What is a PCB CNC Machine?

A PCB CNC machine is a computer-controlled device designed specifically for the manufacturing of printed circuit boards. These machines use a combination of cutting tools, drills, and other specialized equipment to create the intricate patterns and holes required for PCB Fabrication. CNC machines are programmed with specific instructions, known as G-code, which guide the tools to precisely cut, drill, and route the PCB substrate according to the designed layout.

Benefits of Using PCB CNC Machines

The use of CNC machines in PCB manufacturing offers several significant advantages over traditional manual methods:

-

Precision and Accuracy: CNC machines are capable of producing highly precise and accurate PCBs, with tolerances as low as a few microns. This level of precision is essential for modern electronics, where even the slightest deviation can lead to malfunction or failure.

-

Increased Efficiency: CNC machines can work continuously, 24/7, without the need for breaks or rest periods. This enables manufacturers to produce PCBs at a much faster rate compared to manual methods, reducing lead times and increasing overall productivity.

-

Consistency and Repeatability: Once a PCB design is programmed into the CNC machine, it can be replicated countless times with identical results. This consistency is crucial for maintaining quality standards and ensuring that each PCB meets the required specifications.

-

Cost-Effectiveness: While the initial investment in a PCB CNC machine may be higher than traditional manual methods, the long-term cost savings are significant. The increased efficiency, reduced labor costs, and minimized material waste all contribute to a more cost-effective manufacturing process.

Types of PCB CNC Machines

There are several types of PCB CNC machines, each designed for specific tasks in the manufacturing process:

1. Drilling Machines

PCB Drilling machines are used to create the holes required for component placement and interconnection. These machines use high-speed spindles and specialized drill bits to create precise holes in the PCB substrate. Modern CNC drilling machines can create thousands of holes per minute, with diameters as small as 0.1mm.

| Feature | Specification |

|---|---|

| Spindle Speed | Up to 200,000 RPM |

| Drilling Accuracy | ±0.02mm |

| Minimum Hole Diameter | 0.1mm |

| Maximum Drilling Speed | 1,000 holes/min |

2. Routing Machines

PCB routing machines are used to cut and shape the outline of the PCB, as well as create any required internal cutouts or slots. These machines use high-speed spindles and cutting tools to remove excess material from the PCB substrate. CNC routing machines offer high precision and can create complex shapes and contours.

| Feature | Specification |

|---|---|

| Spindle Speed | Up to 60,000 RPM |

| Routing Accuracy | ±0.05mm |

| Minimum Routing Width | 0.2mm |

| Maximum Routing Speed | 5,000mm/min |

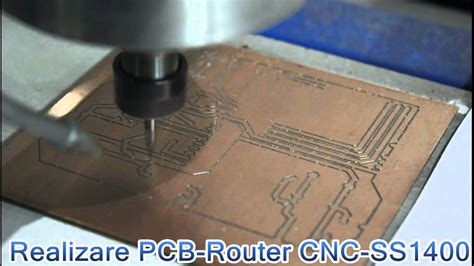

3. Milling Machines

PCB Milling machines are used for the removal of excess copper from the PCB substrate, creating the required traces and pads for component placement. These machines use high-speed spindles and specialized milling tools to remove the unwanted copper, leaving behind the desired circuit pattern. CNC milling machines offer high accuracy and can create fine-pitch traces and pads.

| Feature | Specification |

|---|---|

| Spindle Speed | Up to 100,000 RPM |

| Milling Accuracy | ±0.01mm |

| Minimum Trace Width | 0.1mm |

| Maximum Milling Speed | 2,000mm/min |

4. Laser Machines

PCB laser machines use high-powered lasers to create the required traces and pads on the PCB substrate. These machines offer several advantages over traditional mechanical methods, including higher precision, faster processing speeds, and the ability to create finer traces and pads. Laser machines are particularly well-suited for high-density PCB designs and can create traces with widths as small as 25 microns.

| Feature | Specification |

|---|---|

| Laser Type | UV Laser |

| Laser Wavelength | 355nm |

| Minimum Trace Width | 25μm |

| Maximum Processing Speed | 1,000mm/s |

The PCB CNC Manufacturing Process

The PCB manufacturing process using CNC machines typically involves the following steps:

-

Design and Layout: The PCB design is created using specialized software, such as Eagle or Altium Designer. The design includes the circuit schematic, component placement, and trace routing.

-

Gerber File Generation: Once the design is finalized, Gerber files are generated. These files contain the necessary information for the CNC machines to fabricate the PCB, including the layer stackup, drill locations, and copper patterns.

-

Material Preparation: The PCB substrate material, typically FR-4, is cut to the required size and cleaned to remove any contaminants.

-

Drilling: The PCB substrate is loaded into the CNC drilling machine, which creates the required holes for component placement and interconnection.

-

Copper Patterning: The drilLED PCB substrate is then processed by the CNC milling or laser machine, which removes the unwanted copper, leaving behind the desired circuit pattern.

-

Lamination: If the PCB design requires multiple layers, the individual layers are aligned and laminated together under high pressure and temperature.

-

Surface Finishing: The exposed copper on the PCB is coated with a protective layer, such as solder mask or silkscreen, to prevent oxidation and improve solderability.

-

Quality Control: The finished PCB undergoes a series of quality control checks, including visual inspection, electrical testing, and functional testing, to ensure that it meets the required specifications.

Advantages of High-Tech PCB CNC Machines

The use of high-tech CNC machines in PCB manufacturing offers several key advantages:

-

Miniaturization: As electronic devices become smaller and more compact, the demand for high-density PCBs with fine-pitch traces and components increases. High-tech CNC machines, particularly laser machines, are capable of creating these ultra-fine features, enabling the production of miniaturized PCBs for advanced applications.

-

High-Speed Manufacturing: Advanced CNC machines offer significantly faster processing speeds compared to traditional methods. This enables manufacturers to produce PCBs at a much higher rate, reducing lead times and increasing overall output.

-

Improved Reliability: The high precision and accuracy offered by CNC machines result in PCBs with fewer defects and higher reliability. This is particularly important for critical applications, such as aerospace, medical devices, and automotive electronics.

-

Reduced Environmental Impact: CNC machines offer a more environmentally friendly approach to PCB manufacturing. The increased efficiency and reduced material waste contribute to a lower environmental impact compared to traditional methods.

Frequently Asked Questions (FAQ)

1. What is the minimum feature size that can be achieved with PCB CNC machines?

The minimum feature size depends on the specific type of CNC machine being used. Laser machines are capable of creating traces and pads as small as 25 microns, while mechanical machines, such as drilling and milling machines, typically have a minimum feature size of around 100 microns.

2. Can PCB CNC machines handle multi-layer PCBs?

Yes, advanced PCB CNC machines are capable of handling multi-layer PCBs. The individual layers are processed separately and then laminated together under high pressure and temperature to create the final multi-layer PCB.

3. What materials can be processed by PCB CNC machines?

PCB CNC machines are primarily designed to process FR-4, which is the most common PCB substrate material. However, some machines can also handle other materials, such as aluminum, copper, and ceramic substrates.

4. How long does it take to manufacture a PCB using CNC machines?

The manufacturing time depends on the complexity of the PCB design and the specific machines being used. However, thanks to the high-speed processing capabilities of modern CNC machines, PCBs can typically be manufactured in a matter of hours, compared to days or even weeks with traditional manual methods.

5. Are PCB CNC machines suitable for prototyping and low-volume production?

Yes, PCB CNC machines are well-suited for prototyping and low-volume production. The high precision and fast processing speeds of these machines enable manufacturers to quickly produce high-quality PCB Prototypes and small production runs, without the need for expensive tooling or setup costs.

Conclusion

The advent of high-tech PCB CNC machines has revolutionized the electronics manufacturing industry. These advanced machines offer unparalleled precision, efficiency, and reliability, enabling the production of complex, high-density PCBs for a wide range of applications. As electronic devices continue to evolve and become more sophisticated, the role of PCB CNC machines in the manufacturing process will only continue to grow. By embracing these cutting-edge technologies, manufacturers can stay ahead of the curve and deliver the innovative, high-quality products that customers demand.

Leave a Reply