Key Factors Impacting Solder Joint Quality

1. Solder Alloy Composition

The composition of the solder alloy significantly impacts the quality and reliability of solder joints. Lead-free solder alloys, such as Tin-Silver-Copper (SAC) alloys, have become the standard in the electronics industry due to environmental regulations. The specific composition of the alloy affects its melting temperature, wetting behavior, and mechanical properties.

| Solder Alloy | Composition | Melting Temperature (°C) |

|---|---|---|

| Sn63Pb37 | 63% Tin, 37% Lead | 183 |

| SAC305 | 96.5% Tin, 3% Silver, 0.5% Copper | 217-220 |

| SAC405 | 95.5% Tin, 4% Silver, 0.5% Copper | 217-222 |

Choosing the appropriate solder alloy based on the application requirements and process constraints is crucial for achieving high-quality solder joints.

2. Printed Circuit Board (PCB) Design and Surface Finish

The PCB design and surface finish play a vital role in the formation of quality solder joints. Key aspects of PCB design that influence solder joint quality include:

- Pad size and shape

- Solder mask design

- Via placement and design

- Copper thickness and trace width

The surface finish of the PCB pads also affects the solderability and reliability of the joints. Common surface finishes include:

- Hot Air Solder Leveling (HASL)

- Organic Solderability Preservative (OSP)

- Electroless Nickel Immersion Gold (ENIG)

- Immersion Silver (ImAg)

- Immersion Tin (ImSn)

Each surface finish has its advantages and limitations in terms of shelf life, solderability, and compatibility with different solder alloys.

3. Component Selection and Packaging

The selection of components and their packaging types influence the quality of solder joints. Factors to consider when choosing components include:

- Package type (e.g., Through-Hole, Surface Mount, Ball Grid Array)

- Lead material and finish (e.g., Sn-Pb, pure tin, gold)

- Termination compatibility with the solder alloy

- Moisture sensitivity level (MSL) for surface mount components

Proper handling and storage of components, especially moisture-sensitive devices, are essential to prevent defects such as component cracking and delamination during the soldering process.

4. Solder Paste Properties and Printing Process

Solder paste, a mixture of solder alloy particles and flux, is a critical material in the surface mount assembly process. The properties of solder paste and the printing process significantly impact solder joint quality. Key factors include:

- Solder paste composition (alloy type, particle size, and flux)

- Rheological properties (viscosity, thixotropy, and tack)

- Stencil design (aperture size, shape, and thickness)

- Printing parameters (squeegee pressure, speed, and separation speed)

- Solder paste inspection (SPI) and quality control

Proper selection and control of solder paste properties, along with optimized stencil design and printing parameters, ensure consistent solder paste deposition and minimize defects such as bridging, insufficients, and voids.

5. Reflow Soldering Process

The reflow soldering process is a critical stage in the formation of solder joints. The quality of solder joints is influenced by several factors during reflow, including:

- Reflow temperature profile (preheat, soak, reflow, and cooling rates)

- Peak temperature and time above liquidus (TAL)

- Atmosphere control (nitrogen or air)

- Oven cleanliness and maintenance

Optimizing the reflow temperature profile based on the solder paste and component requirements is essential for achieving proper solder wetting, intermetallic compound (IMC) formation, and minimizing defects such as tombstoning, drawbridging, and head-in-pillow.

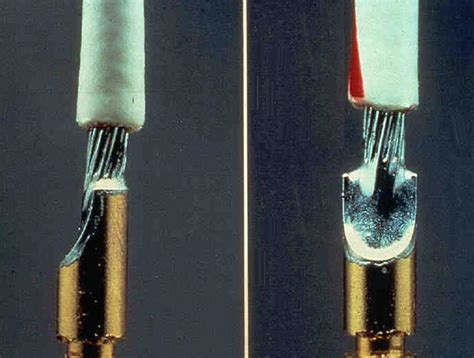

6. Cleaning and Inspection

Post-soldering cleaning and inspection play a crucial role in ensuring the quality and reliability of solder joints. Cleaning helps remove flux residues and contaminants that can lead to corrosion and electrical failures. Common cleaning methods include:

- No-clean flux (no cleaning required)

- Aqueous cleaning

- Solvent cleaning

Inspection techniques, such as visual inspection, automated optical inspection (AOI), and X-ray inspection (AXI), are used to detect solder joint defects and ensure compliance with industry standards such as IPC-A-610.

Frequently Asked Questions (FAQ)

-

Q: What is the most common lead-free solder alloy used in the electronics industry?

A: The most common lead-free solder alloy is SAC305, which contains 96.5% tin, 3% silver, and 0.5% copper. -

Q: How does the surface finish of PCB pads affect solder joint quality?

A: The surface finish of PCB pads affects the solderability, wetting behavior, and reliability of solder joints. Different surface finishes have varying shelf life, compatibility with solder alloys, and resistance to oxidation. -

Q: What are the key factors to consider when selecting solder paste for the assembly process?

A: When selecting solder paste, consider factors such as the alloy composition, particle size, flux type, rheological properties, and compatibility with the stencil design and printing process. -

Q: How can the reflow temperature profile influence solder joint quality?

A: The reflow temperature profile affects solder wetting, intermetallic compound formation, and the occurrence of defects. Optimizing the preheat, soak, reflow, and cooling rates based on the solder paste and component requirements is essential for achieving high-quality solder joints. -

Q: Why is post-soldering inspection important for ensuring solder joint quality?

A: Post-soldering inspection, using techniques such as visual inspection, AOI, and AXI, helps detect solder joint defects, ensures compliance with industry standards, and enables timely corrective actions to improve the overall quality and reliability of the electronic assembly.

Conclusion

Producing high-quality solder joints is a complex process that involves the interplay of various influential factors. From solder alloy composition and PCB design to component selection, solder paste properties, and the reflow soldering process, each factor contributes to the overall quality and reliability of solder joints.

By understanding and controlling these influential factors, electronics manufacturers can optimize their assembly processes, minimize defects, and produce reliable electronic products. Continuous monitoring, process control, and adoption of best practices are essential for achieving consistent solder joint quality in the ever-evolving electronics industry.

Leave a Reply