What is a Breadboard?

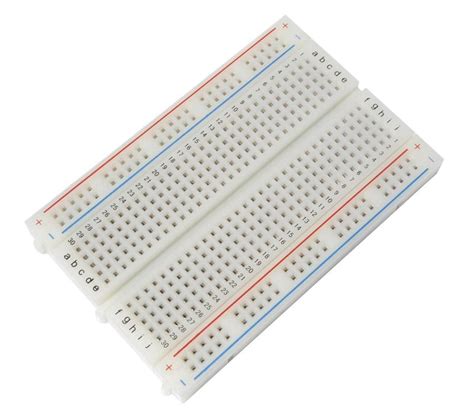

A breadboard is a rectangular plastic board with a grid of holes used for prototyping electronic circuits. It allows designers and engineers to quickly build and test circuit designs without the need for soldering. Breadboards are an essential tool for anyone working with electronics, from beginners learning the basics to experienced professionals developing complex systems.

How Does a Breadboard Work?

Breadboards have a series of interconnected metal clips underneath the plastic surface. These clips are arranged in a specific pattern to allow for easy connection of electronic components. The holes on the breadboard are spaced at a standard 0.1-inch (2.54mm) interval, which is compatible with most through-hole electronic components.

The typical breadboard layout consists of two main sections:

-

Terminal Strips: These are the long horizontal rows at the top and bottom of the breadboard, often labeled with red (+) and blue (-) lines. These strips are used for connecting power supply and ground connections to the circuit.

-

Component Strips: These are the main area of the breadboard where components are placed. The component strips are divided into two sections, with a center gap separating them. Each strip has five interconnected holes, which are electrically connected horizontally.

By placing components and wires into the appropriate holes, designers can create electrical connections and build their circuits without the need for soldering.

Advantages of Using a Breadboard

1. Quick and Easy Prototyping

One of the main advantages of using a breadboard is the ability to quickly and easily prototype electronic circuits. With a breadboard, you can simply insert components and wires into the appropriate holes to create your circuit. If you need to make changes, you can easily remove or reposition components without damaging them or the board.

2. No Soldering Required

Breadboards eliminate the need for soldering during the prototyping phase. This saves time and effort, as soldering can be a time-consuming and delicate process. It also allows for greater flexibility in circuit design, as components can be easily swapped or rearranged.

3. Reusability

Unlike PCBs, which are permanently etched with a specific circuit design, breadboards are reusable. Once you have finished testing a particular circuit, you can simply remove the components and wires and use the breadboard for your next project. This makes breadboards a cost-effective solution for prototyping, as you don’t need to manufacture a new board for each iteration of your design.

4. Ideal for Education and Learning

Breadboards are an excellent tool for teaching and learning electronics. They provide a hands-on approach to circuit building, allowing students to experiment with different components and designs. The visual nature of breadboards also helps students understand how circuits work and how components interact with each other.

Types of Breadboards

There are several types of breadboards available, each with different sizes and features to suit various needs.

1. Solderless Breadboards

Solderless breadboards are the most common type and are suitable for most prototyping needs. They come in various sizes, from small 170-tie-point boards to large 2,390-tie-point boards. Solderless breadboards have the standard layout with terminal strips and component strips.

2. Modular Breadboards

Modular breadboards consist of multiple smaller breadboards that can be connected together to create larger prototyping areas. This allows for greater flexibility in circuit design and can accommodate more complex projects. Modular breadboards often have additional features, such as built-in power supplies and binding posts for external connections.

3. PCB-Mounted Breadboards

PCB-mounted breadboards are designed to be soldered directly onto a printed circuit board (PCB). These breadboards have solderable pins instead of the standard metal clips, allowing for a permanent connection to the PCB. PCB-mounted breadboards are useful for creating custom development boards or integrating prototyped circuits into a final PCB design.

How to Use a Breadboard

Using a breadboard is relatively simple, but it’s essential to understand the basic principles to ensure your circuit works as intended.

Step 1: Identify the Breadboard Sections

Before you start building your circuit, familiarize yourself with the different sections of the breadboard. Identify the terminal strips (power rails) and the component strips. Note the center gap that separates the component strips into two halves.

Step 2: Plan Your Circuit Layout

Sketch your circuit diagram and plan how you will lay out the components on the breadboard. Consider the placement of each component and how they will connect. Ensure you have enough space on the breadboard for all your components and wires.

Step 3: Place Components

Begin placing your components on the breadboard. Insert the component leads into the appropriate holes, ensuring that each lead is in a separate row on the component strips. Pay attention to the orientation of polarized components, such as diodes and electrolytic capacitors.

Step 4: Make Connections

Use jumper wires to make connections between components and the power rails. Insulated solid-core wires are recommended for breadboarding, as they provide a secure fit and reduce the risk of short circuits. When making connections, ensure that the wires are fully inserted into the holes and that there are no loose strands.

Step 5: Connect Power Supply

Connect your power supply to the terminal strips (power rails) on the breadboard. Typically, the red strip is used for the positive voltage, and the blue strip is used for the negative voltage (ground). Double-check your connections to ensure proper polarity and avoid damage to your components.

Step 6: Test and Debug

Once your circuit is complete, double-check all connections and component placements. Apply power to your circuit and test its functionality. If your circuit does not work as expected, carefully review your connections and refer to your circuit diagram to identify and resolve any issues.

Tips and Best Practices

To get the most out of your breadboarding experience, consider the following tips and best practices:

-

Keep your breadboard clean: Regularly clean your breadboard to remove dust and debris that can cause short circuits or poor connections.

-

Use color-coded wires: Use different colored wires for power, ground, and signal connections to make your circuit more organized and easier to debug.

-

Avoid overloading the breadboard: Be mindful of the current limitations of your breadboard and avoid overloading it with too many high-current components.

-

Use shorter wires: Whenever possible, use shorter wires to make connections. Longer wires can introduce unwanted resistance and capacitance, which can affect circuit performance.

-

Label your components: Use labels or masking tape to identify your components on the breadboard. This makes it easier to troubleshoot and modify your circuit as needed.

-

Prototype in stages: For complex circuits, prototype your design in stages. Test each section of your circuit independently before integrating them together.

-

Document your work: Keep a record of your circuit diagrams, component values, and any modifications made during the prototyping process. This documentation will be valuable when transitioning your design to a PCB.

Frequently Asked Questions (FAQ)

1. Can I reuse a breadboard after soldering components on it?

No, once you have soldered components onto a breadboard, it is no longer reusable for prototyping. Soldering will permanently bond the components to the breadboard, making it difficult to remove them without damaging the board. If you need to create a permanent circuit, consider using a PCB-mounted breadboard or transferring your design to a custom PCB.

2. How do I clean my breadboard?

To clean your breadboard, start by removing all components and wires. Use compressed air to blow out any dust or debris from the holes and surface of the board. For stubborn dirt or residue, you can gently scrub the board with a soft-bristled brush and isopropyl alcohol. Be sure to let the breadboard dry completely before using it again.

3. Can I use a breadboard for high-frequency circuits?

Breadboards are not ideal for high-frequency circuits due to their inherent capacitance and resistance. The long metal clips and jumper wires can introduce unwanted parasitic effects that can distort high-frequency signals. For high-frequency applications, it is recommended to use a dedicated PCB or specialized prototyping boards designed for high-frequency use.

4. Can breadboards handle high-current applications?

Breadboards have limited current-carrying capacity due to the size and material of the metal clips. Most breadboards are rated for a maximum current of around 1A per contact point. If your circuit requires higher currents, it is advisable to use terminal blocks or dedicated high-current connectors instead of relying solely on the breadboard.

5. How long can I expect my breadboard to last?

The lifespan of a breadboard depends on several factors, such as the quality of the board, the frequency of use, and the environment in which it is used. With proper care and handling, a high-quality breadboard can last for many years. However, over time, the metal clips may lose their elasticity, resulting in looser connections and potential contact issues. If you notice any signs of wear or inconsistent performance, it may be time to replace your breadboard.

Conclusion

Breadboards are an indispensable tool for anyone working with electronics, offering a quick, easy, and solderless way to prototype circuits. By understanding the different types of breadboards, their advantages, and how to use them effectively, you can streamline your design process and bring your electronic projects to life more efficiently.

Remember to follow best practices, such as keeping your breadboard clean, using color-coded wires, and documenting your work to ensure a smooth prototyping experience. With a breadboard in hand and a solid understanding of its capabilities, you’ll be well-equipped to tackle a wide range of electronic projects, from simple circuits to complex systems.

Word count: 1709

Leave a Reply