Introduction

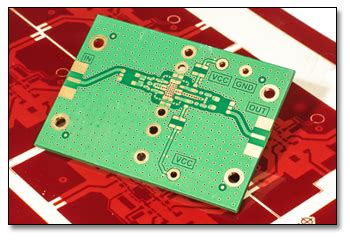

In today’s fast-paced world of technology, companies are constantly striving to innovate and bring new products to market quickly. One key aspect of this process is the ability to rapidly prototype and test new designs, particularly when it comes to printed circuit boards (PCBs). In-house rapid PCB Prototyping has become increasingly important for companies looking to stay ahead of the competition and bring innovative products to market faster.

The Importance of PCB Prototyping

PCB prototyping is a critical step in the product development process. It allows designers and engineers to test and refine their designs before committing to full-scale production. This can save time and money in the long run, as it allows for the identification and correction of any issues early on in the development cycle.

Benefits of PCB Prototyping

- Early identification of design flaws

- Opportunity to test and refine functionality

- Ability to make changes quickly and efficiently

- Reduced risk of costly production errors

- Faster time-to-market for new products

Advantages of In-House PCB Prototyping

While outsourcing PCB prototyping to third-party manufacturers is an option, there are several advantages to bringing this process in-house.

Faster Turnaround Times

One of the biggest advantages of in-house PCB prototyping is the ability to achieve faster turnaround times. When outsourcing, companies are at the mercy of the manufacturer’s schedule and may have to wait weeks or even months for prototypes to be delivered. With in-house prototyping, designers can create and test prototypes in a matter of days or even hours.

Greater Control Over the Process

In-house prototyping also gives companies greater control over the entire process. They can make changes on the fly and iterate quickly without having to communicate back and forth with an external manufacturer. This level of control can be particularly important when working on sensitive or confidential projects.

Cost Savings

While there is an initial investment required to set up an in-house PCB prototyping lab, it can lead to significant cost savings in the long run. Outsourcing prototypes can be expensive, particularly when multiple iterations are required. With in-house prototyping, companies can produce prototypes at a lower cost per unit and avoid the markup charged by external manufacturers.

Improved Collaboration

In-house PCB prototyping also promotes collaboration between different teams within an organization. Designers, engineers, and product managers can work together closely to refine designs and make improvements in real-time. This level of collaboration is more difficult to achieve when working with an external manufacturer.

Setting Up an In-House PCB Prototyping Lab

Setting up an in-house PCB prototyping lab requires an initial investment in equipment and training. However, the long-term benefits can far outweigh the upfront costs.

Essential Equipment

To set up a basic PCB prototyping lab, companies will need the following equipment:

| Equipment | Description |

|---|---|

| PCB Printer | Used to print circuit patterns onto PCB substrate material |

| Etching Tank | Used to remove unwanted copper from the PCB substrate |

| Drill Press | Used to drill holes in the PCB for component placement |

| Pick and Place Machine | Used to place surface mount components onto the PCB |

| Reflow Oven | Used to solder components onto the PCB |

Software and Design Tools

In addition to hardware, companies will also need to invest in software and design tools for PCB prototyping. Some popular options include:

- Altium Designer

- Eagle PCB

- KiCad

- Fusion 360

Training and Skill Development

To get the most out of an in-house PCB prototyping lab, companies will need to invest in training and skill development for their staff. This may include sending employees to workshops or conferences, or bringing in outside experts to provide on-site training.

Best Practices for In-House PCB Prototyping

To ensure the success of an in-house PCB prototyping lab, companies should follow some best practices:

- Establish clear protocols and workflows to ensure consistency and efficiency.

- Regularly calibrate and maintain equipment to ensure accurate results.

- Implement version control and documentation practices to track changes and improvements over time.

- Foster a culture of experimentation and iteration, encouraging designers to test and refine their ideas.

- Collaborate closely with other teams, such as product management and manufacturing, to ensure prototypes meet real-world needs.

Future Trends in PCB Prototyping

As technology continues to evolve, so too will the world of PCB prototyping. Some trends to watch include:

3D Printing

3D printing technology is increasingly being used for PCB prototyping, allowing for the creation of complex shapes and structures that would be difficult or impossible to achieve with traditional manufacturing methods.

Artificial Intelligence and Machine Learning

AI and machine learning are being used to optimize PCB designs and predict potential issues before prototypes are even created. This can help companies save time and resources by catching problems early on.

Increased Automation

As PCB prototyping equipment becomes more sophisticated, we can expect to see increased automation of the prototyping process. This could include the use of robots for pick and place assembly, as well as automated testing and quality control.

Conclusion

In-house rapid PCB prototyping is a game-changer for companies looking to innovate and bring new products to market quickly. By bringing the prototyping process in-house, companies can achieve faster turnaround times, greater control over the process, cost savings, and improved collaboration. While there is an initial investment required to set up a prototyping lab, the long-term benefits can far outweigh the costs. As technology continues to evolve, we can expect to see even more exciting developments in the world of PCB prototyping in the years to come.

Frequently Asked Questions

What is PCB prototyping?

PCB prototyping is the process of creating a physical prototype of a printed circuit board (PCB) design. This allows designers to test and refine their designs before committing to full-scale production.

Why is in-house PCB prototyping important?

In-house PCB prototyping allows companies to achieve faster turnaround times, greater control over the process, cost savings, and improved collaboration compared to outsourcing the prototyping process.

What equipment is needed for in-house PCB prototyping?

To set up a basic PCB prototyping lab, companies will need equipment such as a PCB printer, etching tank, drill press, pick and place machine, and reflow oven, as well as software and design tools.

What are some best practices for in-house PCB prototyping?

Best practices for in-house PCB prototyping include establishing clear protocols and workflows, regularly calibrating and maintaining equipment, implementing version control and documentation practices, fostering a culture of experimentation and iteration, and collaborating closely with other teams.

What are some future trends in PCB prototyping?

Some future trends in PCB prototyping include the use of 3D printing technology, artificial intelligence and machine learning for design optimization, and increased automation of the prototyping process.

Leave a Reply