What is a PCB?

A printed circuit board (PCB) is a flat board made of insulating material, typically fiberglass or composite epoxy, with conductive copper traces printed onto it. PCBs are used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate.

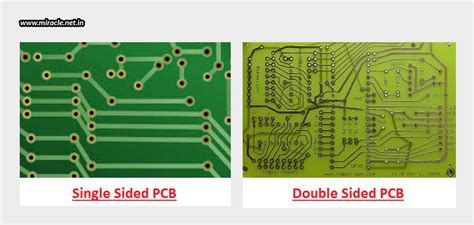

PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of the board), or multi-layer (outer and inner layers). Multi-layer PCBs allow for much higher component density, as circuits can be effectively arranged on several layers instead of a single board surface.

The main components of a PCB include:

- Substrate: The base material of the PCB, usually made of fiberglass or composite epoxy.

- Copper Layer: Thin layers of copper foil laminated onto the substrate, which are etched to create the conductive pathways.

- Solder Mask: A protective coating applied over the copper traces to prevent short circuits and corrosion.

- Silkscreen: Text and symbols printed on the PCB for identification and assembly purposes.

PCBs are designed using electronic design automation (EDA) tools, and the manufacturing process involves several steps, including:

- Design: Creating the schematic and layout of the PCB using EDA software.

- Printing: Transferring the design onto the copper-clad board using photoresist and etching processes.

- Drilling: Creating holes for through-hole components and vias (interconnects between layers).

- Plating: Applying a thin layer of metal (usually copper) to the drilled holes to create electrical connections.

- Solder Mask Application: Applying the solder mask to protect the copper traces.

- Silkscreen Printing: Adding text and symbols for identification and assembly.

- Surface Finish: Applying a protective coating to the exposed copper to prevent oxidation and improve solderability.

PCBs are used in nearly all electronic devices, from simple single-layer boards in toys and appliances to complex multi-layer boards in computers, smartphones, and aerospace equipment.

What is an Integrated Circuit?

An integrated circuit (IC), also known as a microchip or chip, is a miniaturized electronic circuit consisting of semiconductor devices, passive components, and interconnects fabricated onto a thin substrate of semiconductor material, typically silicon. ICs are designed to perform specific functions, such as amplification, signal processing, memory storage, or microprocessor operations.

The main components of an IC include:

- Semiconductor Substrate: Usually made of silicon, this serves as the foundation for the IC.

- Transistors: The basic building blocks of ICs, used for amplification and switching.

- Diodes: Used for rectification and protection against electrostatic discharge (ESD).

- Resistors: Used to control current flow and provide voltage drops.

- Capacitors: Used for energy storage, filtering, and decoupling.

- Interconnects: Metal layers that connect the various components within the IC.

ICs are manufactured using a complex process called photolithography, which involves several steps:

- Wafer Fabrication: Creating a pure silicon wafer through crystal growth and slicing.

- Photolithography: Transferring the IC design onto the wafer using light-sensitive materials and masks.

- Etching: Removing unwanted material to create the desired patterns on the wafer.

- Doping: Introducing impurities into the silicon to create N-type and P-type regions for transistors and other components.

- Insulation and Metallization: Adding insulating layers (usually silicon dioxide) and metal interconnects (usually aluminum or copper) to connect the components.

- Packaging: Encasing the IC die in a protective package with external pins for connection to a PCB.

ICs come in various types, including:

- Analog ICs: Used for processing continuous signals, such as amplifiers, voltage regulators, and sensors.

- Digital ICs: Used for processing discrete signals, such as logic gates, microprocessors, and memory devices.

- Mixed-signal ICs: Combine both analog and digital functions on a single chip.

ICs have revolutionized electronics by enabling the miniaturization and increased functionality of devices while reducing power consumption and cost. They are found in virtually all modern electronic devices, from consumer electronics to industrial equipment and aerospace systems.

Key Differences between PCBs and ICs

While both PCBs and ICs are essential components in electronic systems, they serve different purposes and have distinct characteristics. The main differences between PCBs and ICs are:

| Characteristic | PCB | IC |

|---|---|---|

| Function | Provides mechanical support and electrical interconnection for electronic components | Performs specific electronic functions (e.g., amplification, signal processing, memory storage) |

| Structure | Flat board with conductive traces and component mounting pads | Miniaturized electronic circuit with semiconductor devices, passive components, and interconnects |

| Materials | Insulating substrate (usually fiberglass or composite epoxy) with copper traces | Semiconductor substrate (usually silicon) with various materials for components and interconnects |

| Manufacturing Process | Etching, drilling, plating, and coating processes | Photolithography, etching, doping, insulation, and metallization processes |

| Integration Level | Integrates discrete components and ICs onto a single board | Integrates multiple electronic functions onto a single semiconductor chip |

| Customization | Can be easily customized for specific applications by changing the layout and component selection | Requires significant design and manufacturing efforts to customize, often limited to large-volume applications |

| Cost | Relatively low cost, especially for low-complexity and low-volume applications | High initial design and setup costs, but low per-unit costs for high-volume production |

| Size | Larger than ICs, with sizes ranging from a few square centimeters to several square meters | Miniaturized, with sizes ranging from a few square millimeters to a few square centimeters |

| Packaging | Not applicable, as PCBs are used to mount and interconnect packaged components | ICs are packaged in various forms, such as DIP, QFP, BGA, or CSP, for mounting onto PCBs |

Role of PCBs and ICs in Electronic Systems

PCBs and ICs play complementary roles in electronic systems:

-

PCBs provide the physical platform for mounting and interconnecting electronic components, including ICs, discrete components (resistors, capacitors, inductors), connectors, and other modules.

-

ICs, mounted onto PCBs, perform specific electronic functions, such as signal processing, computation, memory storage, power management, and communication.

The combination of PCBs and ICs enables the creation of complex electronic systems with enhanced functionality, reduced size, and improved reliability. PCBs allow for the organized layout and routing of components, while ICs provide the necessary electronic functions in a compact and efficient form factor.

In a typical electronic product development process, the system design is first partitioned into functional blocks, which are then allocated to either discrete components, ICs, or a combination of both. The chosen components are then laid out on a PCB, considering factors such as signal integrity, power distribution, thermal management, and mechanical constraints. The PCB design is then fabricated, populated with components (including ICs), and tested to ensure proper functionality and performance.

As technology advances, there is a growing trend towards higher levels of integration, with more functions being incorporated into ICs to reduce the overall component count and PCB size. This is evident in the development of system-on-chip (SoC) devices, which integrate multiple functions (e.g., processors, memory, I/O interfaces) onto a single IC. However, PCBs remain essential for providing the necessary interconnections, power distribution, and mechanical support for these highly integrated components.

Future Trends in PCBs and ICs

The electronics industry is constantly evolving, driven by the demand for smaller, faster, and more efficient devices. Some of the key trends shaping the future of PCBs and ICs include:

-

Advanced PCB Materials: The development of new PCB substrate materials, such as high-frequency laminates and flexible substrates, to support higher signal speeds, improved thermal management, and increased mechanical flexibility.

-

High-Density Interconnect (HDI) PCBs: The use of finer trace widths, smaller via sizes, and multiple layers to accommodate the increasing density of components and interconnects in miniaturized devices.

-

3D IC Packaging: The stacking of multiple IC dies vertically using through-silicon vias (TSVs) to create 3D ICs, enabling higher levels of integration and reduced package sizes.

-

Advanced Semiconductor Technologies: The continuous scaling of semiconductor fabrication processes (e.g., 7nm, 5nm, 3nm) to create smaller, faster, and more power-efficient transistors, enabling the development of more complex and capable ICs.

-

System-in-Package (SiP) Solutions: The integration of multiple ICs and passive components into a single package, often using advanced packaging techniques like fan-out wafer-level packaging (FOWLP) or embedded die packaging, to create compact and high-performance modules.

-

Additive Manufacturing for Electronics: The use of 3D printing technologies, such as inkjet printing and aerosol jet printing, to fabricate PCBs and even ICs, enabling rapid prototyping, customization, and the creation of complex 3D structures.

-

IoT and Edge Computing: The proliferation of connected devices and the need for local data processing in Internet of Things (IoT) applications driving the development of low-power, high-performance ICs and specialized PCBs for edge computing nodes.

As these trends continue to shape the electronics landscape, close collaboration between PCB designers, IC designers, and system architects will be crucial to create innovative and optimized solutions that meet the ever-increasing demands of modern electronic devices.

Frequently Asked Questions (FAQ)

-

Can a PCB function without ICs?

Yes, a PCB can function without ICs if it only contains discrete components like resistors, capacitors, and inductors. However, most modern electronic devices require the use of ICs to achieve the necessary functionality and performance. -

Are all ICs mounted on PCBs?

No, not all ICs are mounted on PCBs. Some ICs, such as those used in high-performance computing or specialized applications, may be directly mounted on other substrates like ceramic or metal carriers. However, the vast majority of ICs are designed to be mounted on PCBs for use in electronic devices. -

Can PCBs be repaired if damaged?

In some cases, PCBs can be repaired if the damage is localized and does not affect multiple layers or components. Common repair techniques include soldering, jumper wire installation, and trace repair. However, extensive damage may require the replacement of the entire PCB. -

What is the difference between a microprocessor and an IC?

A microprocessor is a type of IC that contains a central processing unit (CPU) and other supporting components, designed to execute programmed instructions and perform general-purpose computing tasks. While all microprocessors are ICs, not all ICs are microprocessors, as ICs can be designed for various other functions like memory storage, signal processing, or power management. -

How do I choose between using discrete components or an IC for a given function?

The choice between discrete components and an IC depends on factors such as the complexity of the function, performance requirements, available board space, and cost. ICs are generally preferred for complex, high-performance, or space-constrained applications, while discrete components may be suitable for simpler, low-volume, or cost-sensitive designs. In many cases, a combination of both discrete components and ICs is used to strike a balance between functionality, performance, and cost.

Leave a Reply