PCB Blog

-

What is Peelable Soldermask?

Posted by

–

Read more: What is Peelable Soldermask?

Read more: What is Peelable Soldermask?How Peelable Soldermask Works Peelable soldermask is applied to a PCB in the same way as traditional permanent soldermask, typically through screen printing or spray coating. However, the composition of peelable soldermask is different, allowing it to be removed cleanly from the PCB surface when required. Composition of Peelable Soldermask […]

-

How is LPI Solder Mask Applied?

Posted by

–

Read more: How is LPI Solder Mask Applied?

Read more: How is LPI Solder Mask Applied?What is LPI Solder Mask? LPI solder mask is a photosensitive polymer coating that is applied to the surface of a PCB. It is designed to selectively expose and cure when subjected to ultraviolet (UV) light, creating a permanent protective layer on the PCB. The LPI solder mask is typically […]

-

What is a Peelable Soldermask?

Posted by

–

Read more: What is a Peelable Soldermask?

Read more: What is a Peelable Soldermask?How Peelable Soldermasks Work Peelable soldermasks are typically made from a polymer-based material that is applied to the PCB surface using screen printing, spray coating, or dip coating methods. The mask is then cured using heat or ultraviolet (UV) light, depending on the specific material used. Once the soldering process […]

-

What Is The Typical Powder Spray Process?

Posted by

–

Read more: What Is The Typical Powder Spray Process?

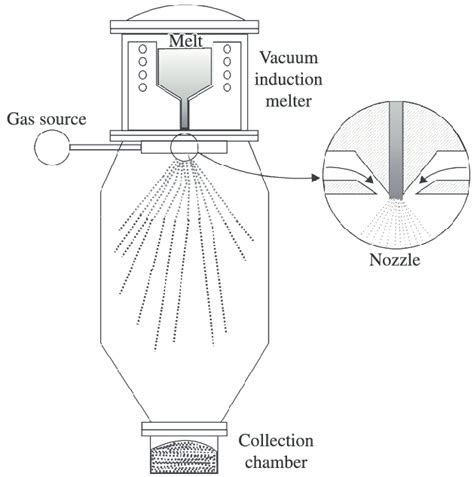

Read more: What Is The Typical Powder Spray Process?How Does Powder Spray Coating Work? The powder spray coating process works by using electrostatic attraction to adhere powdered polymers to a substrate, which are then melted and cured in an oven to form a protective or decorative coating. The main steps in the process are: Powder preparation: The powdered […]

-

Read more: What are the differences between solder mask and paste mask?

Read more: What are the differences between solder mask and paste mask?What is solder mask? Solder mask, also known as solder resist or solder stop, is a thin, protective layer applied to the copper traces and pads on a PCB. Its primary purpose is to prevent solder from adhering to areas where it is not intended to be, thus preventing short […]

-

Read more: Advantages and Disadvantages of Electrostatic Powder Spray

Read more: Advantages and Disadvantages of Electrostatic Powder SprayIntroduction to Electrostatic Powder Spray Electrostatic powder spray is a coating technique that has gained significant popularity in various industries due to its numerous advantages. This method involves applying a dry powder coating material to a substrate using an electrostatic charge. The electrostatic charge causes the powder particles to adhere […]

-

Red Solder Resist is Eye-catching

Posted by

–

Read more: Red Solder Resist is Eye-catching

Read more: Red Solder Resist is Eye-catchingWhat is Solder Resist? Solder resist, or solder mask, is a protective coating applied to the copper traces of a PCB. Its primary functions are: Preventing solder bridges from forming between closely spaced solder pads Protecting the copper traces from oxidation and corrosion Providing electrical insulation Improving the aesthetics of […]

-

Reasons of Solder Mask Bridge Breaking Off

Posted by

–

Read more: Reasons of Solder Mask Bridge Breaking Off

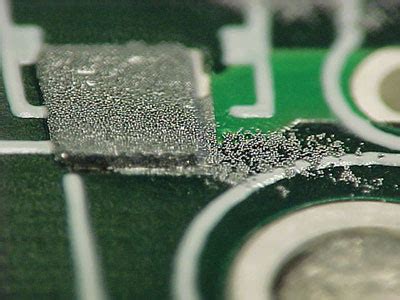

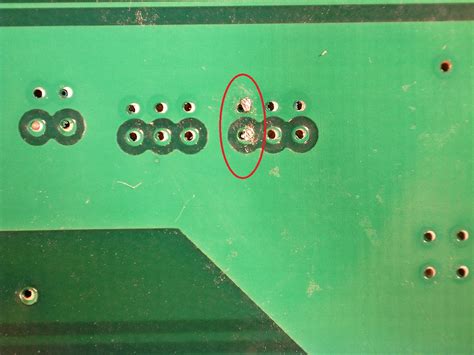

Read more: Reasons of Solder Mask Bridge Breaking OffUnderstanding Solder Mask Breakoff and Its Implications Solder mask, also known as solder resist or solder stop, is a thin layer of polymer applied to the copper traces of a printed circuit board (PCB). Its primary function is to protect the copper traces from oxidation, prevent solder bridges from forming […]

-

Colorful Life with Colorful Soldermask

Posted by

–

Read more: Colorful Life with Colorful Soldermask

Read more: Colorful Life with Colorful SoldermaskIntroduction to Colorful Soldermask In the world of printed circuit boards (PCBs), soldermask plays a crucial role in protecting the copper traces and preventing short circuits. Traditionally, green has been the most common color for soldermasks. However, with the advent of ColorfulSoldermask, PCB designers now have the opportunity to bring […]

-

What is solder mask dam?

Posted by

–

Read more: What is solder mask dam?

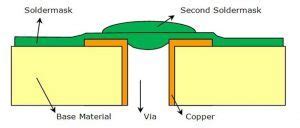

Read more: What is solder mask dam?How Solder Mask Dam Works The solder mask dam technique is implemented during the PCB manufacturing process. Here’s a step-by-step explanation of how it works: PCB Design: During the PCB design phase, the copper pads for components are defined with a specific size and shape. The solder mask layer is […]

Recent Posts

- Best Practices to Ensure the Correct Component Orientation by Optimized assembly PCB board!

- Build a New Product quickly with PCB Assembly Prototyping – A Brief Guide!

- Can you provide complete PCB box-build services?

- Tips for Choosing the Perfect Cable Assembly Manufacturer!

- Top 10 Best PCB routing practices!

Categories

- PCB Blog 835