Introduction to Glass Transition Temperature

Glass transition temperature, commonly referred to as Tg, is a critical property of materials used in printed circuit boards (PCBs). It represents the temperature range where a polymer transitions from a hard, glassy state to a soft, rubbery state. Understanding Tg is essential for selecting appropriate materials for PCB manufacturing to ensure reliability and performance under various operating conditions.

Definition of Glass Transition Temperature

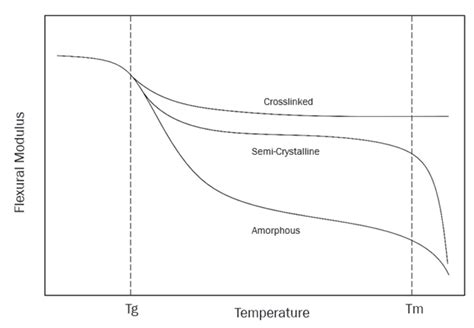

Glass transition temperature is defined as the temperature at which a polymer transitions from a hard, brittle, glassy state to a soft, flexible, rubbery state. This transition occurs over a range of temperatures rather than at a single point. Below Tg, the polymer is in a glassy state, characterized by a high modulus of elasticity and low molecular mobility. Above Tg, the polymer enters a rubbery state, exhibiting increased molecular mobility and a significant decrease in modulus.

Importance of Tg in PCB Materials

Tg is a crucial factor in determining the suitability of materials for PCB Applications. It directly affects the mechanical, thermal, and electrical properties of the PCB. The choice of materials with appropriate Tg values ensures that the PCB can withstand the stresses and strains encountered during manufacturing, assembly, and operation.

Key reasons why Tg is important in PCB materials:

-

Mechanical stability: Materials with higher Tg values maintain their mechanical properties over a wider temperature range, reducing the risk of deformation or damage during manufacturing and use.

-

Thermal resistance: PCBs are often exposed to elevated temperatures during soldering, reflow, and operation. Materials with higher Tg values can withstand these thermal stresses without softening or degrading.

-

Dimensional stability: Changes in temperature can cause PCB materials to expand or contract. Materials with higher Tg values exhibit lower thermal expansion coefficients, minimizing dimensional changes and ensuring better reliability.

-

Electrical performance: The Tg of a material can influence its dielectric properties, such as Dielectric Constant and loss tangent. Maintaining stable electrical properties over the operating temperature range is crucial for signal integrity and overall PCB performance.

Common PCB Materials and Their Tg Values

PCBs are manufactured using a variety of materials, each with its own set of properties and Tg values. The choice of material depends on the specific requirements of the application, such as operating temperature, electrical performance, and cost. Here are some commonly used PCB materials and their typical Tg values:

| Material | Tg Range (°C) |

|---|---|

| FR-4 (Standard) | 130 – 140 |

| FR-4 (High Tg) | 170 – 180 |

| Polyimide | 250 – 400 |

| BT Epoxy | 180 – 210 |

| Cyanate Ester | 250 – 290 |

| PTFE (Teflon) | 327 |

| Rogers 4003C | >280 |

| Rogers 4350B | >280 |

FR-4

FR-4 is the most widely used PCB material, known for its good mechanical and electrical properties, as well as its cost-effectiveness. Standard FR-4 has a Tg range of 130°C to 140°C, making it suitable for most general-purpose applications. High Tg FR-4 variants, with Tg values between 170°C and 180°C, are available for more demanding applications that require higher thermal resistance.

Polyimide

Polyimide is a high-performance polymer known for its excellent thermal stability, chemical resistance, and mechanical strength. With a Tg range of 250°C to 400°C, polyimide is well-suited for applications that require operation at elevated temperatures or exposure to harsh environments. However, polyimide is more expensive than FR-4 and can be more challenging to process.

BT Epoxy

Bismaleimide-Triazine (BT) epoxy is a popular choice for high-density interconnect (HDI) PCBs and chip packaging substrates. BT epoxy offers a higher Tg range (180°C to 210°C) compared to standard FR-4, along with good mechanical and electrical properties. It is often used in applications that require higher thermal resistance and dimensional stability.

Cyanate Ester

Cyanate ester is a high-performance thermoset polymer with excellent thermal and electrical properties. With a Tg range of 250°C to 290°C, cyanate ester is well-suited for applications that demand high thermal stability and low dielectric loss. It is commonly used in high-frequency and high-speed digital applications, such as radar systems and telecommunications equipment.

PTFE (Teflon)

Polytetrafluoroethylene (PTFE), also known as Teflon, is a fluoropolymer with exceptional thermal and chemical resistance. PTFE has a high Tg of 327°C, making it suitable for applications that require operation at very high temperatures. Additionally, PTFE exhibits excellent dielectric properties, low moisture absorption, and low dissipation factor, making it ideal for high-frequency and microwave applications.

Rogers Materials

Rogers Corporation offers a range of high-performance PCB materials designed for demanding applications. Two popular examples are Rogers 4003C and Rogers 4350B, both of which have Tg values exceeding 280°C. These materials exhibit excellent thermal stability, low dielectric loss, and controlled dielectric constant, making them well-suited for high-frequency and high-speed digital applications.

Factors Affecting Tg in PCB Materials

Several factors can influence the glass transition temperature of PCB materials. Understanding these factors is important for selecting the appropriate material and optimizing the PCB design for specific applications.

Chemical Composition

The chemical composition of a polymer plays a significant role in determining its Tg. The type and arrangement of monomers, the presence of functional groups, and the degree of crosslinking all contribute to the Tg value. In general, polymers with higher molecular weights, greater chain stiffness, and increased crosslinking density tend to have higher Tg values.

Additives and Fillers

PCB materials often incorporate additives and fillers to modify their properties. These additives can include flame retardants, coupling agents, and reinforcing fibers. The type and amount of additives used can affect the Tg of the material. For example, the addition of ceramic fillers can increase the Tg and improve thermal conductivity, while certain flame retardants may lower the Tg.

Manufacturing Process

The manufacturing process used to produce the PCB material can also impact its Tg. Factors such as the curing temperature, curing time, and pressure applied during lamination can influence the degree of crosslinking and the final Tg value. Proper control and optimization of the manufacturing process are essential to achieve consistent and reliable Tg values.

Environmental Conditions

Exposure to environmental conditions, such as temperature, humidity, and chemical agents, can affect the Tg of PCB materials over time. Prolonged exposure to high temperatures or moisture can lead to changes in the polymer structure, resulting in a decrease in Tg. Similarly, exposure to certain chemicals can degrade the material and alter its Tg. Selecting materials with appropriate chemical resistance and protecting the PCB from harsh environmental conditions can help maintain the desired Tg throughout the product’s lifecycle.

Measuring and Testing Tg in PCB Materials

Accurate measurement and testing of Tg are essential for ensuring the quality and reliability of PCB materials. Several techniques are commonly used to determine the Tg of polymers, each with its own advantages and limitations.

Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (DSC) is a widely used technique for measuring the Tg of polymers. In DSC, a small sample of the material is heated at a controlled rate, and the heat flow into or out of the sample is measured as a function of temperature. The Tg is identified as a step change in the heat flow curve, indicating a change in the material’s heat capacity.

DSC offers several advantages:

– High accuracy and precision

– Small sample size requirements

– Ability to measure other thermal properties, such as melting point and crystallinity

However, DSC also has some limitations:

– Requires careful sample preparation and calibration

– May not detect subtle transitions or overlapping transitions

– Limited to small sample sizes

Dynamic Mechanical Analysis (DMA)

Dynamic Mechanical Analysis (DMA) is another technique used to determine the Tg of polymers. In DMA, a sample is subjected to a sinusoidal stress, and the resulting strain is measured as a function of temperature. The Tg is identified as a peak in the loss modulus curve or a drop in the storage modulus curve.

DMA offers several advantages:

– Ability to measure mechanical properties in addition to Tg

– Sensitivity to subtle transitions and secondary transitions

– Capability to test larger sample sizes and finished products

However, DMA also has some limitations:

– Requires specialized equipment and expertise

– May be affected by sample geometry and clamping conditions

– Limited to materials that can be formed into suitable test specimens

Thermomechanical Analysis (TMA)

Thermomechanical Analysis (TMA) is a technique that measures the dimensional changes of a sample as a function of temperature. In TMA, a small force is applied to the sample, and the resulting deformation is monitored while the temperature is varied. The Tg is identified as a change in the slope of the dimensional change curve.

TMA offers several advantages:

– Ability to measure dimensional stability and thermal expansion

– Sensitivity to subtle transitions and secondary transitions

– Capability to test finished products and assemblies

However, TMA also has some limitations:

– Requires careful sample preparation and calibration

– May be affected by sample geometry and contact conditions

– Limited to materials that exhibit measurable dimensional changes

Designing PCBs with Consideration for Tg

When designing PCBs, it is important to consider the Tg of the materials used and how it may affect the performance and reliability of the final product. Here are some key considerations for designing PCBs with Tg in mind:

Material Selection

Choose PCB materials with Tg values that are appropriate for the intended application and operating conditions. Consider factors such as the maximum operating temperature, thermal cycling requirements, and environmental exposure. For applications that require high thermal stability or resistance to elevated temperatures, select materials with higher Tg values, such as polyimide, cyanate ester, or high Tg FR-4 variants.

Layer Stack-Up Design

When designing the layer stack-up of a PCB, consider the Tg of the materials used in each layer. Ensure that the materials with the lowest Tg values are not placed in layers that may be exposed to the highest temperatures during manufacturing or operation. For example, in a multi-layer PCB, it may be advantageous to use higher Tg materials for the outer layers and standard FR-4 for the inner layers.

Thermal Management

Incorporate appropriate thermal management techniques to minimize the temperature rise in the PCB during operation. This can include the use of thermal vias, heat sinks, and proper component placement. By reducing the maximum temperature experienced by the PCB, you can help ensure that the materials remain below their Tg and maintain their desired properties.

Manufacturing Process Optimization

Work closely with your PCB Manufacturer to optimize the manufacturing process for the selected materials. This may involve adjusting parameters such as the lamination temperature, pressure, and time to achieve the desired Tg and other properties. Proper process control and monitoring can help ensure consistent and reliable results.

Testing and Qualification

Conduct thorough testing and qualification of the PCB design to verify its performance and reliability under the expected operating conditions. This may include thermal cycling tests, high-temperature storage tests, and mechanical stress tests. By validating the PCB design through testing, you can identify any potential issues related to Tg and make necessary adjustments before production.

Frequently Asked Questions (FAQ)

-

What is the difference between Tg and melting point?

Tg and melting point are two distinct thermal properties of materials. Tg represents the temperature range where a polymer transitions from a glassy to a rubbery state, while the melting point is the temperature at which a crystalline material transitions from a solid to a liquid state. Not all polymers have a melting point, but all polymers exhibit a glass transition temperature. -

Can Tg be increased after the manufacturing of a PCB?

Once a PCB is manufactured, it is not possible to increase its Tg without altering the material composition or processing conditions. The Tg is an inherent property of the material and is determined during the manufacturing process. To achieve a higher Tg, you would need to select a different material or modify the manufacturing process before production. -

How does moisture affect the Tg of PCB materials?

Moisture can have a plasticizing effect on polymers, leading to a decrease in Tg. When a polymer absorbs moisture, the water molecules can disrupt the intermolecular interactions and increase the molecular mobility, effectively lowering the Tg. To minimize the impact of moisture, PCB materials with low moisture absorption rates are preferred, and proper storage and handling conditions should be maintained. -

Can Tg be used as the sole criterion for selecting PCB materials?

While Tg is an important factor in selecting PCB materials, it should not be used as the sole criterion. Other properties, such as dielectric constant, dissipation factor, thermal conductivity, and mechanical strength, also play crucial roles in determining the suitability of a material for a specific application. It is essential to consider a combination of properties and balance them based on the requirements of the intended use case. -

How does the Tg of a PCB material affect its long-term reliability?

The Tg of a PCB material can have a significant impact on its long-term reliability. Materials with higher Tg values are generally more resistant to thermal degradation, mechanical stress, and dimensional changes over time. When a PCB operates at temperatures close to or above its Tg, the material may soften, deform, or experience increased thermal expansion, leading to potential reliability issues such as delamination, warpage, or cracking. Selecting materials with appropriate Tg values for the expected operating conditions can help ensure long-term reliability of the PCB.

Conclusion

Glass transition temperature (Tg) is a critical property of PCB materials that determines their performance and reliability under various operating conditions. Understanding Tg and its impact on PCB design is essential for selecting appropriate materials and optimizing the manufacturing process. By considering factors such as the intended application, operating temperature, and environmental exposure, designers can make informed decisions when choosing PCB materials with suitable Tg values.

Measuring and testing Tg using techniques like DSC, DMA, and TMA provides valuable insights into the thermal properties of PCB materials. These methods allow for accurate determination of Tg and help ensure the quality and consistency of the materials used in PCB manufacturing.

When designing PCBs, it is crucial to consider Tg in conjunction with other material properties, such as dielectric constant, thermal conductivity, and mechanical strength. By selecting materials with appropriate Tg values, optimizing the layer stack-up design, implementing thermal management techniques, and conducting thorough testing and qualification, designers can create PCBs that meet the performance and reliability requirements of their intended applications.

As the demands for higher performance, increased reliability, and operation in challenging environments continue to grow, the importance of understanding and leveraging Tg in PCB design will only become more significant. By staying informed about the latest developments in PCB materials and design practices related to Tg, engineers and manufacturers can stay ahead of the curve and deliver innovative, reliable, and high-quality PCBs for a wide range of industries and applications.

Leave a Reply