Introduction to IC programming

Integrated Circuit (IC) programming is a crucial step in the Printed Circuit Board (PCB) assembly process. It involves configuring the programmable ICs with the desired functionality and parameters before they are soldered onto the PCB. This process ensures that the ICs operate as intended and the overall PCB functions according to the design specifications.

What are Programmable ICs?

Programmable ICs are integrated circuits that can be configured or programmed to perform specific functions. Unlike fixed-function ICs, which have predefined functionality, programmable ICs offer flexibility and customization. They allow designers to implement complex logic functions, memory storage, and other features tailored to their specific application requirements.

Some common types of programmable ICs include:

- Microcontrollers

- Field Programmable Gate Arrays (FPGAs)

- Complex Programmable Logic Devices (CPLDs)

- Electrically Erasable Programmable Read-Only Memory (EEPROM)

- Flash Memory

Importance of IC Programming in PCB Assembly

IC programming plays a vital role in PCB assembly for several reasons:

-

Customization: Programmable ICs allow designers to customize the functionality of the PCB according to their specific requirements. By programming the ICs, designers can implement unique features, optimize performance, and adapt the PCB to different applications.

-

Cost-effectiveness: Using programmable ICs can be more cost-effective compared to designing and manufacturing custom fixed-function ICs. Programmable ICs offer a flexible solution that can be configured for different projects, reducing the need for expensive custom silicon.

-

Flexibility and Upgradability: Programmable ICs provide the ability to modify or upgrade the functionality of the PCB even after it has been manufactured. By reprogramming the ICs, designers can add new features, fix bugs, or adapt the PCB to changing requirements without the need for hardware modifications.

-

Time-to-Market: IC programming allows for faster development cycles and shorter time-to-market. Instead of waiting for custom ICs to be designed and manufactured, programmable ICs can be quickly configured and integrated into the PCB assembly process, accelerating the overall product development timeline.

IC Programming Methods

There are several methods used for programming ICs in PCB assembly. The choice of programming method depends on factors such as the type of IC, the programming interface, and the production volume. Here are some common IC programming methods:

In-System Programming (ISP)

In-System Programming (ISP) is a method where the IC is programmed while it is already soldered onto the PCB. This method requires a programming interface, such as JTAG (Joint Test Action Group) or SPI (Serial Peripheral Interface), to be available on the PCB. ISP allows for programming and debugging of the IC without the need for removal from the PCB.

Advantages of ISP:

– Convenient programming without IC removal

– Supports programming and debugging of the IC in its final application environment

– Enables field updates and firmware upgrades

Disadvantages of ISP:

– Requires additional programming interface circuitry on the PCB

– May have slower programming speeds compared to other methods

– Potential for programming errors due to signal integrity issues on the PCB

Off-Board Programming

Off-board programming involves removing the IC from the PCB and programming it using a standalone programmer or a programming socket. This method is commonly used for pre-programming ICs before they are soldered onto the PCB.

Advantages of off-board programming:

– Faster programming speeds compared to ISP

– Reduces the risk of programming errors due to controlled programming environment

– Allows for bulk programming of ICs before PCB assembly

Disadvantages of off-board programming:

– Requires additional handling and removal of ICs from the PCB

– Potential for damage to ICs during removal and reinsertion

– Increases the overall assembly time and cost

In-Circuit Programming

In-circuit programming is a method where the IC is programmed while it is connected to the PCB, but without using the PCB’s programming interface. This method typically involves using a specialized programming fixture or a test point access system to establish a direct connection with the IC’s programming pins.

Advantages of in-circuit programming:

– Allows for programming of ICs that do not have an accessible programming interface on the PCB

– Provides faster programming speeds compared to ISP

– Enables programming of ICs in their final application environment

Disadvantages of in-circuit programming:

– Requires specialized programming fixtures or test point access systems

– May be more complex and time-consuming to set up compared to other methods

– Potential for damage to ICs or PCB during the programming process

IC Programming Tools and Equipment

To perform IC programming in PCB assembly, various tools and equipment are used. These tools facilitate the programming process, ensure accurate and reliable programming, and support different programming methods. Some common IC programming tools and equipment include:

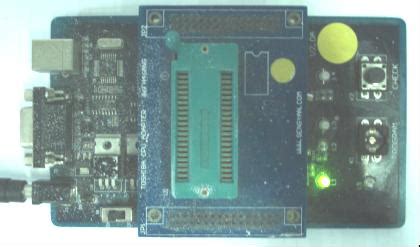

Device Programmers

Device programmers are standalone units used for programming ICs. They typically support a wide range of IC devices and programming interfaces. Device programmers are often used for off-board programming, where the ICs are programmed before being soldered onto the PCB.

Features of device programmers:

– Support for multiple IC devices and programming interfaces

– High-speed programming capabilities

– Standalone operation without the need for a host computer

– Built-in verification and error checking mechanisms

Programming Fixtures

Programming fixtures are specialized jigs or adapters used for in-circuit programming. They provide a direct connection between the programmer and the IC’s programming pins on the PCB. Programming fixtures ensure accurate and reliable programming by maintaining proper alignment and contact with the IC pins.

Features of programming fixtures:

– Customized design to match the specific PCB layout and IC package

– Precise alignment and contact with the IC pins

– Compatibility with different programming tools and interfaces

– Durable construction to withstand repeated programming cycles

Test Point Access Systems

Test point access systems are used to establish temporary connections with the IC’s programming pins on the PCB. These systems typically involve spring-loaded probes or pogo pins that make contact with test points or vias on the PCB, allowing for in-circuit programming without the need for a dedicated programming fixture.

Features of test point access systems:

– Flexibility to access programming pins on different PCB layouts

– Quick and easy setup for programming

– Compatibility with various programming tools and interfaces

– Ideal for low-volume production or prototype programming

Programming Software

Programming software is used to control the programming process, configure the ICs, and manage the programming data. It provides a user interface for selecting the target device, setting programming parameters, and monitoring the programming progress.

Features of programming software:

– Support for a wide range of IC devices and programming algorithms

– Intuitive user interface for configuring and controlling the programming process

– Data management capabilities, including file handling and version control

– Integration with other design tools and data formats

– Debugging and troubleshooting features for identifying and resolving programming issues

Best Practices for IC Programming in PCB Assembly

To ensure successful and reliable IC programming in PCB assembly, it is important to follow best practices throughout the process. Here are some key considerations and guidelines:

-

Design for Programmability: When designing the PCB, consider the programming requirements of the ICs. Include necessary programming interfaces, test points, and accessibility features to facilitate efficient programming.

-

Select Appropriate Programming Method: Choose the programming method that best suits your specific requirements. Consider factors such as the IC type, programming interface, production volume, and available resources.

-

Use Reliable Programming Tools and Equipment: Invest in high-quality programming tools and equipment that are compatible with your ICs and PCB Design. Ensure that the tools are well-maintained and calibrated to ensure accurate and reliable programming.

-

Follow Proper Handling Procedures: Handle ICs and PCBs with care during the programming process. Use appropriate static protection measures and follow manufacturer guidelines for handling and storage to prevent damage to the components.

-

Verify Programming Results: Implement robust verification and testing procedures to ensure that the programmed ICs function as intended. Perform functional tests, boundary scan tests, and other relevant checks to validate the programming results.

-

Maintain Version Control: Establish a version control system for the programming data and firmware. Keep track of different versions, changes, and updates to ensure traceability and facilitate debugging and maintenance.

-

Document the Programming Process: Maintain clear and detailed documentation of the programming process, including the programming parameters, software settings, and any specific instructions. This documentation aids in troubleshooting, process repeatability, and knowledge transfer.

-

Train and Qualify Personnel: Ensure that the personnel involved in IC programming are properly trained and qualified. Provide necessary training on the programming tools, processes, and best practices to maintain consistent quality and minimize human errors.

-

Implement Quality Control Measures: Establish quality control measures throughout the programming process. Perform regular audits, inspections, and statistical process control to identify and address any quality issues promptly.

-

Stay Updated with Industry Advancements: Keep abreast of the latest advancements in IC programming technologies, tools, and techniques. Continuously evaluate and adopt new approaches that can improve efficiency, reliability, and cost-effectiveness in your PCB assembly process.

Frequently Asked Questions (FAQ)

-

What is the difference between in-system programming (ISP) and off-board programming?

In-system programming (ISP) is a method where the IC is programmed while it is already soldered onto the PCB, using a programming interface available on the PCB. Off-board programming, on the other hand, involves removing the IC from the PCB and programming it using a standalone programmer or a programming socket before soldering it onto the PCB. -

Can all ICs be programmed using the same programming method?

No, different ICs may require different programming methods based on their type, programming interface, and package. Some ICs may support in-system programming, while others may require off-board programming or specific programming interfaces. It is important to refer to the IC manufacturer’s datasheet and programming guidelines to determine the appropriate programming method for each IC. -

What are the advantages of using programmable ICs in PCB assembly?

Programmable ICs offer several advantages in PCB assembly, including customization, cost-effectiveness, flexibility, and upgradability. They allow designers to implement unique features and optimize performance according to specific application requirements. Programmable ICs also provide the ability to modify or upgrade the functionality of the PCB even after it has been manufactured, reducing the need for hardware modifications. -

How does IC programming impact the overall PCB assembly process?

IC programming is a critical step in the PCB assembly process. It ensures that the ICs are configured with the desired functionality and parameters before they are soldered onto the PCB. Proper IC programming is essential for the overall functionality and reliability of the PCB. It can impact the assembly time, cost, and quality, depending on the programming method and the complexity of the ICs involved. -

What should I consider when selecting programming tools and equipment for IC programming?

When selecting programming tools and equipment, consider factors such as compatibility with your ICs and PCB design, programming speed, reliability, ease of use, and cost. Ensure that the tools support the required programming interfaces and algorithms for your specific ICs. Consider the production volume and the available resources to determine the most suitable programming tools and equipment for your PCB assembly process.

Conclusion

IC programming is a vital aspect of PCB assembly that enables the customization, optimization, and upgradability of electronic devices. By configuring programmable ICs with the desired functionality and parameters, designers can create PCBs that meet specific application requirements and adapt to changing needs.

Understanding the different IC programming methods, tools, and best practices is crucial for ensuring successful and reliable programming in PCB assembly. Whether using in-system programming, off-board programming, or in-circuit programming, selecting the appropriate method and tools based on the specific requirements of the ICs and PCB design is essential.

By following best practices, such as designing for programmability, using reliable programming tools, implementing quality control measures, and staying updated with industry advancements, companies can optimize their IC programming process and achieve high-quality, cost-effective, and efficient PCB assembly.

As technology continues to evolve, the importance of IC programming in PCB assembly will only grow. Embracing the latest advancements in programming techniques, tools, and methodologies will be key to staying competitive and delivering innovative electronic products to the market.

Leave a Reply