Introduction to Multilayer PCB Fabrication

Multilayer Printed Circuit Boards (PCBs) are essential components in modern electronics, enabling the creation of complex and compact devices. The fabrication process of multilayer PCBs involves several intricate steps, each of which can potentially introduce problems that affect the quality, reliability, and functionality of the final product. In this article, we will discuss seven common problems encountered in the multilayer PCB fabrication process and provide insights on how to mitigate or avoid them.

Problem 1: Layer Misalignment

Causes and Consequences

One of the most critical issues in multilayer PCB fabrication is layer misalignment. This problem occurs when the layers of the PCB are not precisely aligned during the lamination process, resulting in improper connections between layers and potential short circuits. Layer misalignment can be caused by several factors, including:

– Incorrect registration of layers during the layup process

– Improper handling of layers during transportation or storage

– Uneven pressure or temperature during the lamination process

Misaligned layers can lead to a range of problems, such as:

– Open or short circuits

– Reduced signal integrity

– Decreased reliability and longevity of the PCB

Solutions and Prevention Measures

To minimize the risk of layer misalignment, PCB manufacturers should:

1. Implement strict quality control measures during the layup process, ensuring proper registration of layers

2. Use automated systems for layer alignment and inspection

3. Maintain consistent environmental conditions (temperature and humidity) during storage and transportation of layers

4. Regularly calibrate and maintain lamination equipment to ensure even pressure and temperature distribution

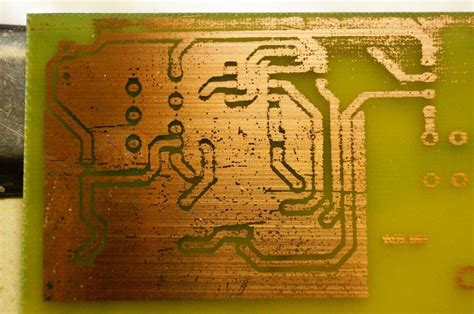

Problem 2: Copper Thickness Variations

Causes and Consequences

Inconsistent copper thickness across the PCB Layers can cause significant issues in the fabrication process and affect the final product’s performance. Copper thickness variations can occur due to:

– Uneven plating during the electroplating process

– Incorrect etching times or concentrations

– Inconsistent surface preparation before plating

Copper thickness variations can lead to:

– Impedance mismatches

– Signal integrity issues

– Reduced current-carrying capacity

– Decreased reliability and longevity of the PCB

Solutions and Prevention Measures

To ensure consistent copper thickness, PCB manufacturers should:

1. Regularly monitor and maintain the electroplating process, ensuring proper chemical concentrations and current density

2. Implement strict process controls for etching, including time, temperature, and etchant concentration

3. Use automated systems for surface preparation and inspection

4. Conduct thorough testing and measurement of copper thickness at various stages of the fabrication process

Problem 3: Drill Misregistration and Breakout

Causes and Consequences

Drill misregistration and breakout are common issues in multilayer PCB fabrication, particularly when dealing with high-density designs. These problems occur when:

– Drill bits are not accurately positioned relative to the PCB Artwork

– Drill bits are worn or damaged, causing them to wander or deflect

– Incorrect drill parameters (speed, feed rate, and retract rate) are used

Drill misregistration and breakout can cause:

– Misaligned or missing vias

– Damaged or severed traces

– Decreased reliability and functionality of the PCB

Solutions and Prevention Measures

To minimize drill misregistration and breakout, PCB manufacturers should:

1. Use high-quality, well-maintained drilling equipment with accurate positioning systems

2. Regularly inspect and replace worn or damaged drill bits

3. Optimize drill parameters based on the material and thickness of the PCB

4. Implement advanced drilling techniques, such as controlled depth drilling or multi-step drilling, for high-density designs

Problem 4: Delamination and Blistering

Causes and Consequences

Delamination and blistering are serious issues that can occur during the multilayer PCB fabrication process, particularly during the lamination and soldering stages. These problems are caused by:

– Inadequate bonding between layers due to contamination or poor surface preparation

– Excessive moisture content in the PCB materials

– Rapid heating or cooling during lamination or soldering

Delamination and blistering can lead to:

– Reduced mechanical strength and durability of the PCB

– Increased risk of short circuits and signal integrity issues

– Premature failure of the PCB in the field

Solutions and Prevention Measures

To prevent delamination and blistering, PCB manufacturers should:

1. Ensure proper surface cleaning and treatment before lamination

2. Use high-quality, low-moisture PCB materials and store them in a controlled environment

3. Implement controlled heating and cooling cycles during lamination and soldering processes

4. Use vacuum lamination techniques to remove trapped air and moisture between layers

Problem 5: Solder Mask Defects

Causes and Consequences

Solder mask defects, such as pinholes, bubbles, or inadequate coverage, can lead to various issues in the multilayer PCB fabrication process. These defects can be caused by:

– Improper application or curing of the solder mask

– Contamination of the PCB surface before solder mask application

– Incompatibility between the solder mask and the PCB material

Solder mask defects can result in:

– Inadequate protection of the PCB surface from environmental factors

– Increased risk of short circuits and signal integrity issues

– Difficulty in soldering components to the PCB

Solutions and Prevention Measures

To minimize solder mask defects, PCB manufacturers should:

1. Use high-quality, compatible solder mask materials

2. Ensure proper surface cleaning and preparation before solder mask application

3. Implement strict process controls for solder mask application and curing

4. Conduct thorough inspections of the solder mask surface for defects

Problem 6: Bow and Twist

Causes and Consequences

Bow and twist are common issues in multilayer PCB fabrication, particularly with thicker boards or asymmetric layer stackups. These problems occur when:

– There is an uneven distribution of copper or dielectric material in the PCB layers

– The PCB is subjected to uneven heating or cooling during the fabrication process

– Improper handling or storage of the PCB causes physical deformation

Bow and twist can lead to:

– Difficulty in assembly and soldering of components

– Reduced reliability and functionality of the PCB

– Increased risk of mechanical stress and failure

Solutions and Prevention Measures

To minimize bow and twist, PCB manufacturers should:

1. Design balanced layer stackups with even distribution of copper and dielectric materials

2. Implement controlled heating and cooling cycles during the fabrication process

3. Use specialized fixtures or press plates to maintain flatness during lamination and cooling

4. Proper handling and storage of the PCB to avoid physical deformation

Problem 7: Contamination and Residues

Causes and Consequences

Contamination and residues on the PCB surface can cause various issues during the multilayer PCB fabrication process and affect the final product’s performance. These problems can be caused by:

– Inadequate cleaning of the PCB surface between fabrication steps

– Use of contaminated or expired chemical solutions

– Improper handling or storage of the PCB in uncontrolled environments

Contamination and residues can lead to:

– Poor adhesion of solder mask or other surface finishes

– Increased risk of short circuits and signal integrity issues

– Reduced reliability and longevity of the PCB

Solutions and Prevention Measures

To minimize contamination and residues, PCB manufacturers should:

1. Implement strict cleaning and maintenance protocols for all equipment and work areas

2. Use high-quality, fresh chemical solutions and regularly monitor their effectiveness

3. Ensure proper handling and storage of the PCB in controlled environments

4. Conduct thorough inspections of the PCB surface for contamination and residues at various stages of the fabrication process

Frequently Asked Questions (FAQ)

-

Q: What is the most critical problem in multilayer PCB fabrication?

A: Layer misalignment is one of the most critical problems in multilayer PCB fabrication, as it can lead to a range of issues, including open or short circuits, reduced signal integrity, and decreased reliability of the PCB. -

Q: How can PCB manufacturers prevent copper thickness variations?

A: To prevent copper thickness variations, PCB manufacturers should regularly monitor and maintain the electroplating process, implement strict process controls for etching, use automated systems for surface preparation and inspection, and conduct thorough testing and measurement of copper thickness at various stages of the fabrication process. -

Q: What causes delamination and blistering in multilayer PCBs?

A: Delamination and blistering in multilayer PCBs can be caused by inadequate bonding between layers due to contamination or poor surface preparation, excessive moisture content in the PCB materials, and rapid heating or cooling during lamination or soldering processes. -

Q: How can bow and twist be minimized in multilayer PCB fabrication?

A: To minimize bow and twist, PCB manufacturers should design balanced layer stackups with even distribution of copper and dielectric materials, implement controlled heating and cooling cycles during the fabrication process, use specialized fixtures or press plates to maintain flatness during lamination and cooling, and ensure proper handling and storage of the PCB to avoid physical deformation. -

Q: What are the consequences of contamination and residues on multilayer PCBs?

A: Contamination and residues on multilayer PCBs can lead to poor adhesion of solder mask or other surface finishes, increased risk of short circuits and signal integrity issues, and reduced reliability and longevity of the PCB.

Conclusion

Multilayer PCB fabrication is a complex process that involves numerous steps, each of which can introduce various problems that affect the quality, reliability, and functionality of the final product. By understanding the causes and consequences of these problems and implementing appropriate solutions and prevention measures, PCB manufacturers can ensure the production of high-quality multilayer PCBs that meet the demanding requirements of modern electronics. Regular monitoring, maintenance, and optimization of the fabrication process, along with strict quality control measures and proper handling and storage of materials, are essential for minimizing the occurrence of these problems and delivering reliable, high-performance multilayer PCBs.

Leave a Reply