What is a Burn-In PCB?

A burn-in printed circuit board (PCB) is a specialized type of PCB designed to undergo a burn-in testing process. Burn-in testing involves subjecting the PCB and its components to elevated temperatures and voltages for an extended period to identify and eliminate early-life failures. This process helps ensure the reliability and longevity of the final product.

Burn-in PCBs are typically used in high-reliability applications, such as aerospace, military, and medical devices, where failure is not an option. These PCBs are designed to withstand the rigors of the burn-in process and provide a reliable platform for testing the attached components.

Characteristics of Burn-In PCBs

Burn-in PCBs have several unique characteristics that set them apart from standard PCBs:

-

High-temperature materials: Burn-in PCBs are made using materials that can withstand elevated temperatures during the burn-in process. This includes the use of high-temperature laminates, such as polyimide or PTFE, and high-temperature solder masks.

-

Robust design: The layout and design of burn-in PCBs are optimized for the burn-in process. This includes the use of larger traces and pads to minimize current density and the incorporation of thermal relief pads to dissipate heat.

-

Component selection: Components used on burn-in PCBs are carefully selected to ensure they can withstand the elevated temperatures and voltages of the burn-in process. This may involve the use of specially-rated components or the addition of heat sinks.

-

Test points: Burn-in PCBs often incorporate additional test points to facilitate monitoring of the board and its components during the burn-in process.

Burn-In PCB Manufacturing Process

The manufacturing process for burn-in PCBs is similar to that of standard PCBs but with additional considerations for the burn-in process:

-

Design: The PCB design is optimized for the burn-in process, taking into account the unique requirements for high-temperature operation and robust performance.

-

Material selection: High-temperature materials, such as polyimide or PTFE laminates and high-temperature solder masks, are selected for the fabrication of the PCB.

-

Fabrication: The PCB is fabricated using standard processes, such as etching, drilling, and plating, but with additional care taken to ensure the integrity of the high-temperature materials.

-

Component assembly: Components are assembled onto the PCB using high-temperature solder and specialized assembly techniques to ensure reliable operation during the burn-in process.

-

Testing: The assembled burn-in PCB undergoes rigorous testing to ensure it meets the required specifications for the burn-in process.

Burn-In PCB Fabricators

Several manufacturers and fabricators specialize in the production of burn-in PCBs. Some of the leading companies in this field include:

| Company | Location | Specialization |

|---|---|---|

| Epec Engineered Technologies | New Bedford, MA, USA | High-reliability PCBs for aerospace, military, and medical applications |

| Printed Circuits, Inc. | Bloomington, MN, USA | Quick-turn prototypes and high-volume production of burn-in PCBs |

| Sierra Circuits | Sunnyvale, CA, USA | High-complexity PCBs for demanding applications, including burn-in PCBs |

| Lenthor Engineering | Milpitas, CA, USA | Flexible and rigid-flex PCBs, including burn-in PCBs |

| San Francisco Circuits | San Mateo, CA, USA | Quick-turn prototypes and production runs of burn-in PCBs |

These companies offer a range of services, from design consultation to full turn-key manufacturing, to support customers in the development and production of burn-in PCBs.

Considerations for Choosing a Burn-In PCB Fabricator

When selecting a burn-in PCB fabricator, several key factors should be considered:

-

Experience: Choose a fabricator with extensive experience in producing burn-in PCBs for your specific industry or application. This ensures they have the knowledge and expertise to meet your unique requirements.

-

Capabilities: Ensure the fabricator has the necessary equipment and processes in place to manufacture burn-in PCBs to your specifications. This may include the ability to work with high-temperature materials, specialized assembly techniques, and rigorous testing procedures.

-

Quality control: A robust quality control system is essential for ensuring the reliability and consistency of burn-in PCBs. Look for a fabricator with a proven track record of producing high-quality boards and a commitment to continuous improvement.

-

Customer support: Choose a fabricator that offers excellent customer support, from the initial design consultation through to the final delivery of the product. This includes responsive communication, flexible scheduling, and a willingness to work closely with you to meet your needs.

-

Cost: While cost is always a consideration, it should not be the sole deciding factor when choosing a burn-in PCB fabricator. The total cost of ownership, including the potential costs of failures and rework, should be taken into account.

Burn-In PCB Design Considerations

Designing a burn-in PCB requires careful consideration of several factors to ensure reliable operation during the burn-in process:

-

Component selection: Choose components that are rated for the elevated temperatures and voltages of the burn-in process. This may involve working closely with component manufacturers to identify suitable parts.

-

Thermal management: Ensure the PCB layout and design facilitate the dissipation of heat generated during the burn-in process. This may include the use of larger traces, thermal relief pads, and heat sinks.

-

Signal integrity: Maintain signal integrity throughout the burn-in process by carefully routing traces and selecting appropriate materials. This is particularly important for high-speed or high-frequency designs.

-

Test points: Incorporate sufficient test points to allow for monitoring of the PCB and its components during the burn-in process. This facilitates the identification and diagnosis of any issues that may arise.

-

Design for manufacturability: Collaborate with your chosen burn-in PCB fabricator to ensure the design is optimized for manufacturability. This may involve adjusting the layout, selecting alternative materials, or modifying the component placement.

Burn-In PCB Testing

The burn-in testing process is a critical step in ensuring the reliability and longevity of the final product. The specific details of the burn-in process will vary depending on the application and the requirements of the customer but typically involve the following steps:

-

Pre-burn-in testing: Before the burn-in process begins, the PCB and its components are tested to ensure they meet the required specifications. This may include visual inspections, electrical tests, and functional tests.

-

Burn-in chamber setup: The burn-in PCBs are loaded into a specialized burn-in chamber, which is designed to maintain a controlled environment at elevated temperatures and voltages.

-

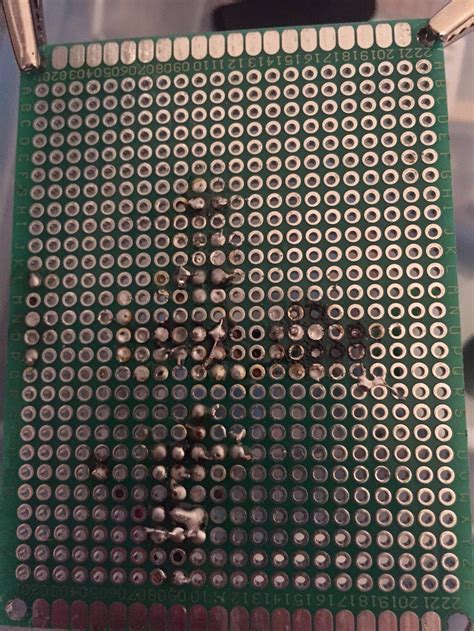

Burn-in cycle: The burn-in PCBs are subjected to the elevated temperatures and voltages for a specified period, typically several hours or days. During this time, the boards are monitored for any signs of failure or degradation.

-

Post-burn-in testing: After the burn-in cycle is complete, the PCBs are removed from the chamber and subjected to additional testing to verify their performance and functionality.

-

Failure analysis: If any failures are identified during the burn-in process, a detailed failure analysis is conducted to determine the root cause and implement corrective actions.

Future Trends in Burn-In PCB Manufacturing

As the demand for high-reliability electronics continues to grow, particularly in industries such as aerospace, military, and medical devices, the burn-in PCB market is expected to expand. Some of the key trends shaping the future of burn-in PCB manufacturing include:

-

Advanced materials: The development of new, high-performance materials, such as advanced ceramics and metal-core PCBs, is expected to enable the production of burn-in PCBs with even greater temperature resistance and reliability.

-

Miniaturization: The trend towards miniaturization in electronics is driving the need for smaller, more compact burn-in PCBs. This requires advanced manufacturing techniques and the use of high-density interconnect (HDI) technology.

-

Increased automation: The increasing use of automation in PCB manufacturing, including the use of robotic assembly and automated optical inspection (AOI), is expected to improve the efficiency and consistency of burn-in PCB production.

-

Environmental sustainability: As with all industries, there is a growing focus on environmental sustainability in burn-in PCB manufacturing. This includes the development of eco-friendly materials, the reduction of waste and emissions, and the implementation of energy-efficient processes.

Frequently Asked Questions (FAQ)

-

What is the purpose of burn-in testing for PCBs?

Burn-in testing is performed to identify and eliminate early-life failures in PCBs and their components. By subjecting the boards to elevated temperatures and voltages for an extended period, potential defects and weaknesses can be identified and addressed before the product is put into service. -

How long does a typical burn-in testing process last?

The duration of a burn-in testing process can vary depending on the specific requirements of the application and the customer. However, a typical burn-in cycle may last several hours or even days, depending on the complexity of the PCB and the level of reliability required. -

Can standard PCBs be used for burn-in testing?

While it is possible to use standard PCBs for burn-in testing, it is not recommended. Burn-in PCBs are specifically designed to withstand the elevated temperatures and voltages of the burn-in process, using high-temperature materials and robust design techniques. Using a standard PCB for burn-in testing may result in damage to the board or its components. -

How do I choose the right burn-in PCB fabricator for my project?

When selecting a burn-in PCB fabricator, consider factors such as their experience in your specific industry or application, their manufacturing capabilities, their quality control processes, and their level of customer support. It’s also important to consider the total cost of ownership rather than just the initial price of the PCBs. -

What should I consider when designing a burn-in PCB?

When designing a burn-in PCB, consider factors such as component selection, thermal management, signal integrity, and the incorporation of sufficient test points. It’s also important to design for manufacturability and to work closely with your chosen burn-in PCB fabricator to ensure the design is optimized for the burn-in process.

Conclusion

Burn-in PCBs play a critical role in ensuring the reliability and longevity of high-performance electronics in demanding applications. By subjecting these boards to elevated temperatures and voltages during the burn-in testing process, potential defects and weaknesses can be identified and eliminated before the product is put into service.

Choosing the right burn-in PCB fabricator is essential for ensuring the success of your project. By considering factors such as experience, capabilities, quality control, customer support, and total cost of ownership, you can select a fabricator that will deliver the high-quality burn-in PCBs you need.

As the demand for high-reliability electronics continues to grow, the burn-in PCB market is expected to expand, driven by advances in materials, manufacturing techniques, and automation. By staying abreast of these trends and working closely with experienced burn-in PCB fabricators, you can ensure your products are built to withstand the rigors of their intended applications.

Leave a Reply