Introduction to Flex PCB Soldering

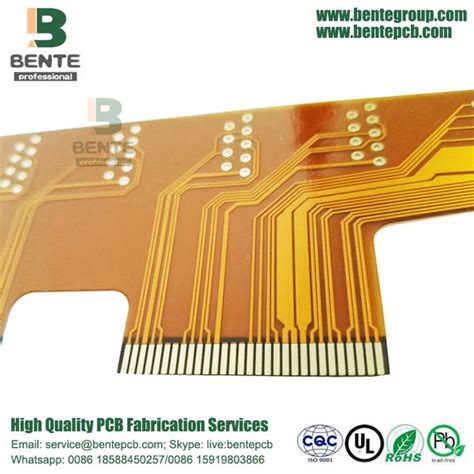

Flexible printed circuit boards, or flex PCBs, have gained widespread popularity in recent years due to their versatility and ability to fit into compact spaces. These circuits consist of a thin, flexible substrate with conductive traces and components mounted on the surface. One of the critical aspects of manufacturing flex PCBs is the soldering process, particularly when dealing with surface mount devices (SMDs). Proper soldering techniques ensure reliable electrical connections and the overall durability of the Flex PCB Assembly.

In this article, we will discuss five essential factors you need to pay attention to when soldering SMDs on flex PCBs. By understanding and implementing these considerations, you can achieve high-quality soldering results and minimize potential issues during the assembly process.

1. Material Selection and Compatibility

Choosing the Right Flex PCB Material

When it comes to flex PCB soldering, the choice of materials plays a crucial role in the success of the assembly process. The most common materials used for flex PCBs include:

- Polyimide (PI): Known for its excellent thermal stability and mechanical properties, polyimide is the most widely used substrate material for flex PCBs.

- Polyester (PET): PET offers good flexibility and electrical properties, making it suitable for applications with less demanding requirements.

- Flexible Copper-Clad Laminates (FCCL): FCCLs consist of a thin layer of copper bonded to a flexible dielectric material, providing a conductive layer for circuit traces.

It is essential to select the appropriate material based on the specific requirements of your application, such as temperature tolerance, flexibility, and electrical performance.

Solder Paste and Flux Compatibility

In addition to the flex PCB material, you must also consider the compatibility of the solder paste and flux used during the soldering process. The solder paste should have the appropriate melting temperature and rheology to ensure proper wetting and formation of solder joints. The flux, which helps remove oxides and promote solder flow, should be compatible with the flex PCB material and not cause any degradation or delamination.

When selecting solder paste and flux, consider the following factors:

- Alloy composition: Choose a solder alloy that meets the temperature requirements of your application and complies with any industry standards or regulations.

- Particle size: The particle size of the solder paste should be suitable for the pitch and size of the SMD components being soldered.

- Flux activity: Select a flux with the appropriate activity level based on the surface finish of the flex PCB and the cleanliness of the components.

2. Thermal Management

Controlling Soldering Temperature

One of the primary challenges in flex PCB soldering is managing the temperature during the soldering process. Flex PCBs are more sensitive to heat compared to rigid PCBs due to their thin and flexible nature. Excessive heat can cause warping, delamination, or damage to the flex PCB material.

To control the soldering temperature, consider the following techniques:

- Use a temperature-controlled soldering iron: A soldering iron with adjustable temperature settings allows you to set the appropriate temperature for the specific solder alloy and components being used.

- Implement a thermal profile: Develop a thermal profile that defines the ramp-up rate, peak temperature, and cooling rate for the soldering process. This helps ensure consistent and controlled heating of the flex PCB.

- Monitor the temperature: Use a thermocouple or infrared thermometer to monitor the actual temperature of the solder joint during the soldering process. Make adjustments as necessary to maintain the desired temperature range.

Minimizing Thermal Stress

In addition to controlling the soldering temperature, it is crucial to minimize thermal stress on the flex PCB during the soldering process. Thermal stress can lead to warping, cracking, or delamination of the flex PCB material.

To minimize thermal stress, consider the following strategies:

- Use a low-temperature solder alloy: Select a solder alloy with a lower melting temperature to reduce the overall heat exposure to the flex PCB.

- Implement pre-heating: Pre-heat the flex PCB and components before soldering to reduce the temperature gradient and minimize thermal shock.

- Use a heat sink: Place a heat sink or thermal management device near the soldering area to dissipate excess heat and prevent localized overheating.

3. Handling and Fixturing

Proper Handling Techniques

Flex PCBs require careful handling during the soldering process to prevent damage or contamination. Improper handling can lead to bending, creasing, or stretching of the flex PCB, which can affect its functionality and reliability.

To ensure proper handling of flex PCBs, follow these guidelines:

- Use clean, lint-free gloves: Wear clean gloves when handling flex PCBs to avoid transferring oils, dirt, or other contaminants to the surface.

- Avoid excessive bending or twisting: Handle flex PCBs gently and avoid sharp bends or twists that can damage the conductive traces or cause delamination.

- Support the flex PCB: Provide adequate support for the flex PCB during handling and soldering to prevent sagging or unintended movement.

Fixturing for Stability

Fixturing plays a vital role in ensuring the stability and alignment of the flex PCB and components during the soldering process. Proper fixturing helps maintain the desired position and orientation of the components, preventing shifting or misalignment.

Consider the following fixturing techniques:

- Use a dedicated fixture: Design and fabricate a custom fixture that holds the flex PCB and components securely in place during soldering. The fixture should accommodate the specific shape and dimensions of the flex PCB.

- Implement temporary adhesives: Use temporary adhesives or tapes to hold the components in place on the flex PCB during soldering. Ensure that the adhesives are compatible with the soldering process and can be easily removed afterward.

- Employ mechanical clamping: Utilize mechanical clamping devices or weights to hold the flex PCB and components in position during soldering. Ensure that the clamping force is sufficient to prevent movement but not excessive to cause damage.

4. Solder Joint Inspection and Quality Control

Visual Inspection

After soldering, it is essential to perform a visual inspection of the solder joints to identify any defects or issues. Visual inspection helps catch problems early in the process and allows for timely corrective actions.

When conducting a visual inspection, look for the following characteristics:

- Solder joint shape: Check if the solder joints have a smooth, concave shape with no excessive solder or insufficient wetting.

- Solder joint size: Ensure that the solder joints are of the appropriate size and do not exhibit excessive or insufficient solder.

- Solder bridges or shorts: Inspect for any solder bridges or shorts between adjacent pads or traces.

- Component alignment: Verify that the components are properly aligned and centered on their respective pads.

Electrical Testing

In addition to visual inspection, electrical testing is crucial to verify the functionality and reliability of the soldered flex PCB assembly. Electrical testing helps identify any open circuits, short circuits, or other connectivity issues.

Consider the following electrical testing methods:

- Continuity testing: Use a multimeter or continuity tester to check the electrical continuity between the desired points on the flex PCB.

- Resistance measurement: Measure the resistance of the solder joints to ensure they are within the acceptable range and do not exhibit excessive resistance.

- Functional testing: Perform functional testing of the assembled flex PCB to verify that it operates as intended and meets the specified performance requirements.

5. Cleaning and Protection

Flux Residue Removal

After soldering, it is important to clean the flex PCB assembly to remove any flux residue or contaminants. Flux residue can lead to corrosion, electrical leakage, or other reliability issues if left on the surface.

To clean the flex PCB, follow these steps:

- Select an appropriate cleaning solution: Choose a cleaning solution that is compatible with the flex PCB material and the type of flux used during soldering. Common cleaning solutions include isopropyl alcohol (IPA) and specialized PCB cleaners.

- Apply the cleaning solution: Use a lint-free cloth, brush, or spray to apply the cleaning solution to the flux residue areas on the flex PCB.

- Agitate and remove the residue: Gently agitate the cleaning solution to dissolve and remove the flux residue. Use a soft brush or swab to dislodge any stubborn residue.

- Rinse and dry: Rinse the flex PCB with deionized water to remove any remaining cleaning solution and residue. Dry the flex PCB using compressed air or a lint-free cloth.

Conformal Coating and Protection

To enhance the protection and durability of the flex PCB assembly, consider applying a conformal coating or encapsulation. Conformal coatings provide a thin, protective layer over the flex PCB and components, shielding them from environmental factors such as moisture, dust, and contaminants.

When selecting a conformal coating, consider the following factors:

- Compatibility: Ensure that the conformal coating is compatible with the flex PCB material, components, and the intended operating environment.

- Application method: Choose a conformal coating that can be applied using the desired method, such as spraying, dipping, or brushing.

- Curing process: Consider the curing requirements of the conformal coating, including the curing time, temperature, and any additional equipment needed.

Frequently Asked Questions (FAQ)

1. What is the recommended soldering temperature for flex PCBs?

The recommended soldering temperature for flex PCBs varies depending on the specific solder alloy and the components being used. Generally, a lower soldering temperature is preferred to minimize thermal stress on the flex PCB material. Consult the solder alloy manufacturer’s specifications and the component datasheets for the recommended soldering temperature range.

2. Can I use the same soldering techniques for flex PCBs as for rigid PCBs?

While some soldering techniques may be similar, flex PCBs require additional considerations and precautions compared to rigid PCBs. Flex PCBs are more sensitive to heat and mechanical stress, so it is essential to use appropriate temperature control, handling techniques, and fixturing methods specifically tailored for flex PCBs.

3. How do I prevent warping or delamination of flex PCBs during soldering?

To prevent warping or delamination of flex PCBs during soldering, employ proper thermal management techniques. Use a low-temperature solder alloy, implement pre-heating, and use a heat sink to dissipate excess heat. Additionally, handle the flex PCB gently and avoid excessive bending or twisting during the soldering process.

4. What should I do if I encounter solder bridges or shorts during inspection?

If you identify solder bridges or shorts during visual inspection, you can use a soldering iron with a fine tip to carefully remove the excess solder. Apply flux to the affected area and gently touch the soldering iron to the solder bridge, allowing the solder to wick onto the iron tip. Repeat the process until the solder bridge is eliminated. Be cautious not to apply excessive heat or pressure, which could damage the flex PCB or components.

5. Is conformal coating always necessary for flex PCB assemblies?

Conformal coating is not always necessary for flex PCB assemblies, but it is highly recommended in environments where the flex PCB will be exposed to moisture, dust, or other contaminants. Conformal coating provides an additional layer of protection and helps improve the reliability and longevity of the flex PCB assembly. However, if the flex PCB will be used in a controlled environment and is not subject to harsh conditions, conformal coating may not be required.

Conclusion

Soldering SMDs on flex PCBs requires careful attention to material selection, thermal management, handling, inspection, and protection. By understanding and implementing the five key considerations discussed in this article, you can achieve high-quality soldering results and ensure the reliability of your flex PCB assemblies.

Remember to choose compatible materials, control the soldering temperature, handle the flex PCB with care, perform thorough inspections, and clean and protect the assembly as needed. By following these guidelines and continuously refining your soldering techniques, you can successfully tackle the challenges of flex PCB soldering and create robust and reliable electronic devices.

Leave a Reply