Introduction to Flex PCBs

Flexible printed circuit boards (Flex PCBs) have gained significant popularity in recent years due to their versatility and ability to conform to various shapes and sizes. Unlike traditional rigid PCBs, flex PCBs are designed to bend and twist, making them ideal for applications that require flexibility, such as wearable devices, medical equipment, and aerospace systems. This article will delve into the materials and layer stackup of flex PCBs, providing a comprehensive understanding of their construction and properties.

What is a Flex PCB?

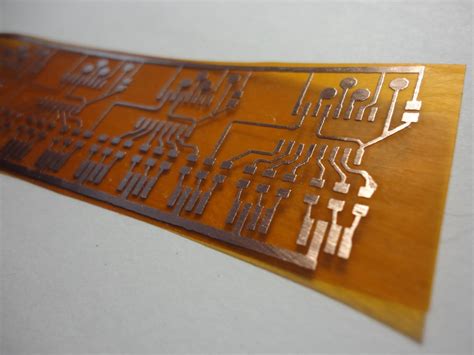

A flex PCB is a type of printed circuit board that consists of a thin, flexible substrate with conductive traces and components mounted on its surface. The flexibility of the board is achieved through the use of special materials, such as polyimide or polyester, which can withstand repeated bending and flexing without breaking or losing their electrical properties.

Flex PCBs offer several advantages over rigid PCBs, including:

- Reduced weight and space requirements

- Increased reliability due to fewer interconnects

- Improved signal integrity and reduced EMI

- Enhanced design flexibility and conformability

Flex PCB Materials

The choice of materials for flex PCBs is critical to their performance and reliability. The most common materials used in flex PCB construction are:

Polyimide (PI)

Polyimide is the most widely used substrate material for flex PCBs due to its excellent thermal stability, chemical resistance, and mechanical properties. It can withstand temperatures up to 300°C and has a high dielectric strength, making it suitable for high-reliability applications. Polyimide is available in various thicknesses, typically ranging from 12.5 μm to 125 μm.

Polyester (PET)

Polyester is another popular substrate material for flex PCBs, particularly in consumer electronics and low-cost applications. It has good electrical properties and is less expensive than polyimide. However, it has a lower temperature resistance (up to 150°C) and is more susceptible to moisture absorption.

Adhesives

Adhesives are used to bond the conductive layers to the substrate material. The most common adhesives used in flex PCBs are acrylic and epoxy-based. Acrylic adhesives offer good flexibility and are suitable for dynamic flexing applications, while epoxy adhesives provide better thermal stability and chemical resistance.

Copper

Copper is the most widely used conductor material in flex PCBs due to its excellent electrical conductivity and mechanical properties. The thickness of the copper layer can vary depending on the application, with typical values ranging from 9 μm to 70 μm.

Flex PCB Layer Stackup

The layer stackup of a flex PCB refers to the arrangement of conductive and insulating layers that make up the board. The number and type of layers depend on the complexity of the design and the application requirements. Some common flex PCB layer stackups include:

Single-Layer Flex PCB

A single-layer flex PCB consists of a single conductive layer (usually copper) bonded to a flexible substrate. This type of stackup is suitable for simple, low-density designs with few interconnects.

Double-Layer Flex PCB

A double-layer flex PCB has two conductive layers separated by a flexible substrate. The layers are interconnected through plated through-holes (PTHs) or microvias. Double-layer flex PCBs offer higher routing density and better signal integrity compared to single-layer designs.

Multi-Layer Flex PCB

Multi-layer flex PCBs consist of three or more conductive layers separated by flexible substrates. The layers are interconnected through PTHs, microvias, or a combination of both. Multi-layer flex PCBs are used in complex, high-density designs that require multiple power and ground planes, as well as high-speed signal routing.

Here’s an example of a typical four-layer flex PCB stackup:

| Layer | Material | Thickness (μm) |

|---|---|---|

| Top Cover | Polyimide | 25 |

| Top Copper | Copper | 18 |

| Adhesive | Acrylic | 25 |

| Core | Polyimide | 50 |

| Adhesive | Acrylic | 25 |

| Bottom Copper | Copper | 18 |

| Bottom Cover | Polyimide | 25 |

Flex PCB Design Considerations

When designing a flex PCB, several factors must be considered to ensure optimal performance and reliability:

Bend Radius

The bend radius is the minimum radius that a flex PCB can be bent without causing damage or affecting its electrical properties. The bend radius depends on the thickness and material of the substrate, as well as the copper weight and adhesive type. As a general rule, the minimum bend radius should be at least six times the total thickness of the board.

Copper Weight

The copper weight, or thickness, of the conductive layers affects the flexibility and current-carrying capacity of the flex PCB. Thinner copper layers (e.g., 9 μm or 18 μm) are more flexible but have lower current-carrying capacity, while thicker layers (e.g., 35 μm or 70 μm) are less flexible but can handle higher currents.

Coverlay

A coverlay is a protective layer applied to the outer surfaces of the flex PCB to provide insulation and mechanical protection. The choice of coverlay material and thickness depends on the application requirements, such as flexibility, chemical resistance, and wear resistance.

Stiffeners

Stiffeners are rigid materials, such as FR-4 or polyimide, that are selectively bonded to the flex PCB to provide local reinforcement and improve the mechanical stability of connectors and components. Stiffeners can also be used to define the bending zones of the flex PCB.

Flex PCB Manufacturing Process

The manufacturing process for flex PCBs is similar to that of rigid PCBs, with some additional steps to accommodate the flexible nature of the materials:

-

Material Selection: The appropriate substrate, adhesive, and copper materials are selected based on the application requirements.

-

Lamination: The conductive layers are bonded to the substrate using heat and pressure in a lamination press.

-

Drilling: Through-holes and vias are drilled into the laminated board using mechanical or laser drilling methods.

-

Plating: The drilled holes are plated with copper to establish electrical connections between the layers.

-

Patterning: The desired circuit pattern is transferred onto the copper layers using photolithography and etching processes.

-

Coverlay Application: The coverlay is laminated onto the outer surfaces of the flex PCB to provide insulation and protection.

-

Solder Mask Application: A solder mask is applied to the exposed copper areas to prevent solder bridging and provide additional insulation (optional).

-

Surface Finish: A surface finish, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), is applied to the exposed copper pads to improve solderability and protect against oxidation.

-

Singulation: The individual flex PCBs are cut out from the production panel using mechanical or laser methods.

FAQ

1. What is the difference between a flex PCB and a rigid PCB?

A flex PCB is a printed circuit board that uses flexible substrate materials, such as polyimide or polyester, to allow the board to bend and flex. In contrast, a rigid PCB uses a rigid substrate material, such as FR-4, which does not allow for flexing.

2. Can flex PCBs be used in high-temperature applications?

Yes, flex PCBs made with polyimide substrates can withstand temperatures up to 300°C, making them suitable for high-temperature applications. However, the choice of adhesive and coverlay materials must also be considered for high-temperature operation.

3. What is the minimum bend radius for a flex PCB?

The minimum bend radius for a flex PCB depends on the thickness and material of the substrate, as well as the copper weight and adhesive type. As a general rule, the minimum bend radius should be at least six times the total thickness of the board.

4. Can flex PCBs be used in high-frequency applications?

Yes, flex PCBs can be used in high-frequency applications, such as RF and microwave devices. However, the design must take into account the dielectric properties of the substrate material and the potential for signal integrity issues due to the flexible nature of the board.

5. How do I choose the right material for my flex PCB application?

The choice of material for a flex PCB depends on several factors, including the operating temperature range, chemical exposure, mechanical requirements, and cost. Polyimide is the most common choice for high-reliability applications, while polyester is often used in consumer electronics and low-cost applications. It is recommended to consult with a flex PCB manufacturer or material supplier to determine the best material for your specific application.

Conclusion

Flex PCBs offer a unique combination of flexibility, reliability, and performance that makes them ideal for a wide range of applications. By understanding the materials and layer stackup options available, designers can create flex PCBs that meet the specific requirements of their projects. As technology continues to advance, the demand for flex PCBs is expected to grow, driven by the increasing miniaturization and complexity of electronic devices.

Leave a Reply