What is PCB customization?

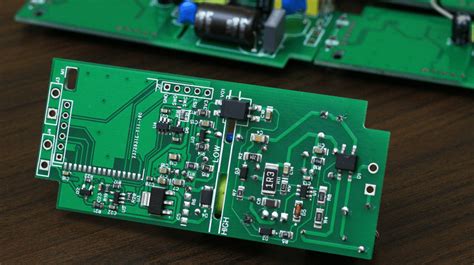

PCB customization refers to the process of designing and manufacturing printed circuit boards that are tailored to meet specific requirements and specifications of a particular application or product. Unlike standard PCBs, which are mass-produced and designed to fit a wide range of applications, customized PCBs are engineered to address unique challenges and optimize performance for a specific purpose.

Benefits of PCB customization

- Enhanced functionality

- Improved reliability

- Cost-effectiveness

- Faster time-to-market

- Competitive advantage

The growing demand for customized PCBs

As technology continues to advance, the demand for customized PCBs has been on the rise. Many industries, including healthcare, aerospace, automotive, and telecommunications, require specialized electronic components that can withstand extreme conditions, perform complex functions, and meet stringent safety standards. Customized PCBs offer a solution to these challenges by providing tailored designs that can address specific requirements and optimize performance.

| Industry | Customization Requirements |

|---|---|

| Healthcare | Miniaturization, biocompatibility, high reliability |

| Aerospace | Lightweight, high-temperature resistance, vibration resistance |

| Automotive | Ruggedness, high-temperature resistance, electromagnetic compatibility |

| Telecommunications | High-speed data transfer, signal integrity, low power consumption |

The role of PCB Assembly services in customization

PCB assembly services play a crucial role in the customization process. These services involve the placement and soldering of electronic components onto the printed circuit board, as well as testing and quality control to ensure that the final product meets the desired specifications. By partnering with experienced and reputable PCB assembly service providers, companies can leverage their expertise and advanced manufacturing capabilities to bring their custom designs to life.

Key considerations when choosing a PCB assembly service provider

- Technical capabilities

- Quality control processes

- Industry certifications and compliance

- Experience and expertise

- Customer support and communication

Advancements in PCB customization technologies

Recent advancements in PCB customization technologies have further enhanced the capabilities of custom PCB design and manufacturing. Some of these technologies include:

- 3D printing for rapid prototyping and complex geometries

- Embedded components for increased functionality and miniaturization

- Flexible and stretchable PCBs for wearable and medical applications

- High-density interconnect (HDI) for improved signal integrity and reduced size

These technologies have enabled the creation of highly specialized and innovative PCBs that can meet the evolving needs of various industries.

Case studies: Successful implementation of customized PCBs

-

Medical device company: A medical device company partnered with a PCB assembly service provider to develop a customized PCB for a wearable health monitoring device. The custom design incorporated miniaturized components, flexible substrates, and biocompatible materials to ensure patient comfort and safety. The result was a highly reliable and accurate device that improved patient outcomes and gained a competitive edge in the market.

-

Aerospace manufacturer: An aerospace manufacturer required a customized PCB that could withstand extreme temperatures and vibrations for use in a satellite. The PCB assembly service provider developed a design using high-temperature materials, conformal coating, and specialized mounting techniques to ensure the PCB’s reliability and performance in harsh conditions. The custom PCB successfully passed all rigorous testing and was integrated into the satellite, contributing to the mission’s success.

Challenges and considerations in PCB customization

While PCB customization offers numerous benefits, it also presents certain challenges and considerations that companies must address:

- Higher upfront costs compared to standard PCBs

- Longer lead times due to custom design and manufacturing processes

- Potential for design errors or incompatibilities

- Intellectual property protection and confidentiality concerns

To mitigate these challenges, it is essential for companies to work closely with their PCB assembly service provider, maintain clear communication, and establish a robust quality control and testing process.

The future of PCB customization

As technology continues to evolve, the demand for customized PCBs is expected to grow. Emerging technologies such as 5G, Internet of Things (IoT), artificial intelligence (AI), and autonomous vehicles will require increasingly complex and specialized electronic components. PCB customization will play a vital role in enabling these technologies and driving innovation across various industries.

Moreover, advancements in materials science, such as the development of graphene and other nanomaterials, may further expand the possibilities of PCB customization. These materials offer unique properties such as high conductivity, flexibility, and thermal management, which can be leveraged to create highly optimized and efficient custom PCBs.

Conclusion

In conclusion, customization in PCB assembly services has indeed become a new approach to obtaining state-of-the-art electronic design and manufacturing solutions. By leveraging the expertise of PCB assembly service providers and the latest technologies in PCB customization, companies can develop highly specialized and optimized electronic components that meet their unique requirements and drive innovation in their respective industries. As technology continues to advance, the importance of PCB customization is only set to grow, making it a critical factor in the success of electronic products and systems.

Frequently Asked Questions (FAQ)

-

What is the difference between standard and customized PCBs?

Standard PCBs are mass-produced and designed to fit a wide range of applications, while customized PCBs are tailored to meet specific requirements and specifications of a particular application or product. -

What industries commonly require customized PCBs?

Industries such as healthcare, aerospace, automotive, and telecommunications often require customized PCBs to address their unique challenges and optimize performance. -

How can I choose the right PCB assembly service provider for my custom PCB project?

When choosing a PCB assembly service provider, consider factors such as technical capabilities, quality control processes, industry certifications, experience, and customer support. -

What are some of the latest technologies used in PCB customization?

Some of the latest technologies used in PCB customization include 3D printing, embedded components, flexible and stretchable PCBs, and high-density interconnect (HDI). -

Are there any challenges or considerations associated with PCB customization?

Yes, PCB customization may involve higher upfront costs, longer lead times, potential design errors, and intellectual property protection concerns. It is essential to work closely with your PCB assembly service provider and establish a robust quality control and testing process to mitigate these challenges.

Leave a Reply