in the development process.

Benefits of PCB Prototyping

- Cost-effective: Prototyping allows for the identification and correction of design flaws before investing in large-scale production, ultimately saving money in the long run.

- Time-saving: By catching and addressing issues early, prototyping helps reduce the overall development time of the product.

- Improved quality: Prototyping enables thorough testing and refinement of the design, resulting in a higher-quality final product.

- Risk reduction: Identifying and resolving potential problems during the prototyping phase minimizes the risk of encountering issues during mass production.

Online PCB Prototyping Services

With the growth of online PCB prototyping services, obtaining quotes and ordering prototypes has become more convenient and streamlined. These services offer a full self-service experience, allowing users to upload their design files, select various manufacturing options, and receive instant quotes for their PCB prototypes.

Advantages of Online PCB Prototyping Services

- Accessibility: Online services are available 24/7, allowing users to get quotes and place orders at their convenience.

- Instant quotes: Most online PCB prototyping services provide instant quotes based on the user’s design specifications, eliminating the need for back-and-forth communication.

- Customization options: Online services offer a wide range of customization options, such as PCB thickness, copper weight, solder mask color, and surface finish, enabling users to tailor their prototypes to their specific requirements.

- Fast turnaround times: Many online PCB prototyping services offer quick turnaround times, with some providers delivering prototypes within a few days.

- Competitive pricing: The self-service nature of online PCB prototyping allows for lower prices compared to traditional prototyping methods.

Choosing the Right Online PCB Prototyping Service

When selecting an online PCB prototyping service, consider the following factors:

- Reputation and reviews: Research the service provider’s reputation and read reviews from previous customers to gauge their reliability and quality of service.

- Capabilities: Ensure that the service provider offers the necessary manufacturing capabilities and options to meet your specific requirements.

- Turnaround time: Consider the service provider’s turnaround times and whether they align with your project timeline.

- Pricing: Compare prices across different service providers to ensure you are getting a competitive rate for your PCB prototypes.

- Customer support: Look for a service provider that offers reliable customer support to assist you throughout the prototyping process.

The Online PCB Prototyping Process

The online PCB prototyping process typically involves the following steps:

- Design creation: Create your PCB design using EDA (Electronic Design Automation) software, such as Altium Designer, Eagle, or KiCad.

- Design file upload: Upload your design files (usually Gerber or ODB++ files) to the online PCB prototyping service’s website.

- Specification selection: Choose the desired specifications for your PCB prototype, such as layer count, board thickness, copper weight, solder mask color, and surface finish.

- Instant quoting: The online service will generate an instant quote based on your design files and selected specifications.

- Order placement: If satisfied with the quote, proceed to place your order and make the necessary payment.

- Fabrication: The PCB prototyping service will fabricate your prototypes according to your specifications.

- Quality control: The service provider will conduct quality control checks to ensure that your prototypes meet the required standards.

- Shipping: Once the prototypes have passed quality control, they will be shipped to your specified address.

PCB Prototyping Specifications

When ordering PCB prototypes, you will need to specify various parameters to ensure that the manufactured boards meet your requirements. Some of the key specifications include:

Layer Count

The layer count refers to the number of conductive layers in the PCB. Common layer counts include:

| Layer Count | Description |

|---|---|

| 1 | Single-sided PCB with components on one side |

| 2 | Double-sided PCB with components on both sides |

| 4 | Four-layer PCB with two internal layers for power and ground |

| 6+ | Multilayer PCBs for complex designs and high-speed circuits |

Board Thickness

PCB thickness is measured in millimeters (mm) and typically ranges from 0.4 mm to 3.2 mm. The most common PCB thicknesses are:

| Thickness (mm) | Application |

|---|---|

| 0.4 | Ultra-thin PCBs for compact devices |

| 0.8 | Thin PCBs for mobile devices and wearables |

| 1.6 | Standard thickness for most PCB applications |

| 2.0+ | Thick PCBs for high-power and mechanical strength |

Copper Weight

Copper weight refers to the thickness of the copper traces on the PCB, measured in ounces per square foot (oz/ft²). Common copper weights include:

| Copper Weight (oz/ft²) | Description |

|---|---|

| 0.5 | Thin copper for low-power and high-density designs |

| 1 | Standard copper weight for most applications |

| 2 | Thick copper for high-current and power applications |

| 3+ | Extra-thick copper for extreme current handling |

Solder Mask Color

Solder mask is a protective layer applied to the PCB to prevent solder bridging and provide insulation. Common solder mask colors include:

- Green (most common)

- Red

- Blue

- Yellow

- Black

- White

Surface Finish

The surface finish is applied to the exposed copper pads to protect them from oxidation and enhance solderability. Common surface finishes include:

- HASL (Hot Air Solder Leveling)

- ENIG (Electroless Nickel Immersion Gold)

- OSP (Organic Solderability Preservative)

- Immersion Silver

- Immersion Tin

PCB Prototyping Design Considerations

To ensure a smooth and successful PCB prototyping process, keep the following design considerations in mind:

- Design for manufacturability (DFM): Follow DFM guidelines to ensure that your design can be easily manufactured, such as maintaining proper trace widths, clearances, and hole sizes.

- Component selection: Choose components that are readily available and have standard packages to avoid delays in the prototyping process.

- Schematic and layout review: Thoroughly review your schematic and PCB layout for any errors or inconsistencies before submitting them for prototyping.

- Gerber file generation: Ensure that your EDA software generates accurate and complete Gerber files, as these are the files used by the PCB prototyping service to manufacture your boards.

- Prototype testing: Upon receiving your PCB prototypes, conduct thorough testing to validate the design and identify any issues that need to be addressed before proceeding with mass production.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity for PCB prototypes?

Most online PCB prototyping services offer low minimum order quantities, often starting from just 5 or 10 pieces. This allows designers and engineers to order small batches of prototypes for testing and validation purposes without incurring high costs.

2. How long does it take to receive PCB prototypes?

The turnaround time for PCB prototypes varies depending on the service provider and the complexity of the design. Some online services offer quick-turn prototyping, delivering prototypes within 24 to 72 hours. However, for most standard prototyping services, the turnaround time is typically between 5 to 15 business days.

3. What file formats are accepted for PCB prototyping?

The most commonly accepted file formats for PCB prototyping are Gerber (RS-274X) and ODB++ (Open Database ++). Gerber files are the industry standard for PCB fabrication, while ODB++ is a more comprehensive format that includes additional information such as component placement and netlists. Some online services also accept other formats like Eagle, Altium, and KiCad design files.

4. Can I request a specific solder mask color or surface finish?

Yes, most online PCB prototyping services offer a range of solder mask colors and surface finishes to choose from. When placing your order, you can select the desired options based on your aesthetic preferences and functional requirements.

5. What if I need to make changes to my design after placing an order?

If you need to make changes to your design after placing an order, contact the PCB prototyping service’s customer support as soon as possible. Depending on the stage of the manufacturing process, they may be able to accommodate your changes. However, keep in mind that changes made after the fabrication process has begun may incur additional costs and lead to delays in the delivery of your prototypes.

Conclusion

Online PCB prototyping services with full self-service capabilities have revolutionized the way designers and engineers obtain quotes and order prototypes for their electronic projects. By offering instant quotes, a wide range of customization options, and fast turnaround times, these services have made the prototyping process more accessible, efficient, and cost-effective.

When choosing an online PCB prototyping service, consider factors such as reputation, capabilities, turnaround time, pricing, and customer support to ensure a positive experience. By following design best practices and carefully specifying your PCB requirements, you can obtain high-quality prototypes that accurately represent your final product.

As technology continues to advance, online PCB prototyping services are expected to evolve further, offering even more features and capabilities to support the growing demands of the electronics industry. By leveraging these services, designers and engineers can streamline their development process, reduce costs, and bring their innovative products to market faster than ever before.

Leave a Reply