Introduction to PCB Assembly Costs

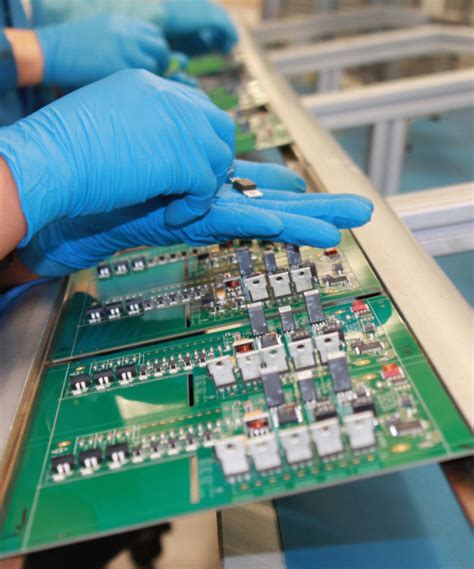

Printed Circuit Board (PCB) assembly is a crucial process in the electronics manufacturing industry. The cost of PCB assembly can significantly impact the overall cost of the final product. Understanding the factors that affect PCB assembly costs and implementing cost-saving strategies can help manufacturers optimize their production processes and remain competitive in the market.

In this article, we will explore the various factors that influence PCB Assembly Costs and provide valuable tips on how to save costs without compromising on quality.

Factors Affecting PCB Assembly Costs

1. PCB Design Complexity

The complexity of the PCB design is one of the primary factors that affect assembly costs. A more complex design with a higher number of layers, smaller trace widths, and tighter tolerances will require more advanced manufacturing techniques and specialized equipment, leading to increased costs.

PCB Layer Count and Cost

| Number of Layers | Relative Cost |

|---|---|

| 1-2 | Low |

| 4 | Medium |

| 6-8 | High |

| 10+ | Very High |

2. Component Selection

The choice of components used in the PCB assembly process can significantly impact the overall cost. Using specialized or hard-to-find components may increase the cost due to limited availability and higher prices. Opting for standard, readily available components can help reduce costs.

3. Order Quantity

The quantity of PCBs ordered plays a crucial role in determining the assembly cost per unit. Larger order quantities often result in lower per-unit costs due to economies of scale. Manufacturers can benefit from bulk discounts on components and more efficient use of production resources when producing larger batches.

Order Quantity and Cost Per Unit

| Order Quantity | Relative Cost Per Unit |

|---|---|

| 1-100 | High |

| 101-500 | Medium |

| 501-1000 | Low |

| 1000+ | Very Low |

4. Surface Mount Technology (SMT) vs. Through-Hole Technology (THT)

The choice between SMT and THT assembly methods can impact the cost of PCB assembly. SMT is generally more cost-effective for high-volume production, as it allows for automated assembly processes. THT, on the other hand, may be more suitable for low-volume or prototype projects, but it typically involves more manual labor, resulting in higher costs.

5. Quality Control and Testing

Implementing comprehensive quality control measures and thorough testing procedures is essential to ensure the reliability and functionality of the assembled PCBs. However, these processes can add to the overall cost of assembly. Balancing the need for quality with cost considerations is crucial to optimize the manufacturing process.

Tips to Save PCB Assembly Costs

1. Optimize PCB Design

Simplifying the PCB design can lead to significant cost savings. Consider the following design optimizations:

- Minimize the number of layers

- Use standard component sizes and packages

- Avoid unnecessary features and complexity

- Ensure proper design for manufacturability (DFM)

2. Choose Cost-Effective Components

Selecting cost-effective components can help reduce the overall assembly cost without compromising on functionality. Consider the following tips:

- Use standard, readily available components

- Avoid using specialized or obsolete components

- Opt for surface mount components when possible

- Consider alternative suppliers for better pricing

3. Plan for Larger Order Quantities

Planning for larger order quantities can result in significant cost savings due to economies of scale. Consider the following strategies:

- Forecast demand accurately to determine optimal order quantities

- Negotiate bulk discounts with component suppliers

- Optimize inventory management to avoid excess stock or shortages

4. Automate Assembly Processes

Investing in automated assembly processes, such as SMT assembly lines, can greatly reduce labor costs and improve production efficiency. Automation is particularly beneficial for high-volume production runs and can help maintain consistent quality.

5. Collaborate with Reliable PCB Assembly Partners

Partnering with reputable and experienced PCB assembly service providers can help optimize costs and ensure high-quality results. Consider the following when selecting an assembly partner:

- Look for providers with a proven track record of quality and reliability

- Evaluate their technical capabilities and manufacturing facilities

- Consider their pricing structure and cost-saving initiatives

- Assess their ability to scale production to meet your needs

Frequently Asked Questions (FAQ)

-

Q: How can I estimate the cost of PCB assembly for my project?

A: To estimate the cost of PCB assembly, consider factors such as PCB design complexity, component selection, order quantity, assembly technology (SMT vs. THT), and quality control requirements. Obtain quotes from multiple PCB assembly service providers to compare pricing and services. -

Q: What is the minimum order quantity (MOQ) for PCB assembly?

A: The minimum order quantity for PCB assembly varies among service providers. Some providers offer low MOQs for prototype and small-batch production, while others may require higher MOQs for cost-effective assembly. It’s best to discuss your specific requirements with potential assembly partners. -

Q: How can I ensure the quality of my assembled PCBs while keeping costs low?

A: To ensure quality while keeping costs low, consider the following: - Optimize your PCB design for manufacturability

- Choose reliable and cost-effective components

- Partner with reputable PCB assembly service providers

- Implement appropriate quality control measures and testing procedures

-

Regularly review and optimize your manufacturing processes

-

Q: What is the typical turnaround time for PCB assembly?

A: The turnaround time for PCB assembly depends on various factors, such as the complexity of the design, order quantity, and the service provider’s capacity. Typical turnaround times can range from a few days to several weeks. Discuss your timeline requirements with your assembly partner to ensure they can meet your needs. -

Q: Can I save costs by providing my own components for PCB assembly?

A: Providing your own components, known as consignment inventory, can potentially save costs in some cases. However, it’s essential to ensure that the components meet the required specifications and are available in sufficient quantities. Consult with your PCB assembly service provider to determine if consignment inventory is a viable option for your project.

Conclusion

Understanding the factors that affect PCB assembly costs and implementing cost-saving strategies is crucial for manufacturers to remain competitive in the market. By optimizing PCB design, selecting cost-effective components, planning for larger order quantities, automating assembly processes, and collaborating with reliable assembly partners, manufacturers can significantly reduce costs without compromising on quality.

As the electronics industry continues to evolve, staying informed about the latest cost-saving techniques and technologies is essential. By adopting a proactive approach to cost management and continuously seeking opportunities for optimization, manufacturers can successfully navigate the challenges of PCB assembly and deliver high-quality products at competitive prices.

Leave a Reply