Introduction to PCB Assembly

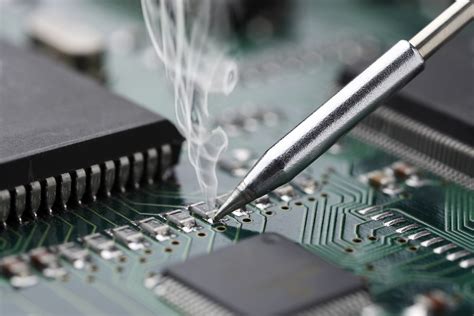

Printed Circuit Board (PCB) assembly is a crucial process in the electronics manufacturing industry. It involves the placement and soldering of electronic components onto a printed circuit board, which serves as the foundation for various electronic devices. Southern California is home to numerous PCB assembly companies, each offering unique services and capabilities. In this article, we will explore the key factors to consider when identifying the top PCB assembly company in Southern California.

Key Factors to Consider When Choosing a PCB Assembly Company

1. Technical Capabilities

When evaluating a PCB assembly company, it is essential to assess their technical capabilities. Look for a company that has experience in assembling PCBs similar to your project requirements. Consider the following aspects:

- SMT (Surface Mount Technology) and THT (Through-Hole Technology) capabilities

- Automated assembly lines and equipment

- High-mix, low-volume production capabilities

- Prototyping and quick-turn services

- PCB design and layout services

A company with a wide range of technical capabilities can handle various project requirements and provide end-to-end solutions.

2. Quality Control and Certifications

Quality is paramount in PCB assembly. A top-notch PCB assembly company should have stringent quality control measures in place to ensure the reliability and performance of the assembled boards. Look for certifications such as:

- ISO 9001 (Quality Management System)

- IPC (Association Connecting Electronics Industries) certifications

- UL (Underwriters Laboratories) recognition

- RoHS (Restriction of Hazardous Substances) compliance

These certifications demonstrate a company’s commitment to quality and adherence to industry standards.

3. Experience and Expertise

The experience and expertise of a PCB assembly company can greatly impact the success of your project. Consider the following factors:

- Years of experience in the industry

- Expertise in specific industries (e.g., aerospace, medical, automotive)

- Technical knowledge and problem-solving skills of the team

- Ability to handle complex and challenging projects

An experienced and knowledgeable team can provide valuable insights and solutions throughout the assembly process.

4. Customer Service and Support

Effective communication and customer support are crucial for a smooth PCB assembly process. Evaluate the company’s responsiveness, communication channels, and willingness to address your concerns. Consider the following aspects:

- Dedicated project management and customer support teams

- Regular progress updates and open lines of communication

- Flexibility in accommodating changes and modifications

- After-sales support and warranty services

A company that prioritizes customer satisfaction and provides excellent support can help ensure the success of your project.

5. Pricing and Lead Times

Cost and lead times are important considerations when choosing a PCB assembly company. While competitive pricing is essential, it should not compromise quality. Look for a company that offers transparent and competitive pricing without hidden costs. Additionally, consider the company’s ability to meet your project’s timeline and deliver the assembled boards within the agreed-upon lead time.

Top PCB Assembly Companies in Southern California

To help you navigate the PCB assembly landscape in Southern California, we have compiled a list of some of the top companies in the region:

| Company | Location | Key Features |

|---|---|---|

| ABC Electronics | San Diego | – ISO 9001 and IPC certified – Specializes in high-mix, low-volume production – Quick-turn prototyping services |

| XYZ Assembly | Los Angeles | – State-of-the-art SMT assembly lines – Expertise in automotive and aerospace industries – In-house PCB design and layout services |

| PCB Solutions | Irvine | – UL recognized and RoHS compliant – Experienced team with over 20 years in the industry – Flexible pricing and lead times |

| Precision Assembly | Santa Ana | – ISO 9001 and IPC certified – Specializes in medical device PCB assembly – Stringent quality control measures |

| Tech Assemblers | Riverside | – Automated THT and SMT assembly capabilities – Expertise in industrial and consumer electronics – Dedicated customer support team |

Note: The companies mentioned above are fictional and used for illustrative purposes only.

FAQ

-

Q: How long does the PCB assembly process typically take?

A: The lead time for PCB assembly varies depending on the complexity of the project, the quantity of boards, and the company’s capacity. On average, prototype assembly can take 1-2 weeks, while production assembly can range from 2-6 weeks. -

Q: Can I provide my own components for PCB assembly?

A: Yes, most PCB assembly companies offer consignment services, where you can provide your own components for assembly. However, it’s important to ensure that the components meet the required specifications and are properly packaged and labeled. -

Q: What is the minimum order quantity (MOQ) for PCB assembly?

A: The MOQ varies from company to company. Some PCB assembly companies specialize in low-volume production and offer MOQs as low as 1-10 pieces, while others may require higher quantities for cost-effectiveness. -

Q: How can I ensure the quality of the assembled PCBs?

A: To ensure the quality of the assembled PCBs, choose a company with strong quality control measures and certifications such as ISO 9001 and IPC. Additionally, request for test reports, inspection reports, and quality assurance documentation from the company. -

Q: What are the common file formats required for PCB assembly?

A: The common file formats required for PCB assembly include Gerber files (RS-274X), drill files (Excellon), bill of materials (BOM), and assembly drawings. Ensure that you provide all the necessary files to the assembly company to avoid delays and errors.

Conclusion

Identifying the top PCB assembly company in Southern California requires careful consideration of various factors such as technical capabilities, quality control, experience, customer service, and pricing. By evaluating these aspects and comparing different companies, you can make an informed decision and choose a reliable partner for your PCB assembly needs.

Remember to communicate your project requirements clearly, ask relevant questions, and establish a strong working relationship with your chosen PCB assembly company. With the right partner by your side, you can bring your electronic products to life with high-quality PCB assembly services in Southern California.

Leave a Reply