Introduction to PCB Protection

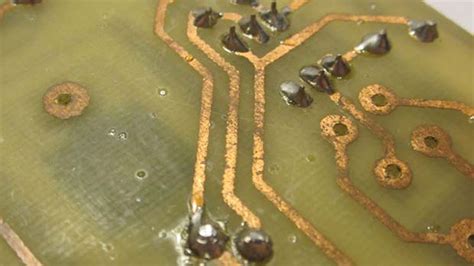

Printed Circuit Boards (PCBs) are essential components in modern electronic devices. They provide a platform for mounting and interconnecting electronic components, enabling the functionality of the device. However, PCBs are susceptible to various environmental factors, such as moisture, dust, and extreme temperatures, which can lead to damage and malfunction. Therefore, it is crucial to implement effective PCB protection measures to ensure the reliability and longevity of electronic devices.

In this article, we will explore various techniques and methods for protecting PCBs from environmental hazards. We will discuss the importance of PCB protection, the common environmental factors that can damage PCBs, and the best practices for safeguarding these critical components.

Why is PCB Protection Important?

PCB protection is essential for several reasons:

-

Reliability: Protecting PCBs from environmental factors ensures that electronic devices function reliably and consistently over their intended lifespan. Unprotected PCBs are more likely to fail, leading to device malfunction and customer dissatisfaction.

-

Longevity: Proper PCB protection measures extend the life of electronic devices by preventing premature failure due to environmental factors. This reduces the need for frequent repairs or replacements, saving costs for both manufacturers and consumers.

-

Safety: In some cases, damaged or malfunctioning PCBs can pose safety risks, such as electrical shocks or fire hazards. Implementing adequate protection measures minimizes these risks and ensures the safety of users.

-

Compliance: Many industries have specific standards and regulations regarding the protection of electronic components, including PCBs. Adhering to these standards is crucial for compliance and to avoid legal and financial consequences.

Common Environmental Factors Affecting PCBs

PCBs are exposed to various environmental factors that can cause damage or deterioration. Some of the most common factors include:

-

Moisture: Humidity and condensation can lead to corrosion of PCB Components and traces, causing short circuits and other electrical issues. Moisture can also promote the growth of mold and other contaminants that can further damage the PCB.

-

Dust and Debris: Dust, dirt, and other particulate matter can accumulate on PCBs, leading to insulation breakdown, short circuits, and overheating. These contaminants can also interfere with the proper functioning of moving parts, such as switches and connectors.

-

Temperature Extremes: Both high and low temperatures can adversely affect PCBs. High temperatures can cause thermal expansion and stress on components, leading to cracking and delamination of the PCB substrate. Low temperatures can cause condensation and embrittlement of components, making them more susceptible to damage.

-

Vibration and Shock: Mechanical stresses, such as vibration and shock, can cause components to become loose or dislodged from the PCB. This can lead to intermittent connections, short circuits, and other electrical issues.

-

Chemical Exposure: Exposure to chemicals, such as solvents, oils, and cleaning agents, can degrade the PCB substrate and components. Some chemicals can also cause corrosion or dissolve the protective coatings on PCBs.

Best Practices for PCB Protection

To effectively protect PCBs from environmental factors, several best practices can be implemented:

1. Conformal Coating

Conformal coating is a process where a thin, protective layer is applied to the surface of the PCB. This layer acts as a barrier against moisture, dust, and other contaminants. There are various types of conformal coatings, each with its own advantages and limitations:

| Coating Type | Advantages | Disadvantages |

|---|---|---|

| Acrylic | Easy to apply and repair, good moisture resistance | Limited temperature range, poor chemical resistance |

| Silicone | Wide temperature range, good flexibility | Difficult to repair, can trap contaminants |

| Polyurethane | Good abrasion and chemical resistance | Requires specialized application equipment |

| Epoxy | Excellent chemical and abrasion resistance | Difficult to repair, requires high cure temperatures |

| Parylene | Uniform coverage, excellent barrier properties | Expensive, requires specialized vacuum deposition equipment |

When selecting a conformal coating, consider the specific environmental factors the PCB will be exposed to and choose a coating that provides the necessary protection.

2. Encapsulation

Encapsulation involves completely surrounding the PCB with a protective material, such as epoxy or silicone. This provides a higher level of protection compared to conformal coating, as it seals the PCB from all sides. Encapsulation is particularly useful for PCBs exposed to harsh environments or those requiring a high degree of mechanical protection.

There are two main methods of encapsulation:

-

Potting: The PCB is placed in a mold, and the encapsulant material is poured over it, filling all voids and creating a solid block around the PCB.

-

Overmolding: The PCB is placed in a mold, and a thermoplastic or thermoset material is injected around it, forming a protective shell.

Encapsulation provides excellent protection against moisture, dust, and mechanical stresses. However, it can make repairs and modifications more difficult, as the encapsulant material must be removed to access the PCB.

3. Proper PCB Design

Designing PCBs with protection in mind can greatly enhance their resilience against environmental factors. Some design considerations include:

-

Selecting appropriate materials: Choose PCB Substrates and components that are rated for the expected environmental conditions, such as temperature range and humidity levels.

-

Providing adequate spacing: Ensure sufficient spacing between components and traces to minimize the risk of short circuits and to allow for proper cleaning and coating application.

-

Implementing seal-off zones: Designate areas on the PCB where conformal coating or encapsulation should not be applied, such as connectors or test points. This can be achieved using Solder Mask or other masking materials.

-

Incorporating strain relief: Use strain relief features, such as cable ties or brackets, to minimize mechanical stress on components and connections.

4. Environmental Testing

Conducting environmental testing on PCBs is crucial to ensure their reliability and durability. Some common tests include:

-

Temperature cycling: Exposing the PCB to alternating high and low temperatures to simulate thermal stress.

-

Humidity testing: Subjecting the PCB to high humidity levels to assess its moisture resistance.

-

Vibration and shock testing: Applying mechanical stresses to the PCB to evaluate its resilience against vibration and impact.

-

Salt spray testing: Exposing the PCB to a salt spray environment to assess its corrosion resistance.

By conducting these tests, manufacturers can identify potential weaknesses in the PCB design or protection measures and make necessary improvements before mass production.

5. Proper Handling and Storage

Proper handling and storage of PCBs are essential to maintain their integrity and protect them from environmental factors. Some best practices include:

-

Using ESD protection: Implement electrostatic discharge (ESD) protection measures, such as grounded workstations and ESD-safe packaging, to prevent damage from static electricity.

-

Controlling humidity: Store PCBs in a controlled environment with low humidity to minimize the risk of moisture-related damage. Use desiccant packs or humidity-controlled cabinets when necessary.

-

Avoiding contamination: Handle PCBs in a clean environment and use lint-free gloves to prevent contamination from oils, dust, and other particles.

-

Proper packaging: Use anti-static, moisture-resistant packaging materials to protect PCBs during storage and transportation.

FAQ

-

What is the most common cause of PCB failure?

The most common cause of PCB failure is exposure to moisture, which can lead to corrosion and short circuits. -

Can conformal coating be applied to all types of PCBs?

Conformal coating can be applied to most types of PCBs, but some components, such as connectors or switches, may require masking to prevent the coating from interfering with their function. -

Is encapsulation always necessary for PCB protection?

Encapsulation is not always necessary and depends on the specific environmental factors the PCB will be exposed to. In some cases, conformal coating or proper PCB design may provide sufficient protection. -

How often should environmental testing be performed on PCBs?

The frequency of environmental testing depends on the industry and the criticality of the application. It is typically performed during the design and validation stages, as well as periodically during production to ensure consistency and reliability. -

Can damaged PCBs be repaired?

In some cases, damaged PCBs can be repaired, depending on the extent and nature of the damage. However, repairs may not always be feasible or cost-effective, and replacement may be necessary.

Conclusion

Protecting PCBs from environmental factors is crucial for ensuring the reliability, longevity, and safety of electronic devices. By implementing best practices such as conformal coating, encapsulation, proper PCB design, environmental testing, and proper handling and storage, manufacturers can significantly reduce the risk of PCB failure and extend the lifespan of their products.

As technology continues to advance and electronic devices become more complex, the importance of PCB protection will only continue to grow. By staying informed about the latest protection methods and technologies, manufacturers can stay ahead of the curve and deliver high-quality, reliable products to their customers.

Leave a Reply