What is PCBA Testing?

PCBA stands for Printed Circuit Board Assembly. PCBA Testing, also known as PCB Assembly testing or just board testing, is the process of checking a circuit board after all the components have been soldered onto it. The goal is to verify the board was assembled correctly and that it functions as intended before moving forward with installation into the end product.

PCBA testing is a critical step in electronics manufacturing to ensure quality control, identify defects early, and avoid costly rework down the line. Thorough testing can find issues like incorrect component placement, cold solder joints, short circuits, and missing parts that could lead to malfunctions or even safety hazards in the finished device.

The testing process typically involves a combination of automated optical inspection (AOI), x-ray inspection, in-circuit testing (ICT), flying probe tests, boundary scan testing, and functional testing. The exact mix of test methods used depends on the specific board design, component types, reliability requirements, and production volume.

Why is PCBA Testing Important?

PCBA testing is essential for several key reasons:

-

Quality Assurance – Checking that boards meet specifications and function properly before shipping to customers. This upholds brand reputation.

-

Early Defect Detection – Finding and fixing problems during assembly instead of after installation reduces scrap and rework.

-

Regulatory Compliance – Ensuring products comply with relevant safety and performance standards. Failed compliance can lead to recalls or legal issues.

-

Cost Savings – Minimizing the chance of delivering faulty products that require returns, repairs, or replacements under warranty.

-

Time-to-Market – Streamlining testing and minimizing late-stage redesigns accelerates product launch schedules.

In short, a robust PCBA test plan is a must for any electronics manufacturer that values quality, efficiency, and customer satisfaction. Skipping or shortchanging board testing is risky and short-sighted.

Types of PCBA Tests

There are many methods available for testing PCB assemblies, each with its own strengths and limitations. Common types of PCBA tests include:

Automated Optical Inspection (AOI)

AOI uses high-resolution cameras and computer vision algorithms to quickly scan the board and identify defects like misaligned components, solder bridges, or incorrect parts. It excels at catching cosmetic and placement issues but cannot test actual functionality.

| Pros | Cons |

|---|---|

| Fast | Limited to visible defects |

| Non-contact | Requires programming for each design |

| Relatively low cost | Cannot verify values or functionality |

X-Ray Inspection

X-ray systems can see through the board to inspect solder joints, even under BGA chips and other hidden areas. They are useful for finding voids, head-in-pillow defects, and other flaws not visible to AOI.

| Pros | Cons |

|---|---|

| Sees hidden solder joints | Relatively slow |

| Detects internal voids/cracks | Higher equipment cost |

| Handles double-sided boards | Radiation safety protocols needed |

In-Circuit Test (ICT)

ICT uses a bed-of-nails fixture to access test points across the powered board. It can measure component values, test basic functionality, and compare against a known-good reference. ICT provides more thorough screening than AOI but requires upfront investment in fixtures.

| Pros | Cons |

|---|---|

| Tests component values | Requires custom test fixtures |

| Detects missing/wrong parts | Can damage boards if not careful |

| Finds some functional faults | Limited access to miniaturized designs |

Flying Probe Test

Flying probe testers use robotic arms with movable test pins instead of a fixed bed-of-nails. This provides ICT-like coverage without needing custom fixtures. Programming is still required but overall cost and changeover time are reduced.

| Pros | Cons |

|---|---|

| No unique test fixtures | Slower than dedicated ICT |

| Flexible for design changes | More expensive than basic AOI |

| Detects open/short circuits | Still requires test point access |

Boundary Scan Test

Boundary scan embeds test circuitry right into chips that support JTAG or similar standards. It allows checking interconnects and logic between devices by feeding in test patterns and instructions through a simple 4-5 wire interface. Powerful but requires design-for-test practices.

| Pros | Cons |

|---|---|

| Tests interconnects and I/O | Requires JTAG-enabled chips |

| Finds some logical faults | Extra design effort needed |

| Needs minimal physical access | Specialized skills to implement |

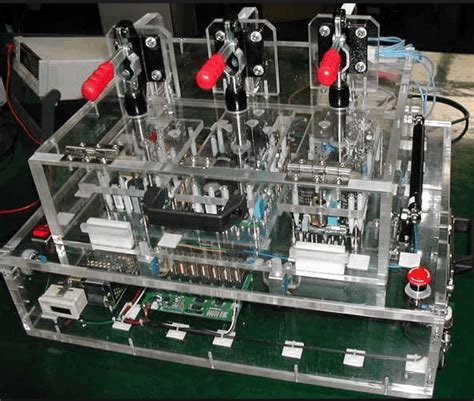

Functional Test

Functional testing focuses on validating board operation under real-world conditions. The board is put in a test fixture that mimics its final enclosure and subjected to normal input signals and loads. Functional tests are highly specific to each product and aim to catch any defects that slipped through prior screens.

| Pros | Cons |

|---|---|

| Verifies actual operation | Requires unique test setups |

| Closest to end-use | May not pinpoint root cause |

| Last line of defense | Time consuming to develop |

Developing a PCBA Test Strategy

With all the options available, selecting the optimal combination of PCBA test methods can seem daunting. The key is to understand the tradeoffs and align the test approach with your specific needs. Here are some factors to consider:

-

Product Complexity – More complex boards with dense layouts, fine-pitch components and high layer counts benefit from advanced techniques like X-ray, flying probe and boundary scan to maintain high fault coverage. Simpler designs may get by with just AOI and basic functional checks.

-

Reliability Requirements – Products with stringent reliability needs, such as medical, automotive, aerospace, or military applications, often require extensive testing to meet relevant standards and certifications. Consumer goods may have more flexibility.

-

Production Volume – High-volume products can justify investing in automated solutions like dedicated ICT fixtures that have high upfront costs but low per-unit test times. Low-volume or prototype runs are better suited for flying probe or manual functional testing.

-

Time-to-Market Goals – Aggressive product launch timelines may necessitate a streamlined test approach that emphasizes catching major faults quickly. Boundary scan and functional tests tend to have longer development cycles.

-

Budget Constraints – Comprehensive PCBA testing can require significant capital equipment investment and engineering resources. Work within your means to get the best possible quality within practical limits.

A phased approach often works well, ramping up test coverage through the product lifecycle. During prototyping, rely on manual inspection and basic functional checks. For pilot production, introduce AOI and/or flying probe to screen for common manufacturing defects. As you scale to full production, consider adding ICT or boundary scan to drive down field failures and give a full functional test to a sample of boards. Fine-tune your process over time based on results.

Best Practices for PCBA Test

Regardless of the specific test methods used, there are some general best practices that can help streamline your PCBA test process and get the most value from it:

-

Design for Testability – Consider test needs early in the design process. Add test points, JTAG interfaces, and other features that enable efficient testing. Follow design-for-manufacturing (DFM) guidelines to minimize defect opportunities.

-

Leverage Test Coverage Analysis – Use software tools to analyze your board design and identify test coverage gaps. Aim for the highest practical fault detection given your time and budget constraints.

-

Implement a Robust Defect Tracking System – Record and analyze all defects found during testing. Use this data to identify trends, root causes, and improvement opportunities. Share learnings with the design and process engineering teams.

-

Optimize Test Sequence – Start with quick, low-cost methods like AOI to weed out major defects early. Progress to more in-depth functional tests on a sample basis. Strike a balance between minimizing test time and maximizing coverage.

-

Regularly Review and Update Test Plans – As products evolve and new failure modes emerge, update your test approach accordingly. Seek opportunities to automate manual checks and introduce new tools that could boost efficiency.

-

Train and Cross-Train Technicians – Develop in-house expertise on your selected PCBA test solutions. Have multiple technicians trained on each method to avoid bottlenecks. Foster a culture of continuous improvement.

-

Partner with Experienced Suppliers – Work with PCB fabrication and assembly partners that have robust testing capabilities. Lean on their expertise to optimize your test strategy. Consider outsourcing some testing if cost-effective.

By taking a proactive, data-driven approach to PCBA testing, you can deliver high-quality products with confidence while keeping costs and cycle times in check. It’s an investment that pays off in customer satisfaction and long-term success.

PCBA Test FAQ

Q: How much does PCBA testing cost?

A: The cost of PCBA testing varies widely based on the methods used, board complexity, volume, and other factors. AOI and flying probe systems can range from tens to hundreds of thousands of dollars. Dedicated ICT fixtures can cost thousands per board design. Expect to budget several dollars per board in consumables and labor to operate the test systems. Work with an experienced test partner to model costs for your situation.

Q: How long does PCBA testing take?

A: Test time depends on the specific methods used and the size of the board. AOI can scan a board in a few seconds. Flying probe tests may take a few minutes per board. Manual functional tests can take several minutes. Parallel testing multiple boards can increase throughput. In general, allocate a few minutes per board on average and scale up as needed.

Q: Can PCBA testing catch every possible defect?

A: While a comprehensive test strategy aims for maximum fault coverage, no set of tests is perfect. Some defects, like intermittent faults or subtle performance issues, may slip through to the end product. However, a robust test process will catch the vast majority of manufacturing defects and significantly reduce field failure rates. Combine PCBA testing with good design practices and ongoing reliability monitoring for best results.

Q: How often should PCBA tests be performed?

A: In general, every board should be tested at some level before shipping to the customer. A common approach is 100% AOI, sample-based ICT, and Soak Testing on a small percentage of boards. Tweak sampling rates based on actual defect levels. Increase testing if quality issues arise or for critical applications. Work with your suppliers to establish an efficient test flow that meets your needs.

Q: What skills are needed for PCBA testing?

A: PCBA test development and operation requires a mix of electrical engineering, programming, and mechanical skills. Technicians need to understand the board design, be able to operate the test equipment, diagnose failures, and make repairs. They may need to write test scripts, design fixtures, and analyze data. Look for individuals with a strong electronics background, attention to detail, and problem-solving abilities. Provide training on your specific test systems and processes.

Conclusion

PCBA testing is a vital part of the electronics manufacturing process, ensuring that products meet quality, reliability, and performance expectations. By selecting the right mix of test methods, designing for testability, and implementing best practices, you can ship with confidence and delight your customers. Don’t overlook this critical step – the success of your products depends on it.

Leave a Reply