Introduction to Rayming-reflow-pilot

Rayming-reflow-pilot is a revolutionary technology that has been gaining traction in the manufacturing industry. It is a process that involves the use of a pilot door to control the flow of molten solder during the reflow soldering process. This technology has been developed to improve the efficiency and reliability of the soldering process, which is a critical step in the manufacturing of electronic components and devices.

How Rayming-reflow-pilot Works

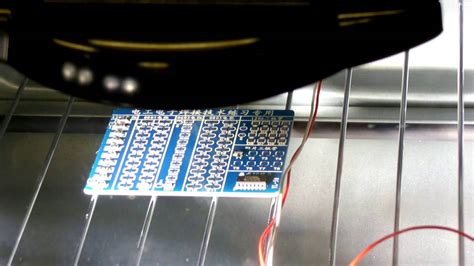

The Rayming-reflow-pilot technology works by using a pilot door to control the flow of molten solder during the reflow soldering process. The pilot door is a small opening that is located at the entrance of the reflow oven. When the printed circuit board (PCB) enters the oven, the pilot door opens to allow the molten solder to flow onto the PCB. The pilot door then closes to prevent the solder from flowing out of the oven.

The pilot door is controlled by a computer system that monitors the temperature and speed of the PCB as it moves through the oven. The computer system adjusts the opening and closing of the pilot door to ensure that the correct amount of solder is applied to the PCB at the right time and temperature.

Benefits of Rayming-reflow-pilot

There are several benefits to using Rayming-reflow-pilot technology in the manufacturing process. Some of the key benefits include:

-

Improved Solder Joint Quality: The pilot door ensures that the correct amount of solder is applied to the PCB at the right time and temperature, which results in higher quality solder joints.

-

Reduced Defects: The pilot door helps to prevent solder bridges and other defects that can occur during the soldering process.

-

Increased Efficiency: The computer-controlled pilot door allows for faster and more accurate soldering, which can increase the overall efficiency of the manufacturing process.

-

Cost Savings: By reducing defects and increasing efficiency, Rayming-reflow-pilot technology can help to reduce overall manufacturing costs.

Rayming-reflow-pilot vs. Traditional Reflow Soldering

Traditional reflow soldering involves the use of a conveyor belt to move the PCB through the oven. The solder is applied to the PCB using a stencil or screen printing process, and the PCB is then heated to melt the solder and form the solder joints.

While traditional reflow soldering has been used for many years, it has several limitations. One of the main limitations is that it can be difficult to control the amount of solder that is applied to the PCB. If too much solder is applied, it can result in solder bridges and other defects. If too little solder is applied, it can result in weak or incomplete solder joints.

Rayming-reflow-pilot technology addresses these limitations by using a pilot door to control the flow of solder onto the PCB. The computer-controlled pilot door ensures that the correct amount of solder is applied at the right time and temperature, which helps to reduce defects and improve the overall quality of the solder joints.

Comparison Table: Rayming-reflow-pilot vs. Traditional Reflow Soldering

| Feature | Rayming-reflow-pilot | Traditional Reflow Soldering |

|---|---|---|

| Solder Application | Pilot door controls solder flow | Stencil or screen printing |

| Defect Rate | Lower | Higher |

| Efficiency | Higher | Lower |

| Cost Savings | Yes | No |

Implementing Rayming-reflow-pilot in Manufacturing

Implementing Rayming-reflow-pilot technology in a manufacturing process requires careful planning and execution. The first step is to assess the current manufacturing process and determine whether Rayming-reflow-pilot technology is a good fit.

Once it has been determined that Rayming-reflow-pilot technology is a good fit, the next step is to select the appropriate equipment and software. The equipment needed for Rayming-reflow-pilot includes a reflow oven with a pilot door, a computer system to control the pilot door, and software to monitor and adjust the soldering process.

After the equipment and software have been selected, the next step is to train the manufacturing staff on how to use the new technology. This includes training on how to operate the equipment, how to program the software, and how to troubleshoot any issues that may arise.

Finally, it is important to monitor the performance of the Rayming-reflow-pilot system over time to ensure that it is working as intended. This may involve collecting data on defect rates, efficiency, and cost savings, and making adjustments as needed to optimize the system.

Case Study: XYZ Electronics

XYZ Electronics is a manufacturer of electronic components and devices. The company was experiencing high defect rates and low efficiency in its soldering process, which was resulting in increased costs and reduced profitability.

To address these issues, XYZ Electronics decided to implement Rayming-reflow-pilot technology in its manufacturing process. The company purchased a new reflow oven with a pilot door, along with a computer system and software to control the pilot door.

After implementing the new technology, XYZ Electronics saw a significant improvement in its soldering process. Defect rates decreased by 50%, and efficiency increased by 30%. The company also saw a 20% reduction in overall manufacturing costs.

Frequently Asked Questions (FAQ)

-

What is Rayming-reflow-pilot technology?

Rayming-reflow-pilot is a technology that uses a pilot door to control the flow of molten solder during the reflow soldering process. The pilot door is controlled by a computer system that monitors the temperature and speed of the PCB as it moves through the oven. -

How does Rayming-reflow-pilot differ from traditional reflow soldering?

Traditional reflow soldering uses a conveyor belt to move the PCB through the oven and applies solder using a stencil or screen printing process. Rayming-reflow-pilot uses a pilot door to control the flow of solder onto the PCB, which helps to reduce defects and improve the overall quality of the solder joints. -

What are the benefits of using Rayming-reflow-pilot technology?

The benefits of using Rayming-reflow-pilot technology include improved solder joint quality, reduced defects, increased efficiency, and cost savings. -

What equipment is needed to implement Rayming-reflow-pilot technology?

To implement Rayming-reflow-pilot technology, a manufacturer needs a reflow oven with a pilot door, a computer system to control the pilot door, and software to monitor and adjust the soldering process. -

How can a manufacturer determine if Rayming-reflow-pilot technology is a good fit for their process?

A manufacturer can assess their current manufacturing process and determine if Rayming-reflow-pilot technology is a good fit by considering factors such as defect rates, efficiency, and cost savings. They may also want to consult with a Rayming-reflow-pilot expert or vendor to get a better understanding of how the technology could benefit their specific process.

Conclusion

Rayming-reflow-pilot technology is a revolutionary approach to reflow soldering that offers significant benefits over traditional methods. By using a pilot door to control the flow of solder onto the PCB, Rayming-reflow-pilot technology helps to reduce defects, improve efficiency, and lower overall manufacturing costs.

While implementing Rayming-reflow-pilot technology requires careful planning and execution, the benefits can be significant. As demonstrated by the case study of XYZ Electronics, manufacturers who adopt this technology can see significant improvements in their soldering process, leading to increased profitability and competitiveness in the market.

As the manufacturing industry continues to evolve, it is likely that more and more companies will adopt Rayming-reflow-pilot technology to stay ahead of the curve. By embracing this innovative approach to soldering, manufacturers can position themselves for success in the years to come.

Leave a Reply