What is the Dielectric Constant?

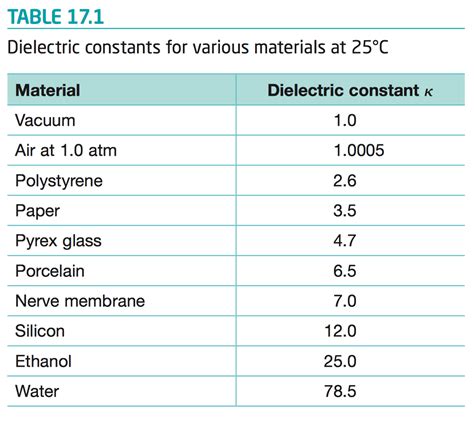

The dielectric constant, also known as the relative permittivity (εr), is a dimensionless quantity that describes a material’s ability to store electrical energy in an electric field. It is the ratio of the permittivity of a substance to the permittivity of free space (vacuum). The dielectric constant is an essential parameter in the design of electrical and electronic systems, as it affects the capacitance, impedance, and signal propagation properties of the material.

The dielectric constant of a material is determined by its molecular structure and composition. Materials with high dielectric constants have a greater ability to store electrical energy, while those with low dielectric constants have a lower capacity to store electrical energy.

Dielectric Constant Value of FR-4 Material

FR-4 is a composite material composed of a fiberglass reinforcement embedded in an epoxy resin matrix. The dielectric constant of FR-4 is a critical parameter in the design of PCBs, as it affects the signal integrity, impedance matching, and overall performance of the electronic circuits.

The dielectric constant of FR-4 material typically ranges from 4.2 to 4.6 at room temperature and a frequency of 1 MHz. However, the exact value can vary depending on several factors, such as the composition of the material, the manufacturing process, and the environmental conditions.

Factors Affecting the Dielectric Constant of FR-4

Several factors can influence the dielectric constant value of FR-4 material:

- Frequency: The dielectric constant of FR-4 is frequency-dependent. As the frequency increases, the dielectric constant tends to decrease. This is due to the material’s inability to polarize quickly enough to keep up with the changing electric field at higher frequencies.

| Frequency | Dielectric Constant |

|---|---|

| 1 MHz | 4.2 – 4.6 |

| 1 GHz | 4.1 – 4.5 |

| 10 GHz | 3.9 – 4.3 |

- Temperature: The dielectric constant of FR-4 is also temperature-dependent. As the temperature increases, the dielectric constant tends to increase. This is because the increased thermal energy allows for greater molecular motion and polarization.

| Temperature | Dielectric Constant |

|---|---|

| 25°C (77°F) | 4.2 – 4.6 |

| 50°C (122°F) | 4.3 – 4.7 |

| 75°C (167°F) | 4.4 – 4.8 |

-

Moisture Content: The presence of moisture in FR-4 material can significantly impact its dielectric constant. Water has a much higher dielectric constant (approximately 80) compared to FR-4. As the moisture content increases, the overall dielectric constant of the material increases.

-

Resin and Filler Content: The ratio of epoxy resin to fiberglass reinforcement in FR-4 can affect its dielectric constant. A higher resin content generally leads to a lower dielectric constant, while a higher fiberglass content results in a higher dielectric constant.

-

Manufacturing Process: The manufacturing process, including the curing temperature, pressure, and duration, can influence the dielectric constant of FR-4. Variations in the manufacturing process can lead to slight differences in the material’s properties.

Significance of Dielectric Constant in PCB Design

The dielectric constant of FR-4 plays a crucial role in the design and performance of printed circuit boards. Some of the key aspects influenced by the dielectric constant include:

Signal Integrity

The dielectric constant of FR-4 affects the speed and quality of signal propagation in PCBs. A higher dielectric constant results in slower signal propagation and increased signal distortion, while a lower dielectric constant enables faster signal transmission and reduced distortion. PCB designers must consider the dielectric constant when determining trace widths, spacing, and overall layout to ensure optimal signal integrity.

Impedance Matching

Impedance matching is essential for minimizing signal reflections and ensuring efficient power transfer in PCBs. The dielectric constant of FR-4 directly impacts the characteristic impedance of the traces. PCB designers must carefully select the appropriate trace dimensions and spacing based on the dielectric constant to achieve the desired impedance, typically 50Ω or 75Ω, depending on the application.

Capacitance and Crosstalk

The dielectric constant of FR-4 influences the capacitance between adjacent traces on a PCB. A higher dielectric constant leads to increased capacitance, which can result in signal crosstalk and noise. PCB designers must consider the dielectric constant when determining the spacing between traces and the use of ground planes to minimize crosstalk and maintain signal integrity.

High-Frequency Applications

As the operating frequencies of electronic devices continue to increase, the dielectric constant of FR-4 becomes even more critical. At higher frequencies, the dielectric constant of FR-4 tends to decrease, affecting the material’s performance. PCB designers must take this into account and may need to consider alternative materials with lower dielectric constants, such as Rogers or Teflon-based laminates, for high-frequency applications.

Applications of FR-4 Material

FR-4 is widely used in various industries due to its excellent mechanical, thermal, and electrical properties. Some of the common applications of FR-4 include:

-

Consumer Electronics: FR-4 is extensively used in the production of PCBs for consumer electronic devices, such as smartphones, laptops, televisions, and home appliances.

-

Automotive Electronics: The automotive industry relies on FR-4 for the fabrication of PCBs used in vehicle control systems, infotainment systems, and sensor modules.

-

Industrial Electronics: FR-4 is employed in the manufacturing of PCBs for industrial control systems, power electronics, and automation equipment.

-

Medical Devices: FR-4 is used in the production of PCBs for medical devices, such as patient monitors, diagnostic equipment, and imaging systems.

-

Aerospace and Defense: FR-4 finds applications in the aerospace and defense sectors, where it is used in the fabrication of PCBs for avionics, communication systems, and military equipment.

FAQ

-

What is the typical dielectric constant value for FR-4 material?

The typical dielectric constant value for FR-4 material ranges from 4.2 to 4.6 at room temperature and a frequency of 1 MHz. -

How does frequency affect the dielectric constant of FR-4?

As the frequency increases, the dielectric constant of FR-4 tends to decrease. This is due to the material’s inability to polarize quickly enough to keep up with the changing electric field at higher frequencies. -

What factors can influence the dielectric constant of FR-4?

Several factors can influence the dielectric constant of FR-4, including frequency, temperature, moisture content, resin and filler content, and the manufacturing process. -

Why is the dielectric constant important in PCB design?

The dielectric constant of FR-4 is crucial in PCB design because it affects signal integrity, impedance matching, capacitance, and crosstalk. PCB designers must consider the dielectric constant when determining trace dimensions, spacing, and overall layout to ensure optimal performance. -

Are there alternative materials to FR-4 for high-frequency applications?

Yes, for high-frequency applications, PCB designers may consider alternative materials with lower dielectric constants, such as Rogers or Teflon-based laminates, to maintain better signal integrity and performance.

In conclusion, the dielectric constant value of FR-4 material is a critical parameter in the design and performance of printed circuit boards. With a typical value ranging from 4.2 to 4.6 at room temperature and 1 MHz, the dielectric constant of FR-4 is influenced by various factors, including frequency, temperature, moisture content, and manufacturing process. PCB designers must carefully consider the dielectric constant when determining trace dimensions, spacing, and overall layout to ensure optimal signal integrity, impedance matching, and minimized crosstalk. As the electronics industry continues to evolve and push for higher operating frequencies, understanding and optimizing the dielectric constant of FR-4 and exploring alternative materials will remain crucial for the development of reliable and high-performance electronic devices.

Leave a Reply